Preparation method of high-flexibility amphoteric ionic hydrogel

A zwitterionic and hydrogel technology, applied in the field of highly flexible zwitterionic hydrogel, can solve the problems of not being widely used, poor mechanical properties, complicated methods, etc., and achieve easy promotion, good flexibility, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

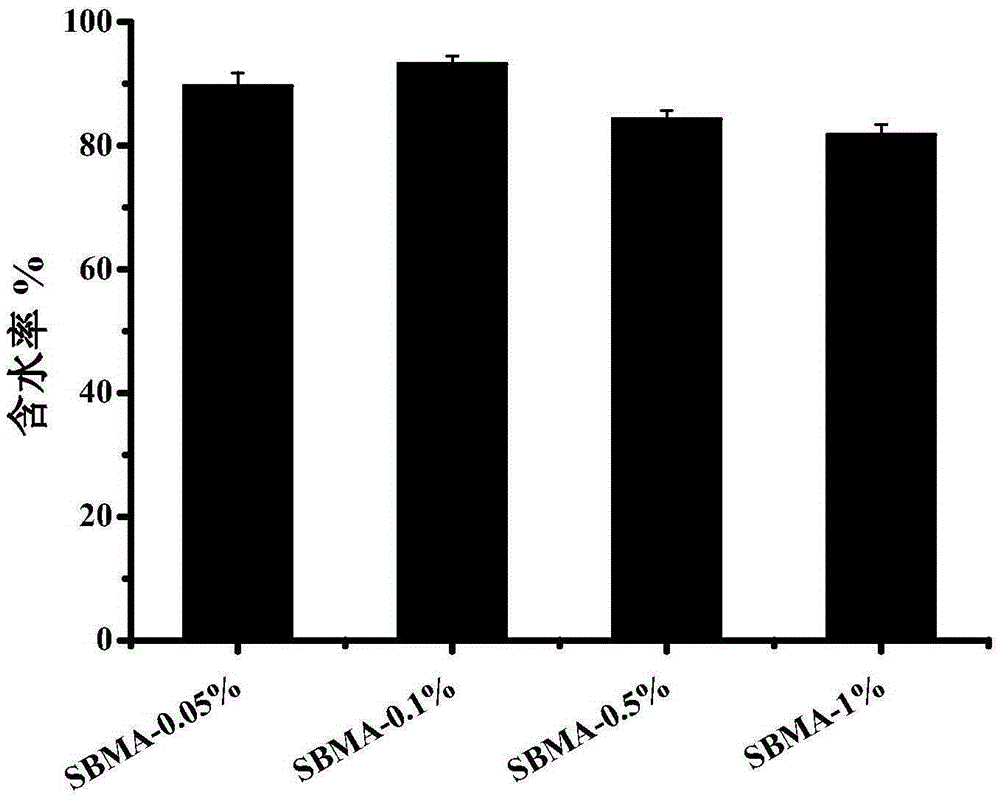

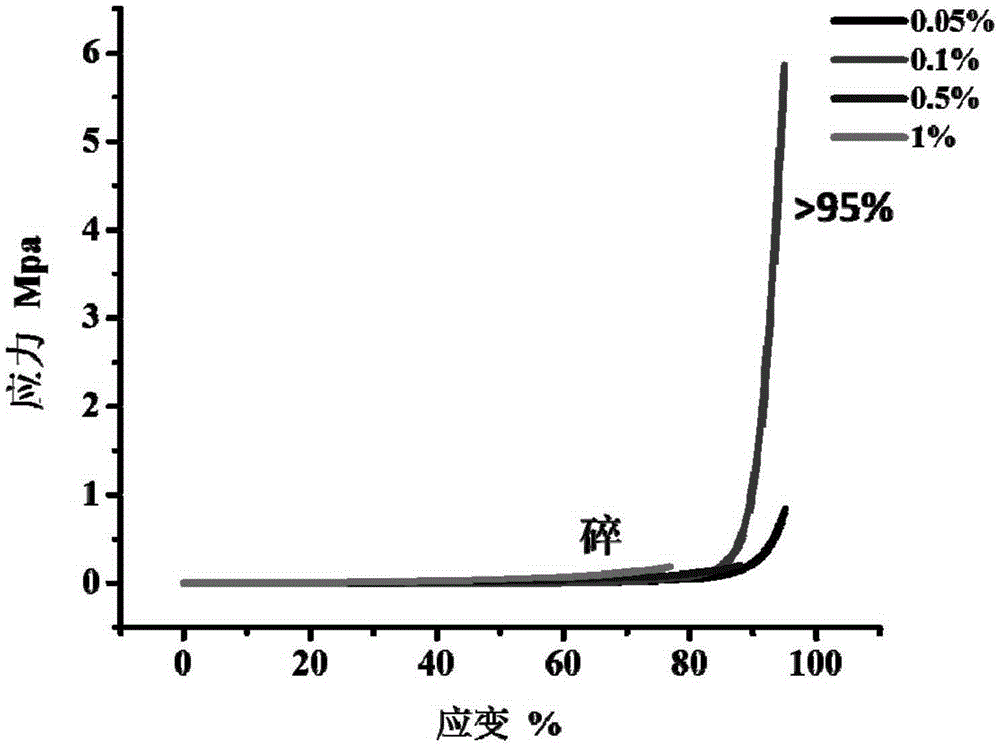

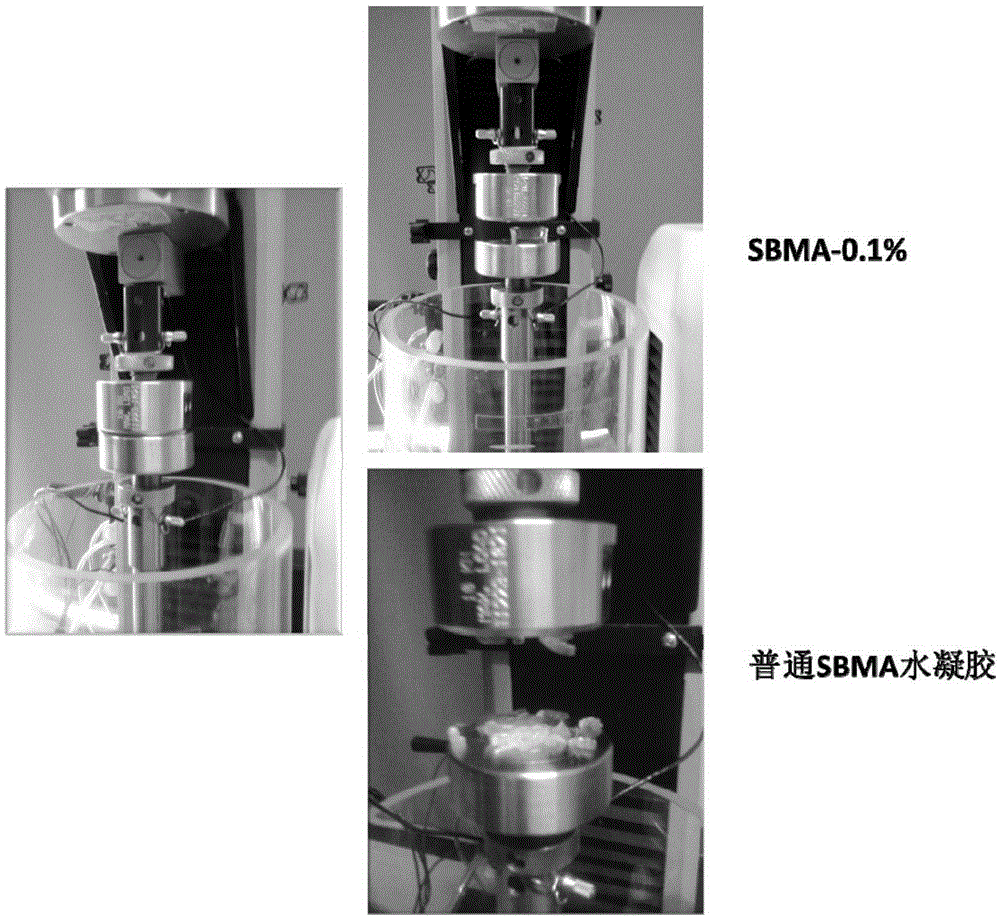

[0017] Example 1: At room temperature (preferably 25°C), the monomer [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfopropyl)ammonium hydroxide (SBMA) 1.4g Add 0.0014g of polyethylene glycol dimethacrylate (PEGDMA, molecular weight 550, 0.1% relative to the mass ratio of monomer SBMA) into a 5ml centrifuge tube, and dissolve the monomer and crosslinker with 1ml of deionized water Finally, add 0.014g of photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenone (Irgacure2959, the quality of the initiator is 1% of the monomer) and wrap it with tin foil to avoid light deal with. The mixed solution containing monomer, crosslinking agent and initiator was injected into the sealed mold, and the mold was irradiated in a UV curing light box (RSV-2000, Tianjin Ruisent Ultraviolet Equipment Co., Ltd.) for 10 minutes to fully initiate free radical polymerization. Then the mold was repeatedly rinsed with deionized water several times. For the first three days, the water was changed ev...

example 2

[0018] Example 2: At room temperature (preferably 25°C), the monomer [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfopropyl)ammonium hydroxide (SBMA) 1.4g Add cross-linking agent polyethylene glycol dimethacrylate 0.0007 (PEGDMA, molecular weight 330, relative monomer