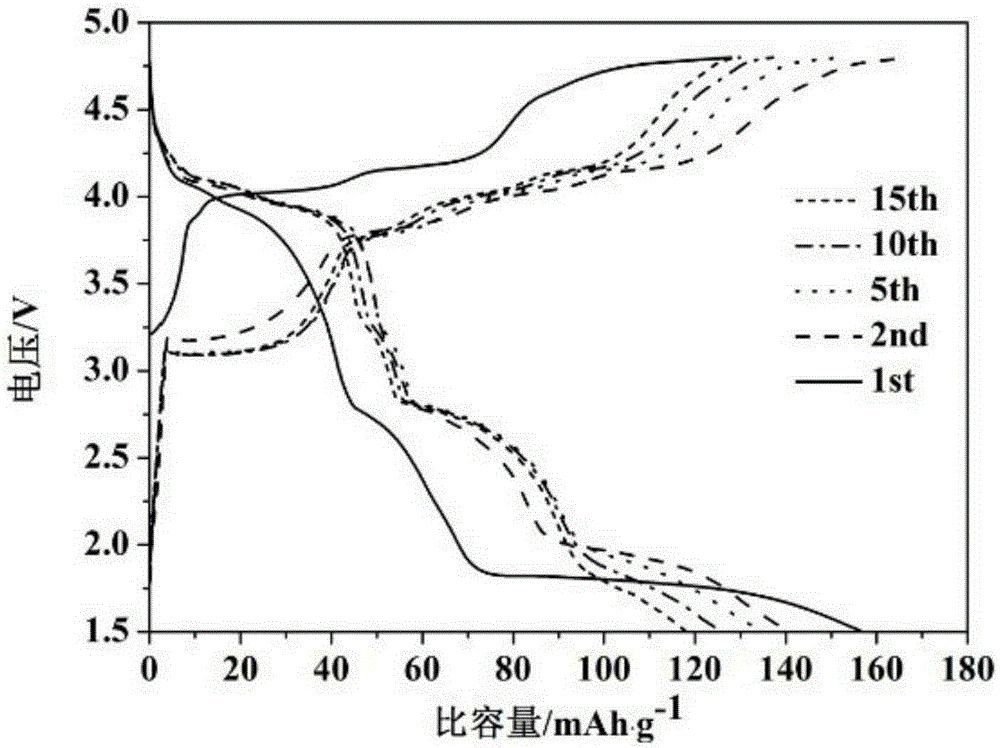

Synthetic method for novel anode material, namely manganese lithium stannate, for lithium ion battery

A lithium-ion battery, lithium manganese stannate technology, applied in battery electrodes, batteries, positive electrodes, etc., can solve the problems of limiting the competitiveness of high-energy batteries, limited reserves of cobalt and nickel resources, and low energy density, and achieve electrochemical performance. Excellent, high equipment utilization, uniform raw material composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of synthetic method of novel lithium ion battery cathode material manganese stannate lithium, comprises the following steps:

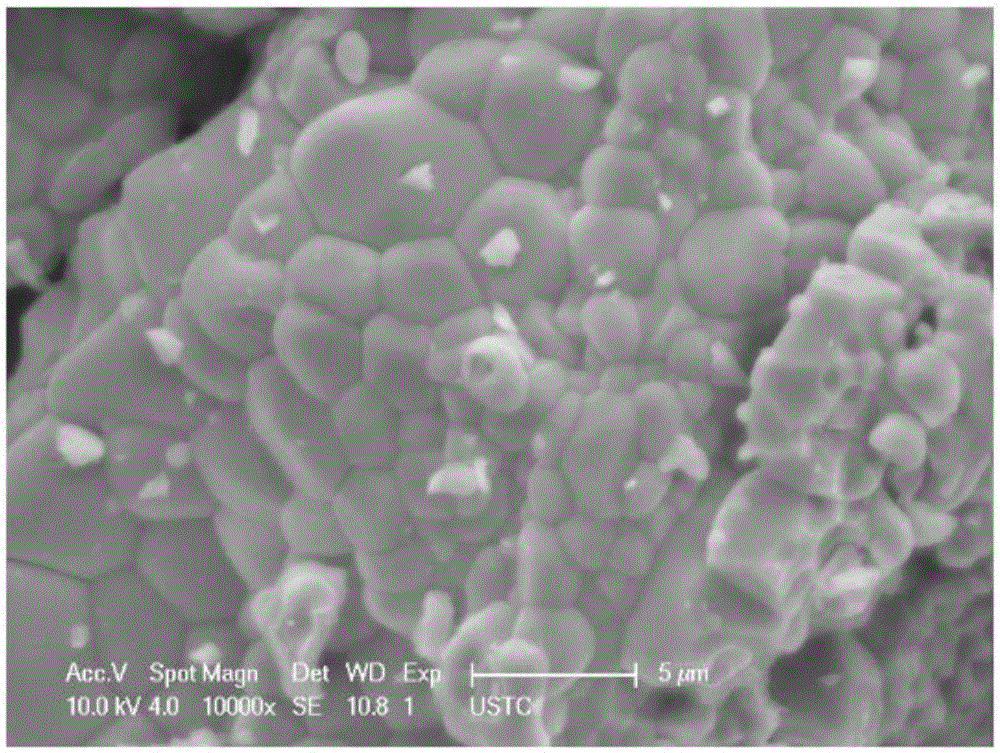

[0026] (1) Take lithium hydroxide 4.2g, manganese acetate dihydrate 18.61g and crystalline tin tetrachloride 35.06g according to the molar ratio Li:Mn:Sn=1.1:1:1, according to the total weight of lithium source, manganese source and tin source 1.0% Add 0.6g PEG20000 as a dispersant, add 90mL of absolute ethanol as a dispersion medium, and after ball milling for 6 hours to form a uniform slurry with a solid content of 45%, dry at 80°C for 24 hours to obtain a precursor of lithium manganese stannate ;

