Preparation method of aniline through catalytic nitrobenzene hydrogenation

A technology for the preparation of nitrobenzene and hydrogen, which is applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of harsh synthesis conditions, long reaction time and high reaction temperature, and achieves a simple and repeatable preparation process. Good usability and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

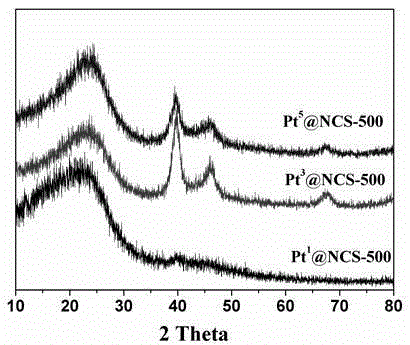

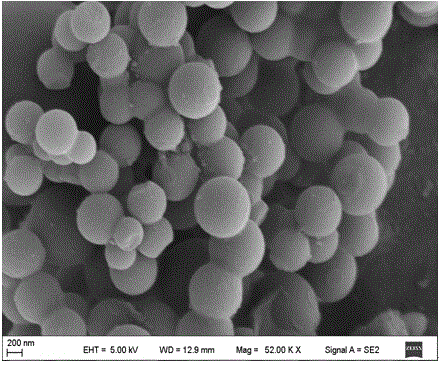

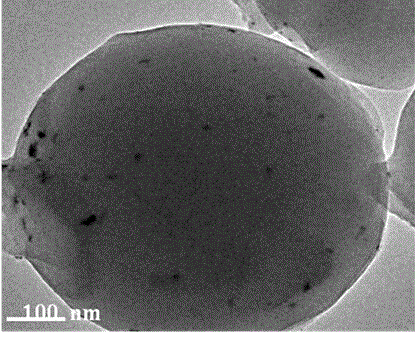

[0029] (1) Catalyst Pt 1 N 1 C 1 Preparation of S-600

[0030] Glucose (8.0g) was added to 80mL deionized water, stirred until the solution was clear, put into a 100mL reaction kettle lined with polytetrafluoroethylene, treated in an oven at 180°C for 12h, cooled to room temperature, and the product was centrifuged and washed several times. times, dried and ground to obtain carbon material C 1 S;

[0031] The obtained carbon material C 1 S (2.0g) and melamine (0.5g) were added to a 100mL round-bottomed flask, and 80mL of ethanol was added to it, and stirred vigorously at 80°C until the solvent was completely evaporated; then the mixture was placed in a tube furnace, and the N 2 Under protection, calcine at 600°C for 1 h; wait until the system drops to room temperature, and grind to obtain nitrogen-functionalized carbon materials, denoted as N 1 C 1 S-600;

[0032] The prepared nitrogen functionalized carbon material N 1 C 1 S-600 (0.5g) is ultrasonically dispersed i...

Embodiment 2

[0036] (1) Catalyst Pt 1 N 1 C 2 Preparation of S-600

[0037] Add sucrose (8.0g) into 80mL deionized water, stir until a clear solution, put it into a 100mL reaction kettle lined with polytetrafluoroethylene, and treat it in an oven at 180°C for 12h; cool to room temperature, centrifuge and wash the product After several times, dry and grind to obtain carbon material C 2 S;

[0038] The obtained carbon material C 2 S (2.0g) and melamine (0.5g) were added to a 100mL round-bottomed flask, and 80mL of ethanol was added to it, and stirred vigorously at 80°C until the solvent was completely evaporated; the mixture was placed in a tube furnace and heated under N 2 Under protection, calcined at 600°C for 1 h; when the system dropped to room temperature, it was ground to obtain the nitrogen-functionalized carbon material N 1 C 2 S-600;

[0039] Nitrogen functionalized carbon material N 1 C 2 S-600 (0.5g) is ultrasonically dispersed in ethanol, add 1.34mL0.0193mol / L chloropl...

Embodiment 3

[0043] (1) Catalyst Pt 1 N 2 C 1 Preparation of S-600: Glucose (8.0g) was added to 80mL deionized water, stirred until the solution was clear, put into a 100mL reaction kettle lined with polytetrafluoroethylene, treated in an oven at 180°C for 12h, cooled to room temperature, The product is centrifuged, washed several times, dried, and ground to obtain carbon material C 1 S;

[0044] The obtained carbon material C 1 S (2.0g) and N,N-dimethylethanolamine (0.5g) were added to a 100mL round bottom flask, and 80mL of ethanol was added to it, and stirred vigorously at 80°C until the solvent was completely evaporated; then the mixture was placed into the tube furnace at N 2 Under protection, calcined at 600°C for 1 h; when the system dropped to room temperature, it was ground to obtain the nitrogen-functionalized carbon material N 2 C 1 S-600;

[0045] Nitrogen functionalized carbon material N 2 C 1 S-600 (0.5g) is ultrasonically dispersed in ethanol, add 1.34mL0.0193mol / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com