Special phalaenopsis amabilis controlled release fertilizer produced by utilizing waste agaricus bisporus bracts and preparation method

A technology of Agaricus bisporus waste mushroom bracts and Phalaenopsis, which is applied in the field of controlled-release fertilizers and slow-release, can solve the problems of affecting the output and quality of secondary fruiting, the rapid increase of the number and types of miscellaneous bacteria, and the pollution of agricultural ecological environment, etc., and achieve effective Conducive to water and fertilizer conservation, short processing time, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

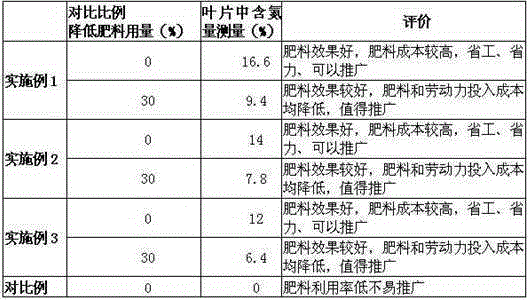

Embodiment 1

[0031] The preparation method of the Phalaenopsis special controlled-release fertilizer produced by using the spent mushroom buds of Agaricus bisporus comprises the steps of pulverizing, adjusting pH value, inoculating strains, sieving and fermenting. All aspects of the fermentation process are carried out in strict accordance with the implementation steps:

[0032] (1) Pulverization: put the harvested waste mushroom buds of Agaricus bisporus into a pulverizer, and pulverize the mixture. The parts by weight of each component are as follows (60kg per part):

[0033] Agaricus bisporus waste mushroom buds: 47 servings

[0034] Perlite: 9 parts

[0035] Coating agent (the coating agent used in this embodiment is a silica polymer): 9 parts

[0036] Water-retaining agent (the water-retaining agent used in this example is green algae): 1.66 parts

[0037] Sawdust: 13.8 parts

[0038] Slow-release fertilizer (the slow-release fertilizer used in this example is long-acting ammonium...

Embodiment 2

[0045] The preparation method of the Phalaenopsis special controlled-release fertilizer produced by using the spent mushroom buds of Agaricus bisporus comprises the steps of pulverizing, adjusting pH value, inoculating strains, sieving and fermenting. All aspects of the fermentation process are carried out in strict accordance with the implementation steps:

[0046] (1) Pulverization: put the harvested waste mushroom buds of Agaricus bisporus into a pulverizer, and pulverize the mixture. The parts by weight of each component are as follows (60kg per part):

[0047] Agaricus bisporus waste mushroom buds: 48 servings

[0048] Perlite: 10 parts

[0049] Coating agent (the coating agent used in this embodiment is a silica polymer): 10 parts

[0050] Water-retaining agent (the water-retaining agent used in this example is seaweed): 1.7 parts

[0051] Sawdust: 15 parts

[0052] Slow-release fertilizer (the slow-release fertilizer used in this example is long-acting urea): 6 parts ...

Embodiment 3

[0059] The preparation method of the Phalaenopsis special controlled-release fertilizer produced by using the spent mushroom buds of Agaricus bisporus comprises the steps of pulverizing, adjusting pH value, inoculating strains, sieving and fermenting. All aspects of the fermentation process are carried out in strict accordance with the implementation steps:

[0060] (1) Pulverization: put the harvested waste mushroom buds of Agaricus bisporus into a pulverizer, and pulverize the mixture. The parts by weight of each component are as follows (60kg per part):

[0061] Agaricus bisporus waste mushroom buds: 46 servings

[0062] Perlite: 8 parts

[0063] Coating agent (the coating agent used in this embodiment is a silica polymer): 8 parts

[0064] Water-retaining agent (the water-retaining agent used in this example is spirulina): 1.6 parts

[0065] Sawdust: 13 parts

[0066] Slow-release fertilizer (the slow-release fertilizer used in this example is long-acting urea): 4 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com