A kind of high corrosion resistance anticorrosion paint and preparation method thereof

An anti-corrosion coating and high corrosion resistance technology, applied in the field of coatings, can solve the problems of complex preparation method and poor coating performance, and achieve the effects of simple preparation method, improved anti-corrosion, and improved corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

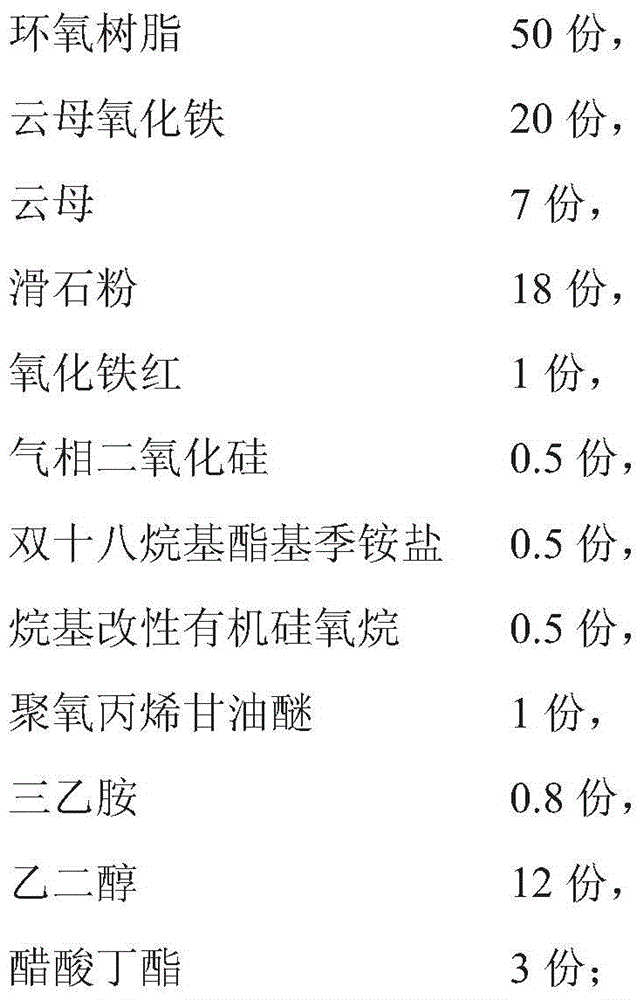

[0027] A high-corrosion-resistant anticorrosion coating, comprising the following components in parts by mass:

[0028]

[0029] Among them, the number average molecular weight of the epoxy resin is 550-900, and the particle size of the fumed silica is 7-20nm;

[0030] According to the proportioning of above-mentioned anticorrosion coating, make following preparation:

[0031] (1) Weigh epoxy resin, micaceous iron oxide, mica, talcum powder, iron oxide red, fumed silica and dioctadecyl ester quaternary ammonium salt according to the proportion, mix well, and grind at 90-140°C 1.5-3 hours to obtain a modified abrasive slurry; ultrasonic treatment is performed on the modified abrasive slurry, the ultrasonic treatment time is 18-25min, and the ultrasonic treatment temperature is 55-65°C;

[0032] (2) Weigh alkyl-modified organosiloxane, polyoxypropylene glyceryl ether, ethylene glycol and butyl acetate, mix well, and wait until the modified grinding slurry prepared in step (1...

Embodiment 2

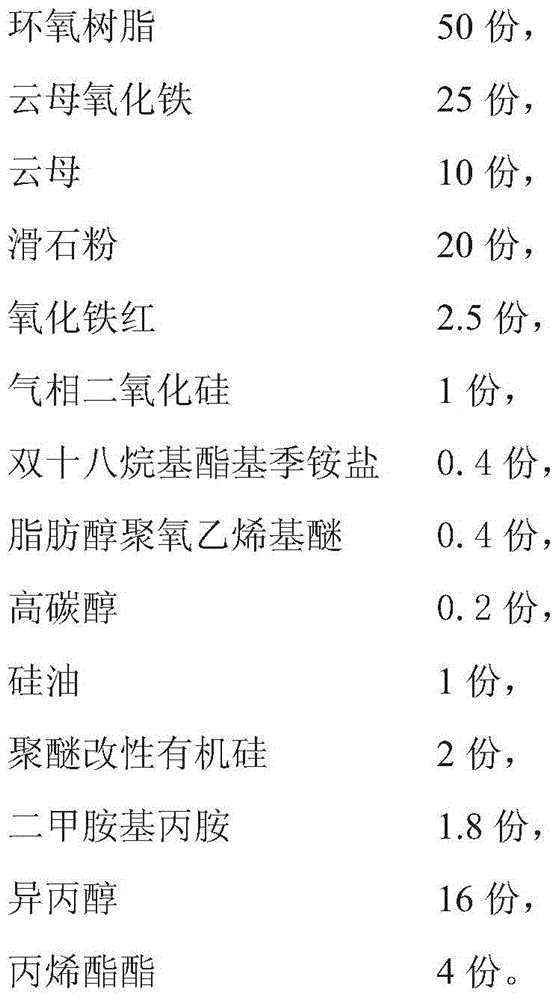

[0036] A high-corrosion-resistant anticorrosion coating, comprising the following components in parts by mass:

[0037]

[0038]

[0039] Among them, the number average molecular weight of the epoxy resin is 550-900, and the particle size of the fumed silica is 7-20nm;

[0040] According to the proportioning of above-mentioned anticorrosion coating, make following preparation:

[0041] (1) Weigh epoxy resin, mica iron oxide, mica, talcum powder, iron oxide red, fumed silica, dioctadecyl ester quaternary ammonium salt, fatty alcohol polyoxyethylene ether and high carbon Alcohol, after mixing evenly, grind at room temperature for 1.5-3 hours to obtain a modified abrasive slurry; perform ultrasonic treatment on the modified abrasive slurry, the ultrasonic treatment time is 18-25min, and the ultrasonic treatment temperature is 55-65°C;

[0042] (2) Weigh silicone oil, polyether modified silicone, isopropanol and acrylate, mix them evenly, and after the modified grinding slu...

Embodiment 3

[0046] A high-corrosion-resistant anticorrosion coating, comprising the following components in parts by mass:

[0047]

[0048]

[0049] Among them, the number average molecular weight of the epoxy resin is 550-900, and the particle size of the fumed silica is 7-20nm;

[0050]According to the proportioning of above-mentioned anticorrosion coating, make following preparation:

[0051] (1) Weigh epoxy resin, micaceous iron oxide, mica, talcum powder, iron oxide red, fumed silica, dioctadecyl ester quaternary ammonium salt and fatty alcohol polyoxyethylene ether according to the proportion, mix well Finally, grind at 90-140°C for 1.5-3 hours to obtain a modified abrasive slurry; perform ultrasonic treatment on the modified abrasive slurry, the ultrasonic treatment time is 18-25min, and the ultrasonic treatment temperature is 55-65°C;

[0052] (2) Weigh alkyl-modified organosiloxane, polydimethylsiloxane, neopentyl alcohol and isopropyl acetate, mix well, and cool the modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com