A kind of graphene 3D printing wire rod and preparation method thereof

A 3D printing and graphene technology, applied in the field of graphene 3D printing wire and its preparation, can solve problems such as low strength, high surface energy, and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

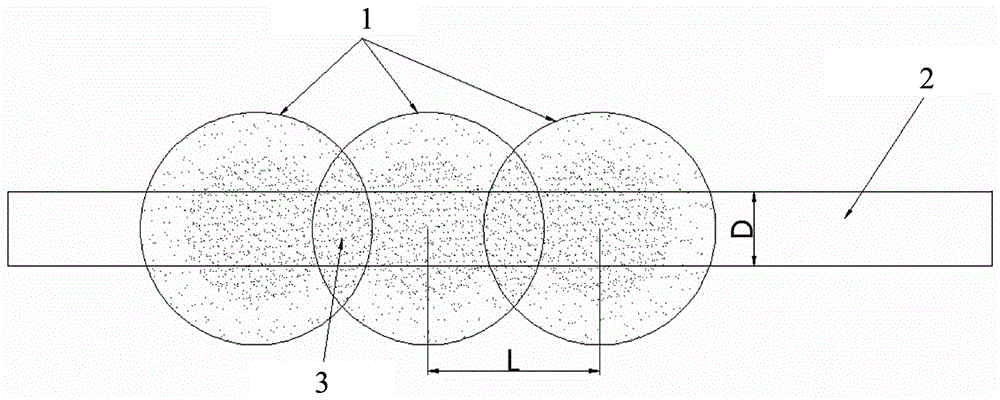

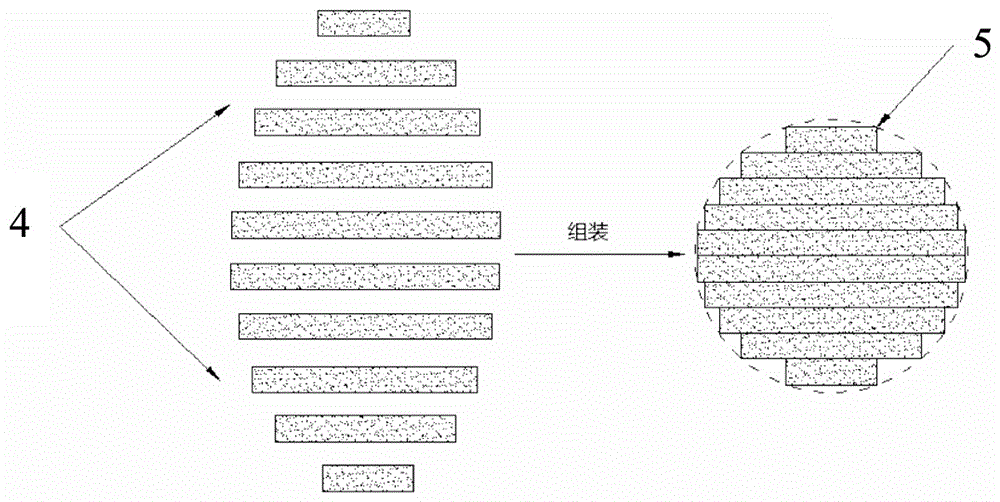

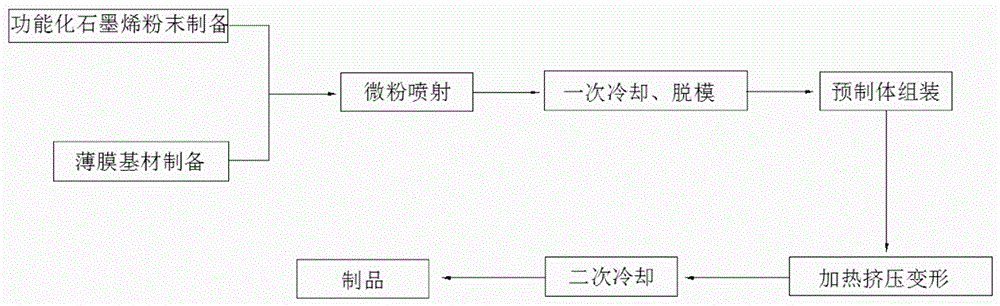

Method used

Image

Examples

Embodiment 1

[0046] (1) Preparation of functionalized graphene

[0047] Prepare functionalized graphene powder, the mass fraction of the functionalized graphene powder is composed of coupling agent: graphene=0.01;

[0048] The above-mentioned coupling agent is a γ-aminotriethoxysilane coupling agent.

[0049] Mix high-magnification expanded graphite powder, coupling agent and solvent in a beaker, put it into a magnetic stirrer, stir at a speed of 120r / min, and stir for 30min, and mix all materials evenly; then put it into a 180w, 40khz ultrasonic cleaner , ultrasonication for 6 hours in a water bath at 70°C; finally, the resulting mixture was dried and ground to obtain functionalized graphene powder;

[0050] In terms of mass, the above-mentioned high-magnification expanded graphite is 5 parts, the coupling agent is 0.05 parts, and the solvent is 94.95 parts. Among them, the magnification of expanded graphite is 900-1000.

[0051] Above-mentioned solvent is the mixture of water and etha...

Embodiment 2

[0079] (1) Preparation of functionalized graphene

[0080] Prepare functionalized graphene powder, the mass fraction of the functionalized graphene powder is composed of coupling agent: graphene=0.015;

[0081] The above-mentioned coupling agent is a γ-aminotriethoxysilane coupling agent.

[0082] Mix high-magnification expanded graphite powder, coupling agent and solvent in a beaker, put it into a magnetic stirrer, stir at a speed of 120r / min, and stir for 30min, and mix all materials evenly; then put it into a 180w, 40khz ultrasonic cleaner , ultrasonication for 6 hours in a water bath at 70°C; finally, the resulting mixture was dried and ground to obtain functionalized graphene powder;

[0083] In terms of mass, the above-mentioned high-magnification expanded graphite is 8 parts, the coupling agent is 0.12 parts, and the solvent is 91.88 parts. Among them, the magnification of expanded graphite is 900-1000.

[0084] Above-mentioned solvent is the mixture of water and eth...

Embodiment 3

[0112] (1) Preparation of functionalized graphene

[0113] Prepare functionalized graphene powder, the mass fraction of the functionalized graphene powder is composed of coupling agent: graphene=0.02;

[0114] The above-mentioned coupling agent is a γ-aminotriethoxysilane coupling agent.

[0115] Mix high-magnification expanded graphite powder, coupling agent and solvent in a beaker, put it into a magnetic stirrer, stir at a speed of 140r / min, and stir for 30min, and mix all materials evenly; then put it into a 180w, 40khz ultrasonic cleaner , ultrasonication for 7 hours in a water bath at 70°C; finally, the resulting mixture was dried and ground to obtain functionalized graphene powder;

[0116] In terms of mass, the above-mentioned high-magnification expanded graphite is 10 parts, the coupling agent is 0.2 parts, and the solvent is 8.98 parts. Among them, the magnification of expanded graphite is 900-1000.

[0117] Above-mentioned solvent is the mixture of water and ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com