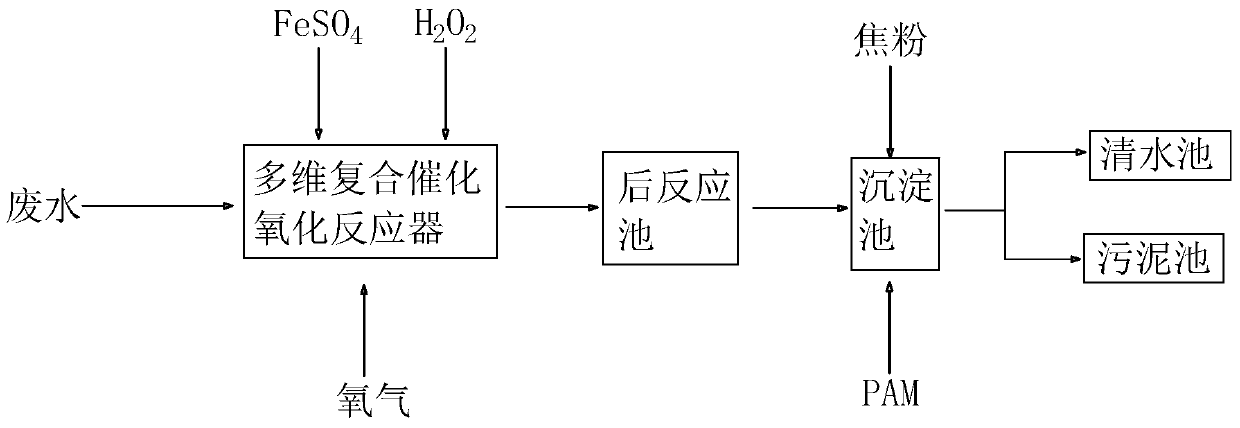

A method for advanced treatment of wastewater by multidimensional composite catalytic oxidation

A technology of catalytic oxidation and advanced treatment, applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., to achieve the effect of reducing the problem of color reversion, easy availability of raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) adding dilute nitric acid and urea to pseudo-boehmite dry rubber powder, and stirring at a high speed for 5 hours to obtain an aluminum sol with a solid mass fraction of 21%;

[0034] (2) According to parts by weight, immerse 110 parts of porous ceramics in the prepared aluminum sol for 1 minute, blow off the excess sol in the pores of the ceramics with compressed air after taking it out, and then place the porous ceramics at 32° C. to dry in the shade for 6 hours, Dry in an oven at 11°C for 6 hours, and finally bake in a muffle furnace at 600°C for 2 hours to obtain 8 parts of alumina;

[0035] (3) according to parts by weight, TiO 2 12 parts, CuFe 2 o 4 10 parts, 14 parts of iron filings and 1 part of activated carbon were filled into 2 / 3 of the pores of the ceramic, and fired in a muffle furnace at 600°C for 3 hours. After cooling, 7 parts of calcium oxalate were filled into the remaining 1 / 3 of the pores of the ceramic, pressed Just do it.

Embodiment 2

[0037] (1) adding dilute nitric acid and urea to pseudo-boehmite dry rubber powder, and stirring at a high speed for 5 hours to obtain an aluminum sol with a solid mass fraction of 21%;

[0038] (2) According to parts by weight, immerse 100 parts of porous ceramics in the prepared aluminum sol for 1 minute, blow off the excess sol in the pores of the ceramics with compressed air after taking it out, and then place the porous ceramics at 32°C to dry in the shade for 6 hours, Dry in an oven at 11°C for 6 hours, and finally bake in a muffle furnace at 600°C for 2 hours to obtain 5 parts of alumina;

[0039] (3) according to parts by weight, TiO 2 20 parts, CuFe 2 o 4 9 parts, 13 parts of iron filings and 3 parts of activated carbon were filled into 2 / 3 of the pores of the ceramic, and fired in a muffle furnace at 600°C for 3 hours. After cooling, 6 parts of calcium oxalate were filled into the remaining 1 / 3 of the pores of the ceramic, pressed Just do it.

Embodiment 3

[0041] (1) adding dilute nitric acid and urea to pseudo-boehmite dry rubber powder, and stirring at a high speed for 5 hours to obtain an aluminum sol with a solid mass fraction of 21%;

[0042] (2) According to parts by weight, immerse 105 parts of porous ceramics in the prepared aluminum sol for 1 minute, blow off the excess sol in the pores of the ceramics with compressed air after taking it out, and then place the porous ceramics at 32° C. to dry in the shade for 6 hours, Dry in an oven at 11°C for 6 hours, and finally bake in a muffle furnace at 600°C for 2 hours to obtain 7 parts of alumina;

[0043] (3) according to parts by weight, TiO 2 10 parts, CuFe 2 o 4 8 parts, 12 parts of iron filings and 2 parts of activated carbon were filled into 2 / 3 of the pores of the ceramic, and fired in a muffle furnace at 600°C for 3 hours. After cooling, 5 parts of calcium oxalate were filled into the remaining 1 / 3 of the pores of the ceramic, pressed Just do it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com