mass ratio 0.05%, sigma) into a 5ml centrifuge tube, dissolve monomer and cross-linking agent with 1ml deionized water Finally, 0.014 g of photoinitiator 2-hydroxyl-4'-(2-hydroxyethoxyl)-2-methylpropiophenone was added, wrapped with tin foil and protected from light. The mixed solution containing monomer, crosslinking agent and initiator was injected into the sealed mold, and the mold was irradiated for 30 minutes in a UV curing light box (RSV-2000 from Tianjin Ruisent Ultraviolet Equipment Co., Ltd.) to fully initiate free radical polymerization. Then the mold was repeatedly rinsed with deionized water several times. For the first three days, the water was changed every 3-5 hours, soaked for 8 days, and the above dei...

example 3

[0019] Example 3: At room temperature (preferably 25°C), the monomer [2-(methacryloyloxy)ethyl]dimethyl-(3-sulfopropyl)ammonium hydroxide (SBMA) (1.4 g, sigma company) and cross-linking agent polyethylene glycol dimethacrylate 0.007g (PEGDMA, molecular weight 2000, relative monomer mass ratio 0.5%, sigma) were added to a 5ml centrifuge tube and dissolved in 1ml deionized water After monomer and linking agent, add photoinitiator 2-hydroxyl-4 '-(2-hydroxyethoxy)-2-methyl propiophenone 0.014g (Irgacure2959, sigma, the quality of initiator is the monomer quality 1%) wrapped in tin foil to avoid light. The mixed solution containing monomer, crosslinking agent and initiator was injected into the sealed mold, and the mold was irradiated for 30 minutes in a UV curing light box (RSV-2000 from Tianjin Ruisent Ultraviolet Equipment Co., Ltd.) to fully initiate free radical polymerization. Then the mold was repeatedly rinsed with deionized water several times. For the first three days, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com