Solder and production method thereof

A production method and solder technology, applied in welding/cutting media/materials, welding media, welding equipment, etc., can solve the problem of affecting the stability and reliability of magnetrons, reduce the vacuum degree of vacuum tubes, and restrict the wide application of ruthenium-molybdenum solder and other problems, to achieve the effect of low saturated vapor pressure, easy access, and large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

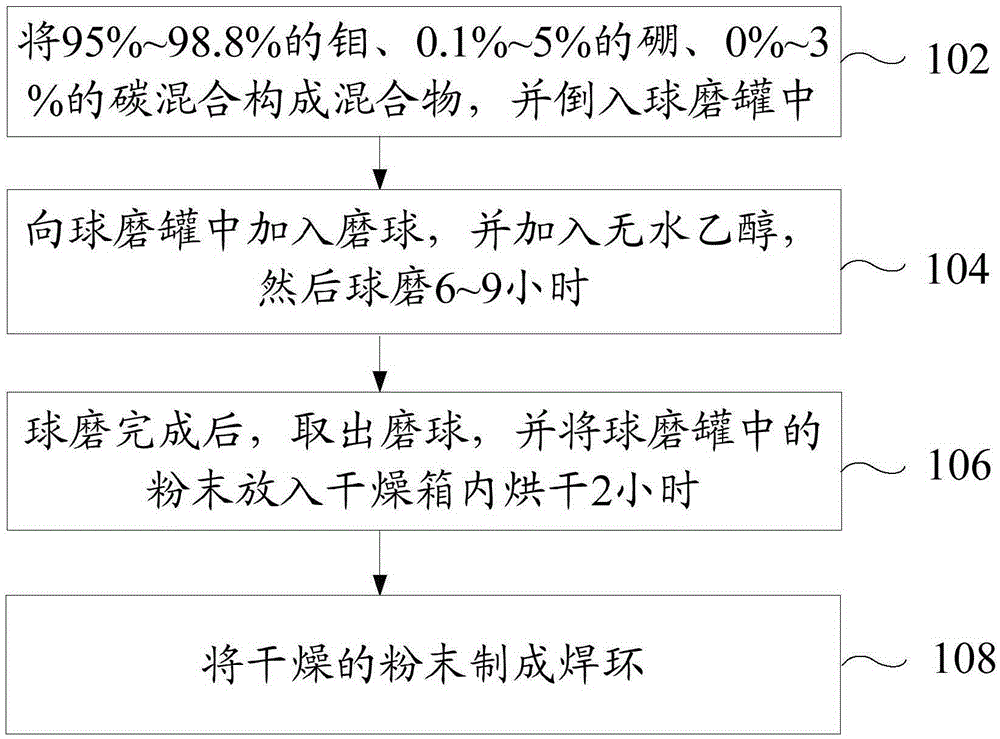

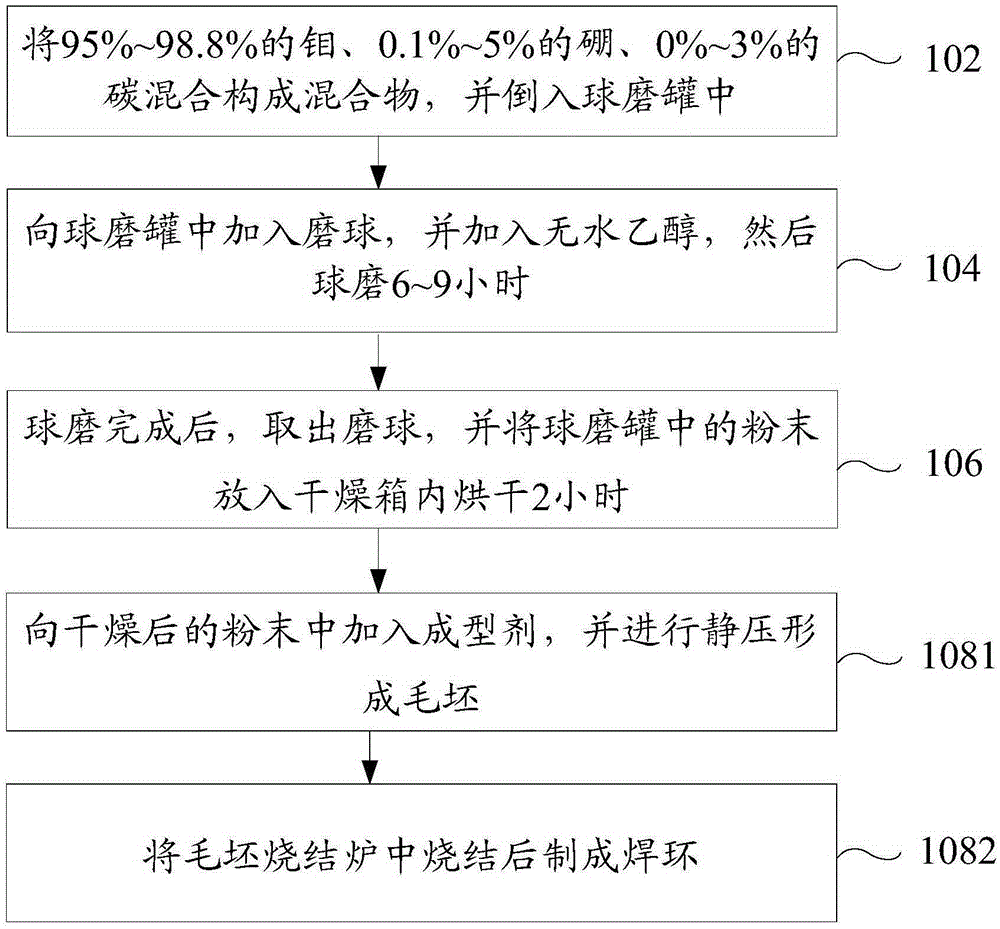

Method used

Image

Examples

Embodiment 1

[0066] According to the mass content ratio of the molybdenum powder and the boron powder being 96.5%: 3.5%, the molybdenum powder and the boron powder are weighed and poured into a ball mill jar. Add agate balls with different diameters according to the ratio of ball to material ratio of 4:1, and add absolute ethanol ball mill for 6 hours according to the ratio of solid to liquid ratio of 3:1. After the ball milling, the agate balls were taken out, and the remaining powder was dried in an oven at 60° C. for 2 hours. The dried powder is then added with a molding agent, formed into a blank by static pressure, and finally sintered in a hydrogen atmosphere sintering furnace at 1450-1500°C for 60-90 minutes to become a welding ring of a certain specification.

[0067] In this embodiment, molybdenum powder and boron powder are mixed according to a certain ratio, and a binary alloy is formed by ball milling. The melting point of the alloy is about 1950-2100°C. High, the solder produ...

Embodiment 2

