Graphene/ polyvinyl alcohol nanofibers membrane adsorbent, preparation method and appliance

A technology of nanofiber membrane and polyvinyl alcohol, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of easy dispersion, increase of preparation cost, leakage of toxic and harmful substances, etc., and achieve specific surface area Larger, shorten the adsorption equilibrium time, and the effect of environmental protection in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

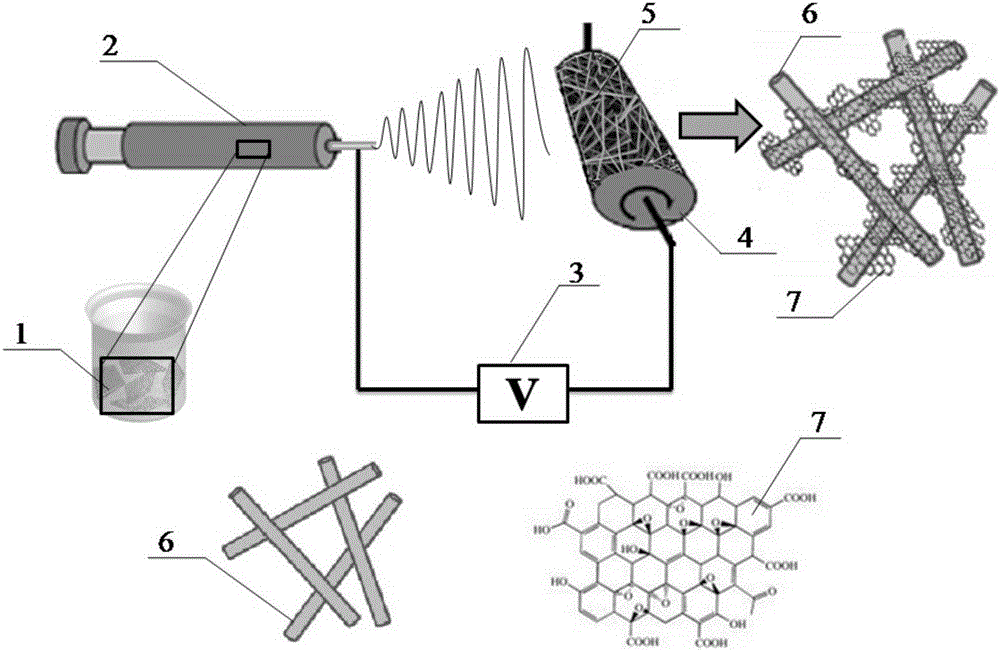

[0026] A preparation method of electrospinning nanofiber membrane that adsorbs heavy metal ions includes the following operation steps:

[0027] (1) Add 12 mg of graphene oxide to 5 g of deionized water, and after ultrasonic treatment for 0.5 h, a uniformly dispersed graphene oxide solution is obtained;

[0028] (2) Add 1.2 g of polyvinyl alcohol to 10 g of deionized water, heat the solution to 88° C., dissolve for 3 hours, and cool to room temperature to obtain a polyvinyl alcohol solution;

[0029] (3) The graphene oxide aqueous solution and the polyvinyl alcohol solution are mixed, and then stirred for 0.5 h at a stirring speed of 100 revolutions / min to obtain a spinning solution of graphene oxide and polyvinyl alcohol. The spinning solution contains polyethylene The mass fraction of alcohol is 8wt%;

