a kind of laalo <base:sub> 3</base:sub> Preparation method of doped composite ybco thin film

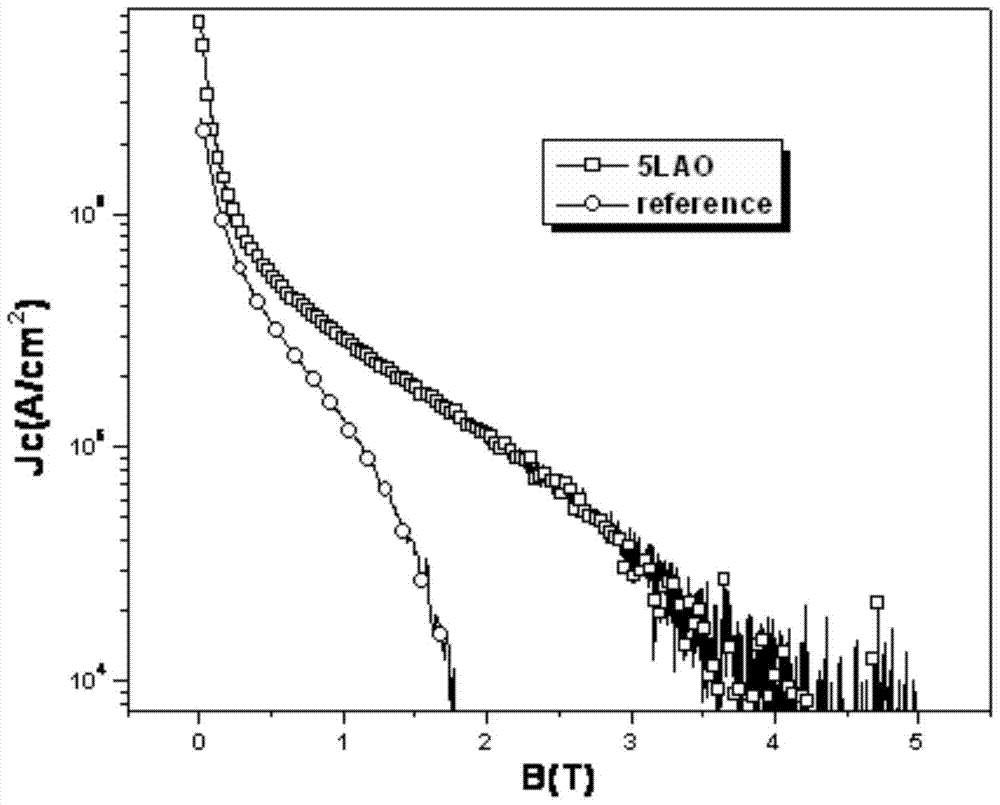

A technology of thin film and precursor liquid, which is applied in the field of composite thin film preparation, to achieve the effects of reducing damage, shortening the sintering process time and improving the current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Dissolve 0.127g of lanthanum acetylacetonate and 0.046g of aluminum acetylacetonate and 1.69g of yttrium acetate and 2.55g of barium acetate into deionized water according to the LAO doping amount of 5% (molar doping amount), and then add 4ml of trifluoroacetic anhydride, stirred at 50°C for 2h to obtain precursor solution A; dissolved 3g of copper acetate in deionized water, added 6ml of acrylic acid, stirred in 80°C water bath for 1h to obtain precursor solution B; mixed all A and B , distilled at 60°C; add anhydrous methanol after distilling the water, repeat the distillation 3 times, and finally use anhydrous methanol to set the volume to 20ml to obtain a composite YBCO solution with a molar doping amount of LAO of 5%.

[0026] 2) Coating the precursor solution onto the (001) LAO single crystal substrate by spin coating, the rotation speed is 6000rpm, and the time is 60s to obtain the precursor film;

[0027] 3) Under the condition of passing dry oxygen, the prec...

Embodiment 2

[0031] 1) According to the LAO doping amount is 7.5% content, 0.191g lanthanum acetylacetonate and 0.122g aluminum acetylacetonate and 1.69g yttrium acetate and 2.55g barium acetate are dissolved in deionized water, then add 4ml trifluoroacetic anhydride, in Stir at 50°C for 8 hours to obtain precursor solution A; dissolve 3g of copper acetate in deionized water, add 6ml of acrylic acid, stir in a water bath at 80°C for 3 hours to obtain precursor solution B; mix A and B completely, and distill at 60°C; After distilling off the water, add anhydrous methanol, repeat the distillation 3 times, and finally set the volume to 20ml with anhydrous methanol to obtain a composite YBCO solution with a molar doping amount of LAO of 7.5%.

[0032] 2) Coating the precursor solution onto the (001) LAO single crystal substrate by spin coating, the rotation speed is 4000rpm, and the time is 120s to obtain the precursor film;

[0033] 3) Under the condition of passing dry oxygen, the precursor ...

Embodiment 3

[0037] 1) According to the LAO doping amount is 2.5% content, 0.064g lanthanum acetylacetonate and 0.041g aluminum acetylacetonate and 1.69g yttrium acetate and 2.55g barium acetate are dissolved in deionized water, then add 4ml trifluoroacetic anhydride, in Stir at 50°C for 4 hours to obtain precursor solution A; dissolve 3g of copper acetate in deionized water, add 6ml of acrylic acid, stir in a water bath at 80°C for 2 hours to obtain precursor solution B; mix all A and B, and distill at 60°C; After distilling off the water, add anhydrous methanol, repeat the distillation 3 times, and finally set the volume to 20ml with anhydrous methanol to obtain a composite YBCO solution with a molar doping amount of LAO of 2.5%.

[0038] 2) Coating the precursor liquid onto the (001) LAO single crystal substrate by spin coating, the rotation speed is 5000rpm, and the time is 100s to obtain the precursor film;

[0039] 3) Under the condition of passing dry oxygen, the precursor film was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com