[0069] According to the mass content ratio of the molybdenum powder, boron powder and carbon powder being 96.7%: 2.5%: 0.8%, the boron powder, carbon powder and molybdenum powder are weighed and poured into a ball mill jar. Add agate balls with different diameters according to the ratio of ball to material 6:1, and add absolute ethanol ball mill for 9 hours according to the ratio of solid to liquid 3:1. After the ball milling, the agate balls were taken out, and the remaining powder was dried in an oven at 60° C. for 2 hours. The dried powder is then added with a molding agent, formed into a blank by static pressure, and finally sintered in a hydrogen atmosphere sintering furnace at 1450-1500°C for 60-90 minutes to become a welding ring of a certain specification.

Embodiment 3

[0071] According to the mass content ratio of the molybdenum powder, boron powder and carbon powder being 97.5%: 2.0%: 0.5%, the boron powder, carbon powder and molybdenum powder are weighed and poured into a ball mill jar. Add agate balls with different diameters according to the ratio of ball to material 6:1, and add absolute ethanol ball mill for 9 hours according to the ratio of solid to liquid 3:1. After the ball milling, the agate balls were taken out, and the remaining powder was dried in an oven at 60° C. for 2 hours. The dried powder is then added with a molding agent, formed into a blank by static pressure, and finally sintered in a hydrogen atmosphere sintering furnace at 1450-1500°C for 60-90 minutes to become a welding ring of a certain specification.

[0072] In the above two embodiments, molybdenum powder, carbon powder and boron powder are mixed according to a certain ratio, and a ternary alloy is formed by ball milling. The melting point of the alloy is about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com