Preparation method of bismuth oxychloride composite magnetic photocatalyst

A composite magnetic and photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of narrow band gap, difficult recycling and low photocatalytic efficiency of bismuth oxychloride composite magnetic photocatalyst and other problems, to achieve the effect of low cost, simple operation and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of bismuth oxychloride composite magnetic photocatalyst, concrete steps are as follows:

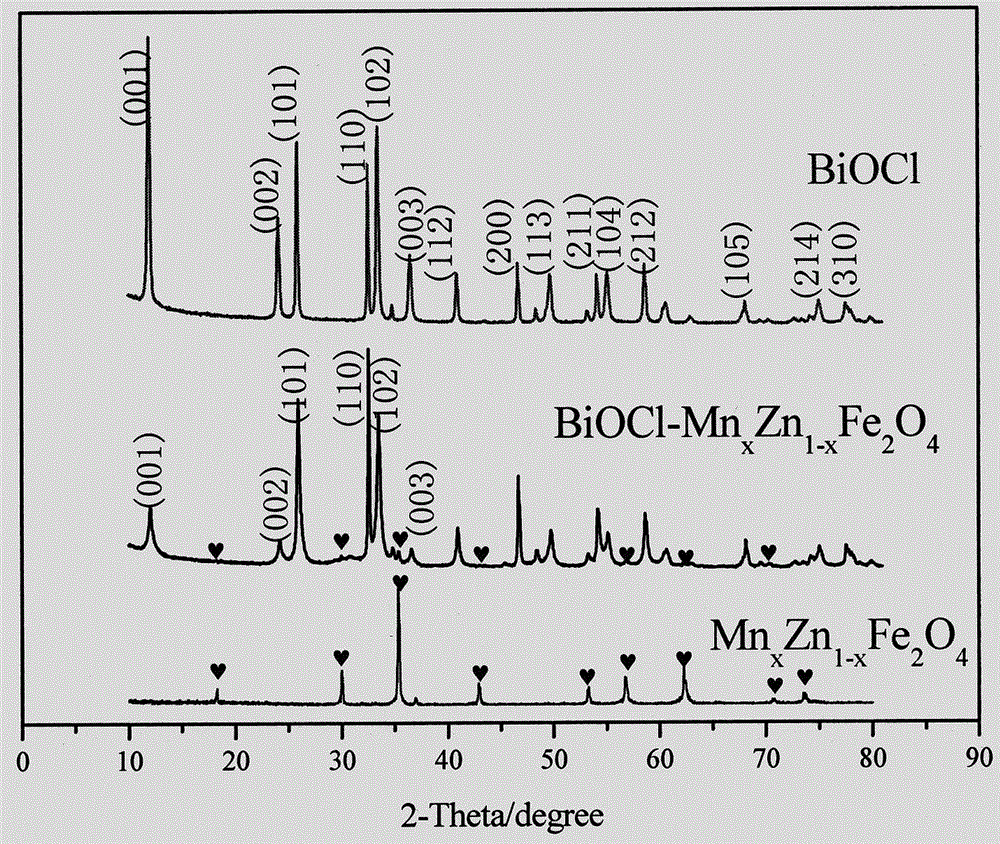

[0026] (1) Preparation of manganese zinc ferrite

[0027] Take by weighing 1.91g zinc sulfate, 2.77g manganese sulfate, 14.57g ferric chloride hexahydrate, add water and dissolve to obtain solution, then add zinc sulfate solution and ferric chloride solution in manganese sulfate solution, fully stir to obtain mixed solution; weigh 16.40g g ammonium oxalate was dissolved in water to obtain ammonium oxalate solution. The mixed solution and the ammonium oxalate solution were heated to 80° C. under water bath conditions, and then the mixed solution was slowly added dropwise to the ammonium oxalate solution, and the pH value was adjusted to 7 with ammonia water. Aging the obtained oxalate precipitate at room temperature for 12 hours, filtering, washing and drying, and finally placing it in a muffle furnace and roasting at 1200°C for 3 hours to obtain mangan...

Embodiment 2

[0033] A kind of preparation method of bismuth oxychloride composite magnetic photocatalyst, concrete steps are as follows:

[0034] (1) with embodiment 1;