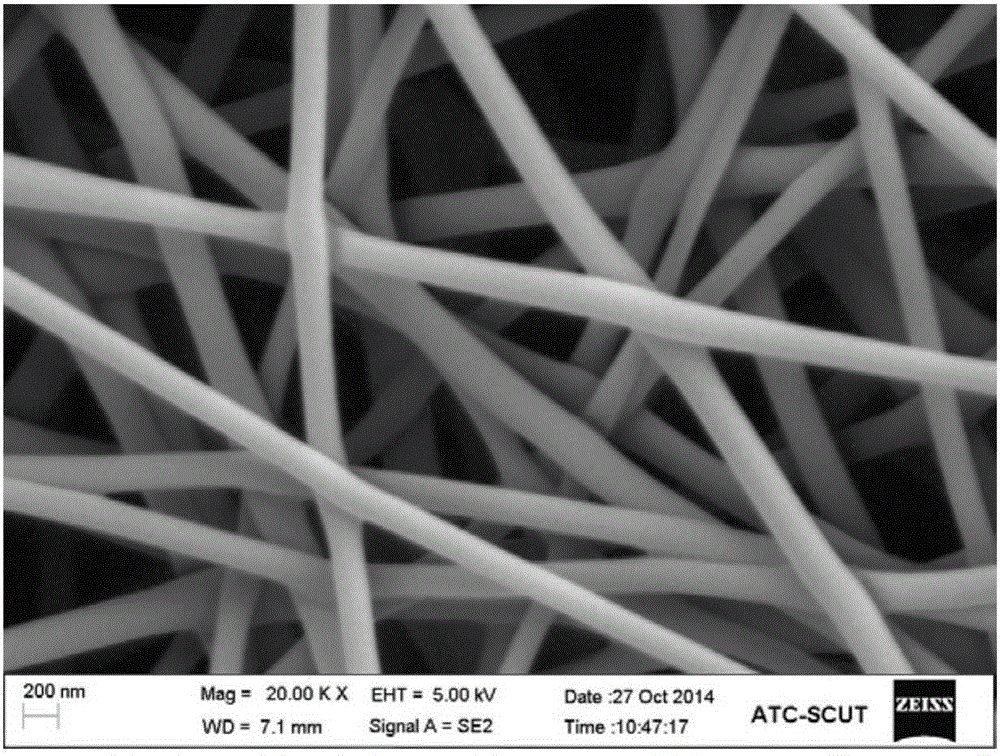

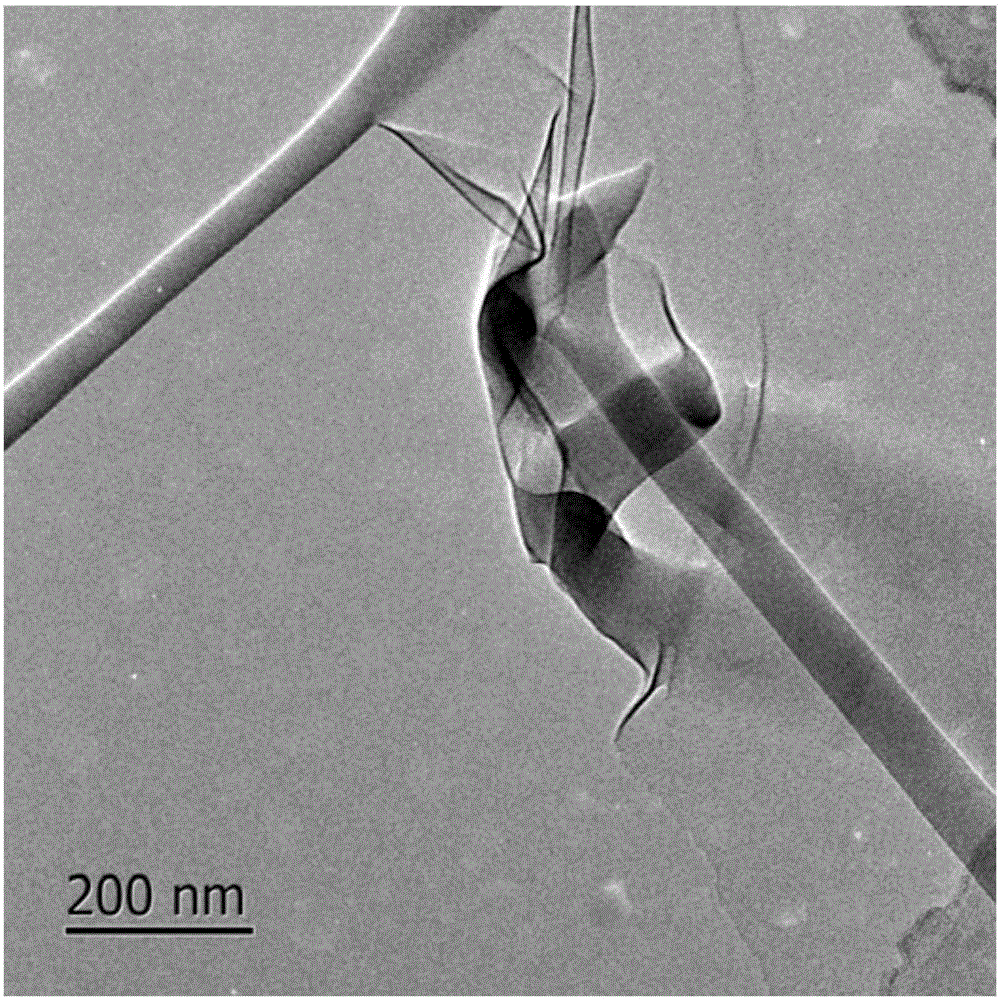

[0030] (4) The above-mentioned spinning stock solution is added to the electrospinning equipment for spinning to obtain graphene oxide and polyvinyl alcohol nanofiber membrane. Elect...

Embodiment 2

[0035] A preparation method of electrospinning nanofiber membrane that adsorbs heavy metal ions includes the following operation steps:

[0036] (1) Adding 84 mg of graphene oxide to 5 g of deionized water, and ultrasonic treatment for 1 hour to obtain a uniformly dispersed graphene oxide solution;

[0037] (2) Add 1.2 g of polyvinyl alcohol to 10 g of deionized water, heat the solution to 92°C, dissolve for 3 hours, and cool to room temperature to obtain a polyvinyl alcohol solution;

[0038] (3) Mix the graphene oxide aqueous solution and the polyvinyl alcohol solution, and then stir for 3 hours at a stirring speed of 150 revolutions / min to obtain a spinning solution of graphene oxide and polyvinyl alcohol. The spinning solution contains polyvinyl alcohol. The mass fraction of is 8wt%;

[0039] (4) The above-mentioned spinning stock solution is added to the electrospinning equipment for spinning to obtain graphene oxide and polyvinyl alcohol nanofiber membrane. The electrospinning c...

Embodiment 3

[0044] A preparation method of electrospinning nanofiber membrane that adsorbs heavy metal ions includes the following operation steps:

[0045] (1) Add 120 mg of graphene oxide to 5 g of deionized water, and after ultrasonic treatment for 3 hours, obtain a uniformly dispersed graphene oxide solution;

[0046] (2) Add 1.2 g of polyvinyl alcohol to 10 g of deionized water, heat the solution to 95° C., dissolve for 3.5 hours, and cool to room temperature to obtain a polyvinyl alcohol solution;

[0047] (3) Mix the graphene oxide aqueous solution and the polyvinyl alcohol solution, and then stir for 5 hours at a stirring speed of 250 revolutions / min to obtain a spinning solution of graphene oxide and polyvinyl alcohol. The spinning solution contains polyvinyl alcohol. The mass fraction of is 8wt%;

[0048] (4) The above-mentioned spinning stock solution is added to the electrospinning equipment for spinning to obtain graphene oxide and polyvinyl alcohol nanofiber membrane. The electrospi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com