High-performance nano manganous fluoride cathode material and preparation method therefor

A negative electrode material, manganese fluoride technology, applied in the field of high-performance nano-manganese fluoride negative electrode materials and its preparation, can solve the problem that the electrochemical performance needs to be fully characterized and improved, and has not been studied in depth and meticulously, and the preparation of manganese fluoride nanomaterials and other problems, to achieve the effect of controllable shape, uniform size and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of a high-performance nano-manganese fluoride negative electrode material specifically includes the following steps:

[0032] (a) a certain amount of inorganic manganese salt is dissolved in a solvent (such as ethanol) to obtain a uniform solution, and then the fluorine-containing ionic liquid is dissolved in the uniform manganese salt solution;

[0033] (b) Stir the solution of step (a) at room temperature for 30 minutes to obtain a uniform solution, wherein the molar concentration of manganese ions is 0.01-2 moles / liter, and the molar concentration of the fluorine-containing ionic liquid is 0.01-2 moles / liter ;

[0034] (c) placing the solution obtained in the step (b) in a reaction kettle, and reacting under solvothermal conditions. The heating temperature range is 50-250°C, and the heating time range is 1-96 hours;

[0035] (d) separating, washing and drying the precipitate obtained in step (c) to obtain a high-performance nano manganese fluor...

Embodiment 1

[0051] Dissolve 0.5g of manganese acetate tetrahydrate in 30mL of ethanol, stir at room temperature for 10 minutes, then add 1mL of 1-butyl-4-methylimidazolium tetrafluoroborate to the above ethanol solution of manganese acetate tetrahydrate, and stir at room temperature for 20 minutes , and then transfer the above mixed solution to a 50mL hydrothermal kettle, and conduct a solvothermal reaction at 150°C for 36 hours. After cooling to room temperature, the precipitate is centrifuged, washed with ethanol and acetone several times, and dried in air at 65°C to obtain nano Manganese fluoride material;

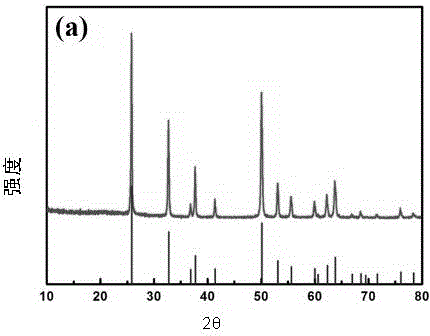

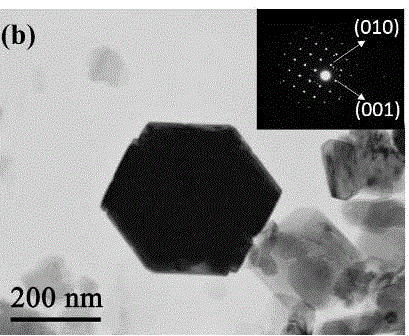

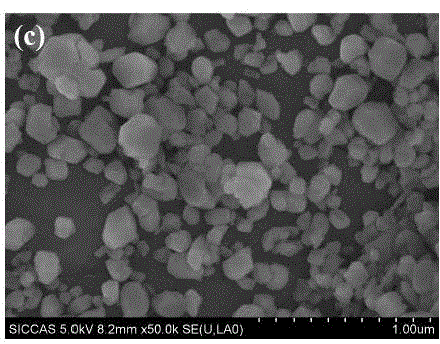

[0052] The samples were characterized by XRD, SEM and TEM, such as Figure 1a , 1b and 1c are shown. It can be seen from the figure that the as-prepared sample is a single tetragonal MnF 2 Phase, the shape is well-crystallized nanoparticles, the size is about 200-300nm, the results of selected area electron diffraction show that the nanocrystalline particles that make up the mater...

Embodiment 2

[0055] Dissolve 0.5g of manganese acetate tetrahydrate in 30mL of ethanol, stir at room temperature for 10 minutes, then add 1mL of 1-butyl-4-methylimidazolium tetrafluoroborate to the above ethanol solution of manganese acetate tetrahydrate, and stir at room temperature for 20 minutes , and then transfer the above mixed solution to a 50mL hydrothermal kettle, and conduct a solvothermal reaction at 120°C for 36 hours. After cooling to room temperature, the precipitate is centrifuged, washed with ethanol and acetone for several times, and dried in air at 65°C to obtain nano Manganese fluoride material;

[0056] The samples were characterized by XRD, TEM and SEM, such as Figure 2a , as shown in 2b and 2c. It can be seen from the figure that the as-prepared sample is a single tetragonal MnF 2 Phase, the shape is well-crystallized nanoparticles, the size is about 200-400nm, the results of selected area electron diffraction show that the nanocrystals that make up the material ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com