Method for preparing dilute nitric acid, sponge tin and polymeric aluminum through spent tin-fading liquid

A technology of polyaluminum chloride and dilute nitric acid, applied in aluminum chloride, nitric acid, aluminum halide and other directions, can solve the problems of not realizing resource utilization, poor separation efficiency, difficult operation, etc., and achieve easy processing, mild process reaction, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

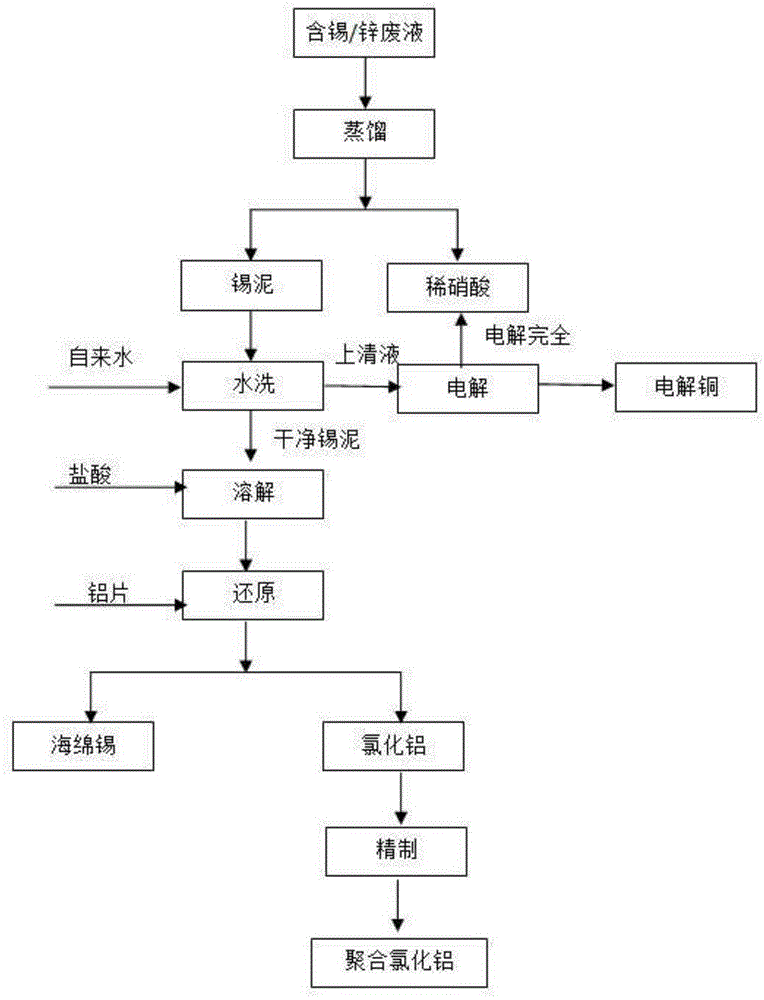

Image

Examples

Embodiment 1

[0034] Take 1000mL of waste tin stripping solution from the production line of a PCB manufacturer, heat the waste tin stripping solution to 75°C through a steam spacer, and circulate the feed under a vacuum of -0.05MPa for vacuum distillation to obtain 800mL of dilute nitric acid and 200mL of tin sludge; After separating the obtained 200mL tin sludge, add 200mL water to it and stir for 15 minutes, heat up to 50°C, add water to adjust the acidity to 35%, add 16mL of 0.05wt% flocculant solution, and stir for 1 hour. Set aside for 15 minutes to recover the supernatant and the lower layer of tin sludge; collect the recovered tin sludge and wash it twice to obtain the lower layer of tin sludge A; then mix all the supernatants to obtain supernatant B; Solution B is placed in a self-made electrolytic cell, and copper is recovered by electrolysis. After the copper is extracted, the electrolytic tail liquid can be used as dilute nitric acid product through concentration and enrichment; ...

Embodiment 2

[0036]Take 1000mL of waste tin stripping solution from the production line of a PCB manufacturer, heat the waste tin stripping solution to 80°C through a steam spacer, and circulate the feed under a vacuum of -0.04MPa for vacuum distillation to obtain 800mL of dilute nitric acid and 200mL of tin sludge; After separating the obtained 200mL tin sludge, add 300mL water therein and stir for 30 minutes, raise the temperature to 65°C, add water to adjust the acidity to 40%, add 0.1wt% flocculant solution 20mL, and stir for 1.5 hours, after the stirring is finished, stand still Set aside for 20 minutes to recover the supernatant and the lower layer of tin sludge; collect the recovered tin sludge and repeat the cleaning 3 times to obtain the lower layer of tin sludge A; then mix all the supernatants to obtain supernatant B; Solution B is placed in a self-made electrolytic cell, and copper is recovered by electrolysis. After the copper is extracted, the electrolytic tail liquid can be u...

Embodiment 3

[0038] Take 1000mL of waste tin stripping solution from the production line of a PCB manufacturer, heat the waste tin stripping solution to 85 degrees through a steam spacer, and circulate the feed under a vacuum of -0.03MPa for vacuum distillation to obtain 800mL of dilute nitric acid and 200mL of tin sludge; After separating the obtained 200mL tin sludge, add 400mL water therein and stir for 60 minutes, raise the temperature to 80°C, add water to adjust the acidity to 50%, add 22mL of 0.15wt% flocculant solution, and stir for 2 hours, after the stirring ends, stand still Set aside for 30 minutes to reclaim the supernatant and the lower layer of tin sludge; collect the recovered tin sludge and repeat the cleaning 4 times to obtain the lower layer of tin sludge A; then mix all the supernatants to obtain supernatant B; Solution B is placed in a self-made electrolytic cell, and copper is recovered by electrolysis. After the copper is extracted, the electrolytic tail liquid can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com