Preparation method for surface-modified polyacrylic acid microspheres

A polyacrylic acid microsphere and surface modification technology, which is applied in the field of polysulfide sealants, can solve the problems of affecting product performance, poor dispersion, easy agglomeration of acrylic microspheres, etc., and achieve stable product performance, reduce viscosity, and enhance mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

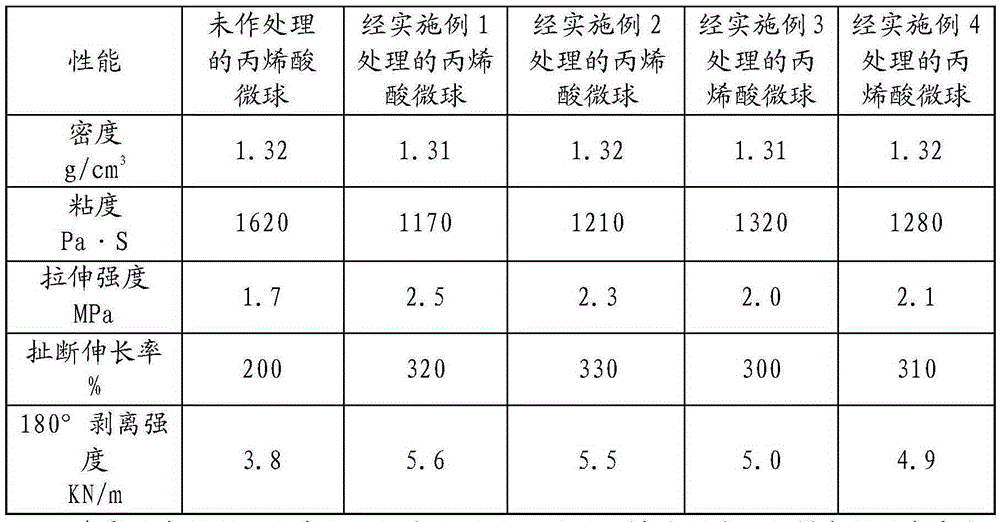

Examples

Embodiment 1

[0037] Weigh 100 g of dry polyacrylic acid microspheres and put them into the reaction kettle, and heat the reaction kettle to 60° C., start the stirring device, and stir at a low speed for about 10 minutes. Another 35g modifier 2-ethyl-7-hydroxyl-5-thiepine was weighed and placed in a burette, the stirring speed was adjusted to medium speed and the modifier was added dropwise to the reaction kettle, and the dropping rate was controlled to be about 18 drops / minute. After the dropwise addition, continue to stir at constant temperature for 3 hours, then remove the heating device, cool to room temperature, and keep stirring during the cooling process.

[0038] Weigh 30g of dimercaptoethyl sulfide and 700g of xylene and mix them thoroughly, add them to the stirring tank and stir and mix for 10min, and weigh 10g of pentamethyldiethylenetriamine, 5g of bicyclic imidazole and 100g of xylene, mix them fully and place them in a burette During the process, control the rate of addition...

Embodiment 2

[0040] Weigh 100 g of dry polyacrylic acid microspheres and put them into the reaction kettle, and heat the reaction kettle to 60° C., start the stirring device, and stir at a low speed for about 10 minutes. Another 45g modifier 9-hydroxy-7-thianonene was weighed and placed in a burette, the stirring speed was adjusted to medium speed and the modifier was added dropwise into the reaction kettle, and the dropping rate was controlled to be about 20 drops / min. After the dropwise addition, continue to stir at constant temperature for 3 hours, then remove the heating device, cool to room temperature, and keep stirring during the cooling process.

[0041] Weigh 30g of dimercaptoethyl sulfide, 400g of ethanol, and 350g of ethyl acetate, mix them thoroughly, add them into the stirring tank and stir and mix for 10min, and weigh 8g of 2,4,6-tris(dimethylaminomethyl)phenol, 7g of bicyclic Mix imidazole and 100g xylene thoroughly and put it in a burette, control the dropping rate to about...

Embodiment 3

[0044] Weigh 100 g of dry polyacrylic acid microspheres and put them into the reaction kettle, and heat the reaction kettle to 60° C., start the stirring device, and stir at a low speed for about 10 minutes. Another 45g modifier 2-chloro-7-hydroxyl-5-thiepine was weighed and placed in a burette, the stirring speed was adjusted to medium speed and the modifier was added dropwise to the reaction kettle, and the dropping rate was controlled to be about 20 drops / minute. After the dropwise addition, continue to stir at constant temperature for 3 hours, then remove the heating device, cool to room temperature, and keep stirring during the cooling process.

[0045]Weigh 30g of dimercaptoethyl sulfide, 400g of ethanol, and 350g of ethyl acetate, mix them thoroughly, add them into a stirring tank and stir and mix for 10min, and weigh 8g of 2,4,6-tris(dimethylaminomethyl)phenol, 3g of dimethicone Ethylamine and 100g of xylene were thoroughly mixed and placed in a burette, the rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com