Preparation method for separating lysozyme by amino-functionalized magnetic nanoparticles

A technology of magnetic nanoparticles and amino functionalization, applied in biochemical equipment and methods, chemical instruments and methods, enzymes, etc., can solve problems such as backward production technology and lysozyme scale gap, and achieve small impact, large adsorption capacity, Simple effect of extraction separation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

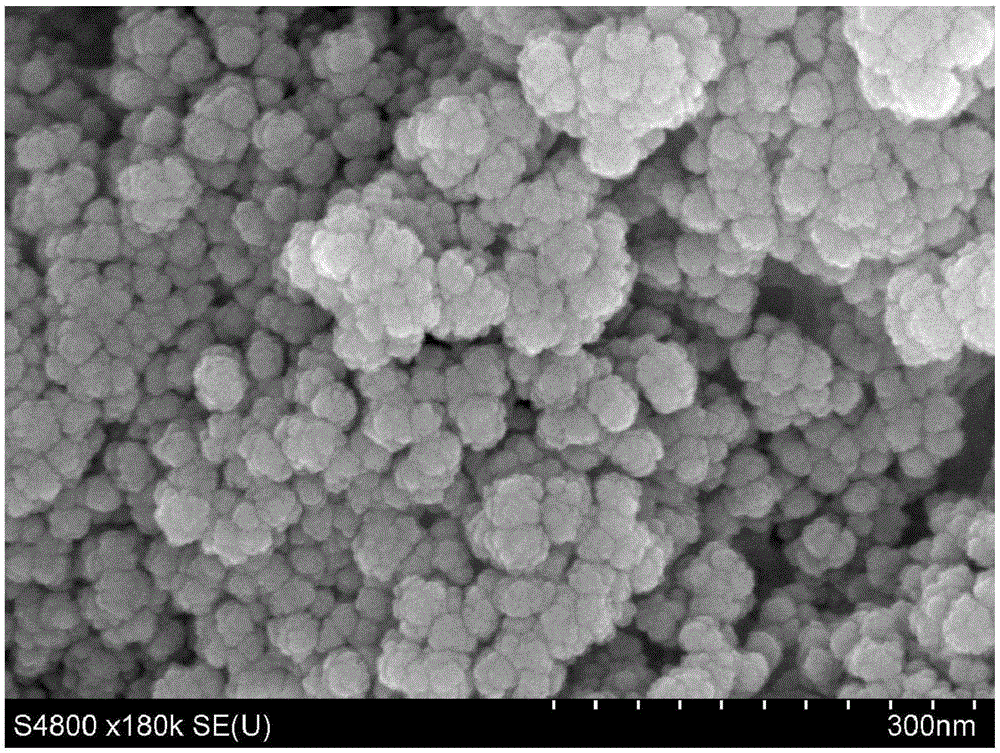

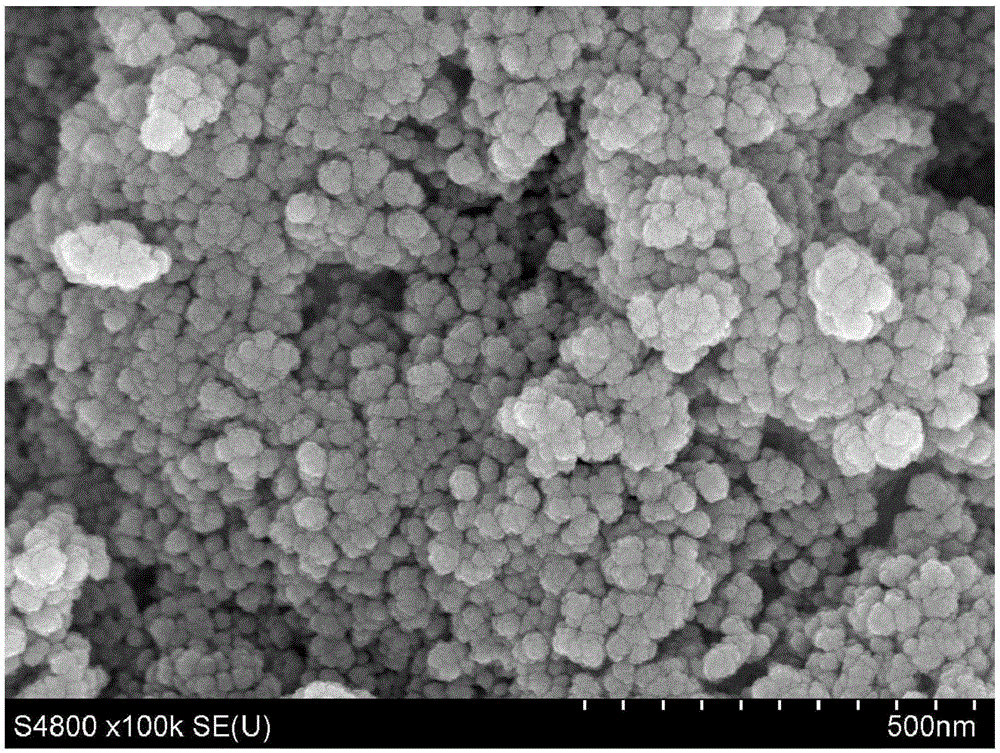

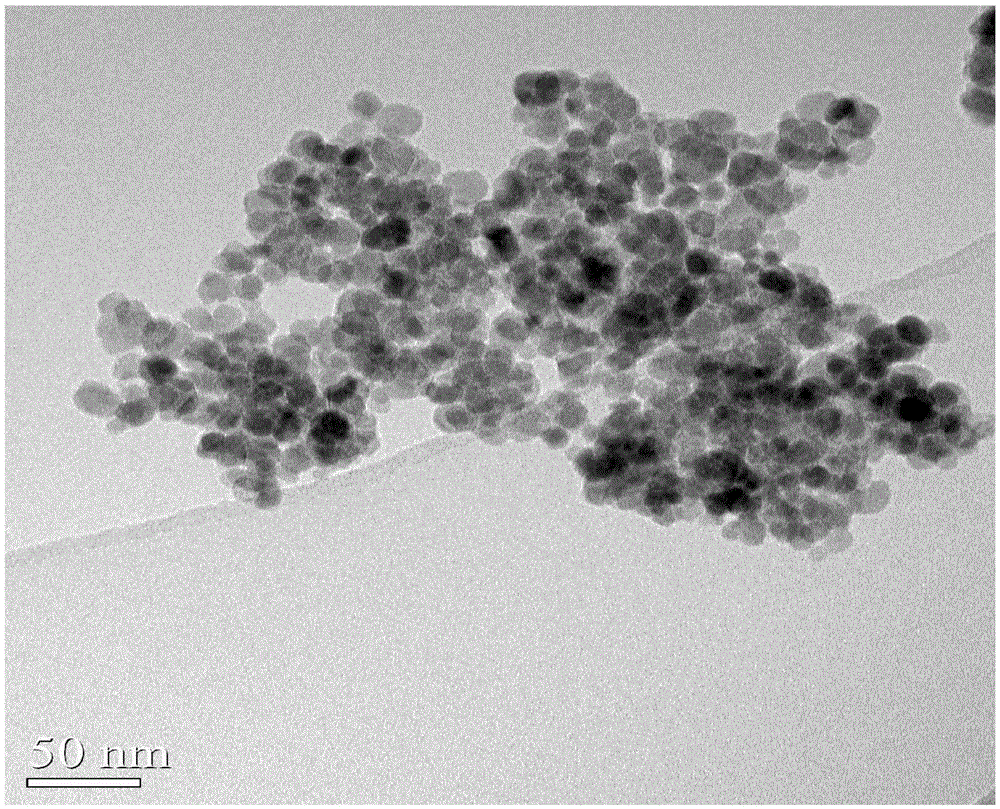

[0021] 3g FeCl 2 ·4H 2 O and 8.1g FeCl 3 ·6H 2 O was dissolved in 200 mL of deionized water, at room temperature, under nitrogen protection, 85 mL of 25% ammonia water was added dropwise to it, stirred for 30 min, then heated to 70 °C and continued to stir for 30 min, cooled to room temperature, collected with a magnet, and washed with deionized water for several times Rinse and dry to get magnetic Fe 3 O 4 Nanoparticles. Put 4g of magnetic Fe 3 O 4 The nanoparticles were placed in 50 mL of anhydrous toluene and subjected to ultrasound for 15 min. Under nitrogen protection, 22 nmol of 3-aminopropyltriethoxysilane (APTES) was added and stirred at room temperature for 5 h. After repeated rinsing and drying, amino-functionalized magnetic nanoparticles can be obtained.

[0022] Take the egg white of fresh eggs and phosphate buffer solution (20nmol) and dilute them at a volume ratio of 1:1, and then continuously stir the reaction in an ice-water bath for 6 hours. Insoluble...

Embodiment 2

