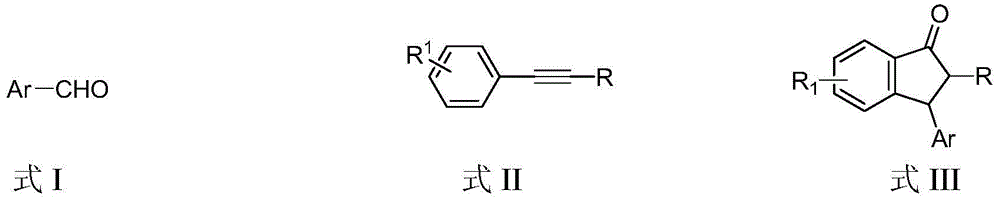

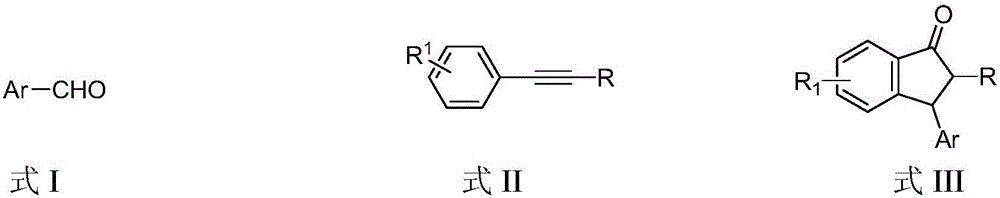

The preparation method of 3-aryl-1-indanone derivatives

A technology of indanone and derivatives, which is applied in the field of preparation of 3-aryl-1-indanone derivatives, can solve the problems of difficult purification of drugs or materials in the later stage, achieve reaction atom economy, easy purification of products, and synthesis The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, 2,3-diphenyl-2,3-indanone (in the formula III, R 1 is H, Ar is phenyl, R is phenyl)

[0023] Into a 25 mL reactor, add toluene (0.22 mmol, 39 mg), benzaldehyde (0.2 mmol, 20 μL), methyl trifluoromethanesulfonate (0.04 mmol, 4.6 μL) in sequence, and finally add 0.5 mL of 1,2 -Dichloroethane was used as a solvent, the reactor was sealed, and reacted at 50°C for 24 hours. After the reaction system was cooled, 15 mL of water and 15 mL of dichloromethane were added and stirred for 30 min, and then extracted three times with 15 mL of dichloromethane, and the organic phases were combined. The organic phase was washed with saturated brine, and finally dried over anhydrous magnesium sulfate for 0.5 h. After filtration, the organic phase was rotary evaporated to obtain a crude product. The crude product is separated by column chromatography using petroleum ether: ethyl acetate = 25:1 (volume ratio) as the eluent, and 200-300 mesh silica gel as the adsorption phase...

Embodiment 2

[0028] Example 2, 2-phenyl-3-p-methylphenyl-2,3-indanone (in formula III, R 1 is H, Ar is p-methylphenyl, R is phenyl)

[0029] To a 25mL reactor, add toluene (0.22mmol, 39mg), 4-methylbenzaldehyde (0.2mmol, 22μL), methyl trifluoromethanesulfonate (0.04mmol, 4.6μL), and finally add 0.5 Use mL of 1,2-dichloroethane as solvent, seal the reactor, and react at 50°C for 24 hours. After the reaction system was cooled, 15 mL of water and 15 mL of dichloromethane were added and stirred for 30 min, and then extracted three times with 15 mL of dichloromethane, and the organic phases were combined. The organic phase was washed with saturated brine, and finally dried over anhydrous magnesium sulfate for 0.5 h. After filtration, the organic phase was rotary evaporated to obtain a crude product. The crude product is separated by column chromatography with petroleum ether: ethyl acetate = 25:1 (volume ratio) as the eluent, and 200-300 mesh silica gel as the adsorption phase to obtain a yel...

Embodiment 3

[0034] Example 3, 2-phenyl-3-m-methylphenyl-2,3-indanone (in formula III, R 1 is H, Ar is m-methylphenyl, R is phenyl)

[0035]To a 25mL reactor, add toluene (0.22mmol, 39mg), 3-methylbenzaldehyde (0.2mmol, 22μL), methyl trifluoromethanesulfonate (0.04mmol, 4.6μL) in sequence, and finally add 0.5 Use mL of 1,2-dichloroethane as solvent, seal the reactor, and react at 50°C for 24 hours. After the reaction system was cooled, 15 mL of water and 15 mL of dichloromethane were added and stirred for 30 min, and then extracted three times with 15 mL of dichloromethane, and the organic phases were combined. The organic phase was washed with saturated brine, and finally dried over anhydrous magnesium sulfate for 0.5 h. After filtration, the organic phase was rotary evaporated to obtain a crude product. The crude product is separated by column chromatography with petroleum ether: ethyl acetate = 50:1 (volume ratio) as the eluent, and 200-300 mesh silica gel as the adsorption phase to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com