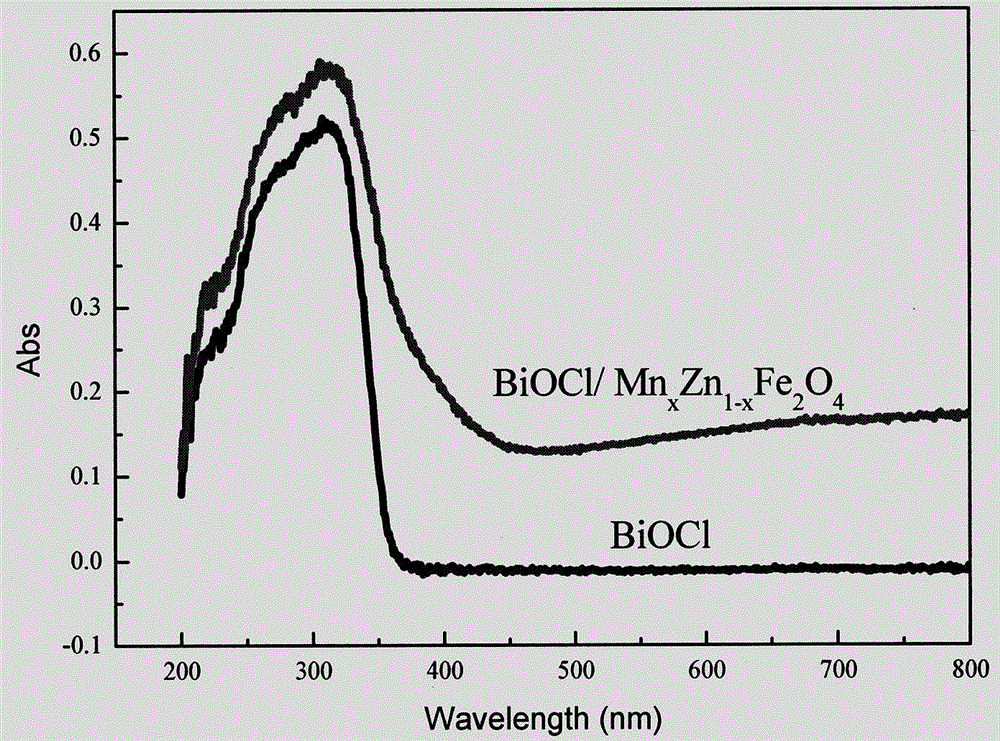

[0035] (2) Weigh 4.85g of bismuth nitrate pentahydrate and add it to 20mL of dilute nitric acid (concentration: 4mol / L), and magnetically stir for 30min to obtain a transparent solution A. The mass ratio of manganese zinc ferrite and bismuth oxychloride is 15:100 Weigh an appropriate amount of manganese zinc ferrite, 0.58g of sodium chloride and 0.05g of sodium dodecylbenzene sulfonate, add them to 120ml of water, stir mechanically for 30min to obtain solution B, slowly add solution A dropwise into solution B and stir 30min, adjust the pH to 2.5 with sodium hydroxide solution (concentration: 2mol / L), heat in a water bath at 80°C and mechanically stir for 2h to obtain the precursor of the gray composite magnetic photocatalyst;

[0036] (3) The composite magnetic photocatalyst precursor was washed with distilled water and ...

Embodiment 3

[0038] A kind of preparation method of bismuth oxychloride composite magnetic photocatalyst, concrete steps are as follows:

[0039] (1) with embodiment 1;

[0040] (2) Weigh 4.85g of bismuth nitrate pentahydrate and add it to 20mL of dilute nitric acid (concentration: 4mol / L), and stir magnetically for 30min to obtain a transparent solution A. The mass ratio of manganese zinc ferrite and bismuth oxychloride is 17:100 Weigh an appropriate amount of manganese zinc ferrite, 0.58g of sodium chloride and 0.05g of sodium dodecylbenzene sulfonate, add them to 120ml of water, stir mechanically for 30min to obtain solution B, slowly add solution A dropwise into solution B and stir For 30 minutes, adjust the pH to 2 with sodium hydroxide solution (concentration: 2mol / L), heat in a water bath at 80°C and mechanically stir for 4 hours to obtain the precursor of the gray composite magnetic photocatalyst;

[0041] (3) The composite magnetic photocatalyst precursor was washed with distille...

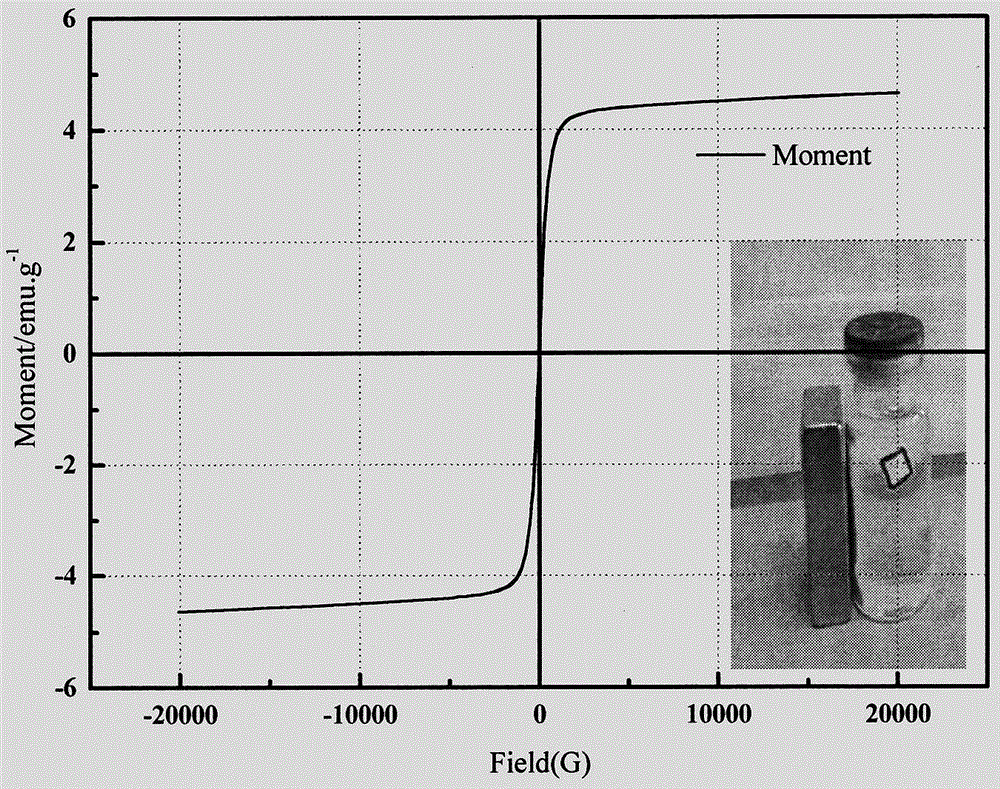

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com