[0025] 3g FeCl 2 ·4H 2 O and 8.1g FeCl 3 ·6H 2 O was dissolved in 200 mL of deionized water, at room temperature, under nitrogen protection, 85 mL of 25% ammonia water was added dropwise to it, stirred for 30 min, then heated to 70 °C and continued to stir for 30 min, cooled to room temperature, collected with a magnet, and washed with deionized water for several times Rinse and dry to get magnetic Fe 3 O 4 Nanoparticles. Put 4g of magnetic Fe 3 O 4 The nanoparticles were placed in 50 mL of anhydrous toluene and subjected to ultrasound for 15 min. Under nitrogen protection, 22 nmol of 3-aminopropyltriethoxysilane (APTES) was added and stirred at room temperature for 5 h. After repeated rinsing and drying, amino-functionalized magnetic nanoparticles can be obtained.

[0026] Take the egg white of fresh eggs and phosphate buffer solution (20nmol) and dilute them at a volume ratio of 1:1, and then continuously stir the reaction in an ice-water bath for 6 hours. Insoluble...

Embodiment 3

[0029] 3gFeCl 2 4H 2 O and 8.1 g FeCl 3 ·6H 2 O was dissolved in 200mL of deionized water, at room temperature, under the protection of nitrogen, 85mL of 25% ammonia water was added dropwise to it, stirred for 30min, then heated to 70°C and continued to stir for 30min, cooled to room temperature, collected with a magnet, and washed with deionized water several times Rinse and dry to obtain magnetic Fe 3 o 4 Nanoparticles. 4g magnetic Fe 3 o 4 Nanoparticles were put into 50mL of anhydrous toluene, sonicated for 15min, under the protection of nitrogen, 22nmol 3-aminopropyltriethoxysilane (APTES) was added, stirred at room temperature for 5h, magnetic particles were collected with a magnet, and the magnetic particles were collected with ethanol and dichloromethane After repeated washing and drying, amino functionalized magnetic nanoparticles can be obtained.

[0030] Take the egg white of fresh eggs and phosphate buffer solution (20nmol) to dilute at a volume ratio of 1:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com