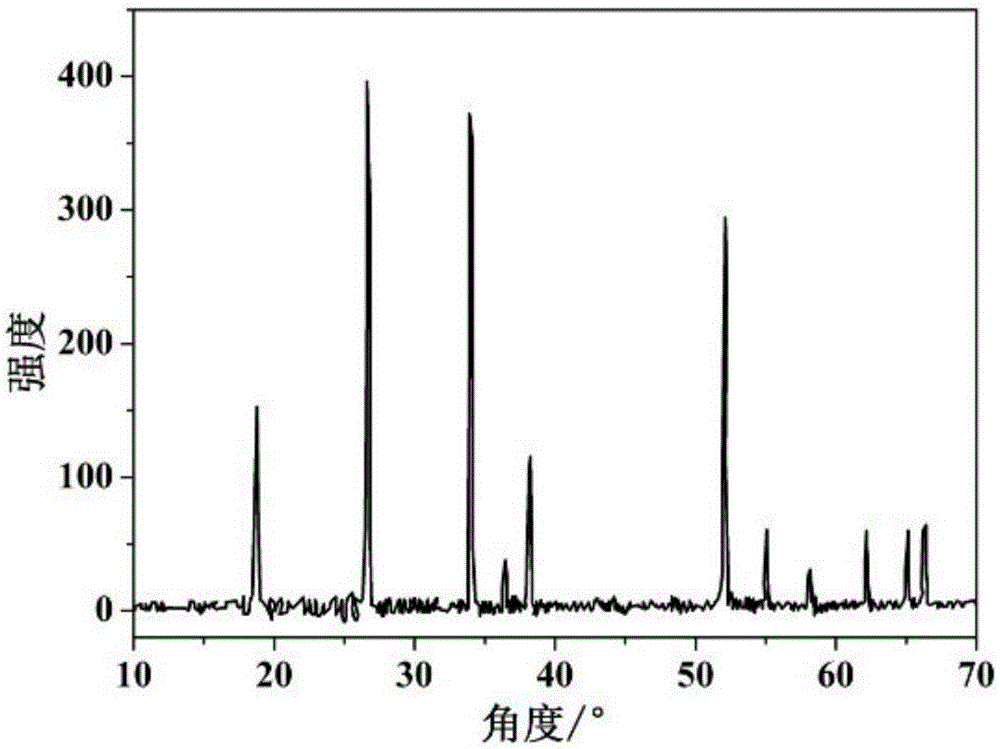

[0027] (2) Pre-calcining the precursor obtained in step (1) in an air atmosphere at 400°C for 10 hours to obtain a lithium manganese stannate calcined material composed of lithium oxide, manganese oxide and tin dioxide;

[0028] (3) After grinding and pulverizing the lithium manganese stannate pre-sintered material, sintering at a high temp...

Embodiment 2

[0030] A kind of synthetic method of novel lithium ion battery cathode material manganese stannate lithium, comprises the following steps:

[0031] (1) Weigh 3.8g of lithium hydroxide, 18.61g of manganese acetate dihydrate and 35.06g of crystalline tin tetrachloride according to the molar ratio Li:Mn:Sn=1.0:1:1, according to 1.0% of the weight of lithium source, manganese source and tin source % Add 0.6g PEG4000 as a dispersant, add 90mL of absolute ethanol as a dispersion medium, form a uniform slurry with a solid content of 45% after ball milling for 6 hours, then dry at 80°C for 24 hours to obtain a lithium manganese stannate precursor;

[0032] (2) Pre-calcining the precursor obtained in step (1) in an air atmosphere at 500°C for 10 hours to obtain a lithium manganese stannate calcined material composed of lithium oxide, manganese oxide and tin dioxide;

[0033] (3) Grinding and pulverizing the lithium manganese stannate pre-sintered material, and then sintering at a high ...

Embodiment 3

[0035] A kind of synthetic method of novel lithium ion battery cathode material manganese stannate lithium, comprises the following steps:

[0036] (1) Weigh 4.2g of lithium hydroxide, 18.61g of manganese acetate dihydrate and 35.06g of crystalline tin tetrachloride according to the molar ratio Li:Mn:Sn=1.1:1:1, according to 1.0% of the weight of lithium source, manganese source and tin source % Add 0.6g PEG20000 as a dispersant, add 90mL of absolute ethanol as a dispersion medium, and after ball milling for 6 hours to form a uniform slurry with a solid content of 45%, dry at 80°C for 24 hours to obtain a lithium manganese stannate precursor;

[0037] (2) Pre-calcining the precursor obtained in step (1) in an air atmosphere at 400°C for 10 hours to obtain a lithium manganese stannate calcined material composed of lithium oxide, manganese oxide and tin dioxide;

[0038] (3) After grinding and pulverizing the lithium manganese stannate pre-sintered material, sintering at a high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com