Structured iron-carbon micro-electrolysis filling material and preparation method thereof

A technology of iron-carbon micro-electrolysis and iron fine powder, which is applied in chemical instruments and methods, processing process wastewater treatment, food industry wastewater treatment, etc., can solve the problems of papermaking sludge disposal in papermaking enterprises, complex composition of papermaking sludge, fillers, etc. High cost of raw materials and other issues, to achieve the effect of improving electron transfer efficiency, improving internal electrolysis efficiency, and stabilizing treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

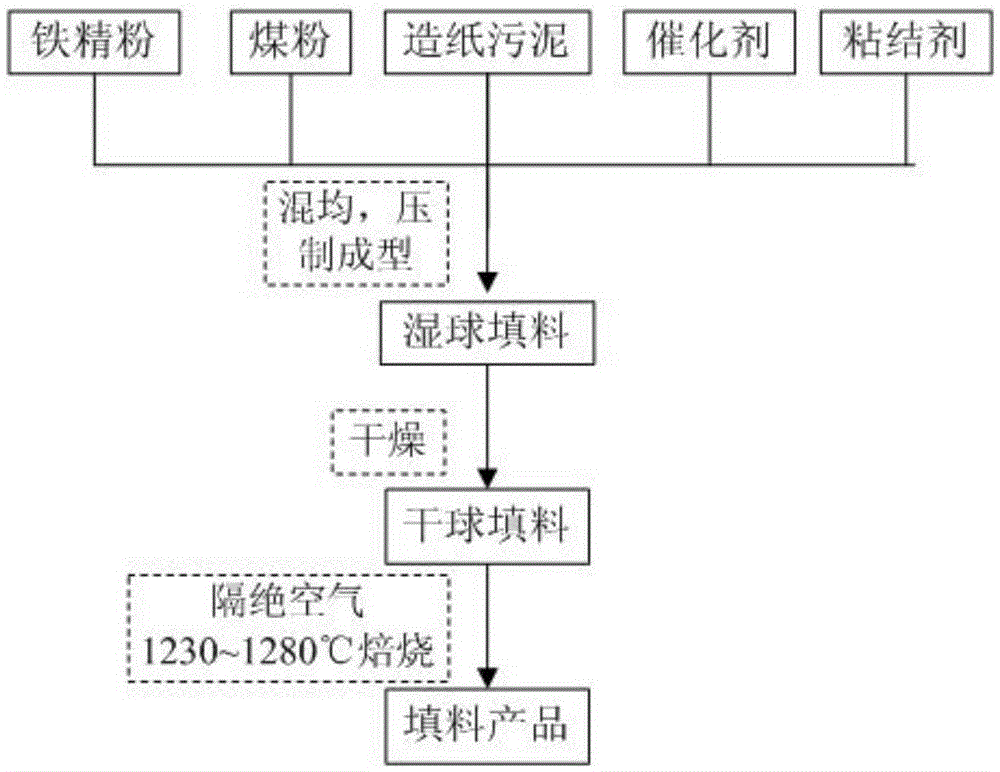

[0033] A method for preparing a regularized iron-carbon micro-electrolysis filler. The preparation method uses fine iron powder and bituminous coal powder as raw materials, uses dried and pulverized papermaking sludge as a pore-forming agent, uses copper powder as a catalyst, and adds viscose Agglomerates, mixed evenly, pressed into shape, and dried to obtain dry spherical fillers, and the iron fine powder in the dry spherical fillers was directly reduced by high-temperature roasting to generate anode metal iron, and iron-carbon micro-electrolytic fillers were prepared.

[0034] The fine iron powder used in the present invention is the product obtained through the purification of iron-containing minerals in the iron ore mine through the beneficiation process, and its main components are various iron oxides; while the preparation technology of conventional iron-carbon micro-electrolytic fillers uses commercially available iron powder, Commercially available iron powders are pron...

Embodiment 2

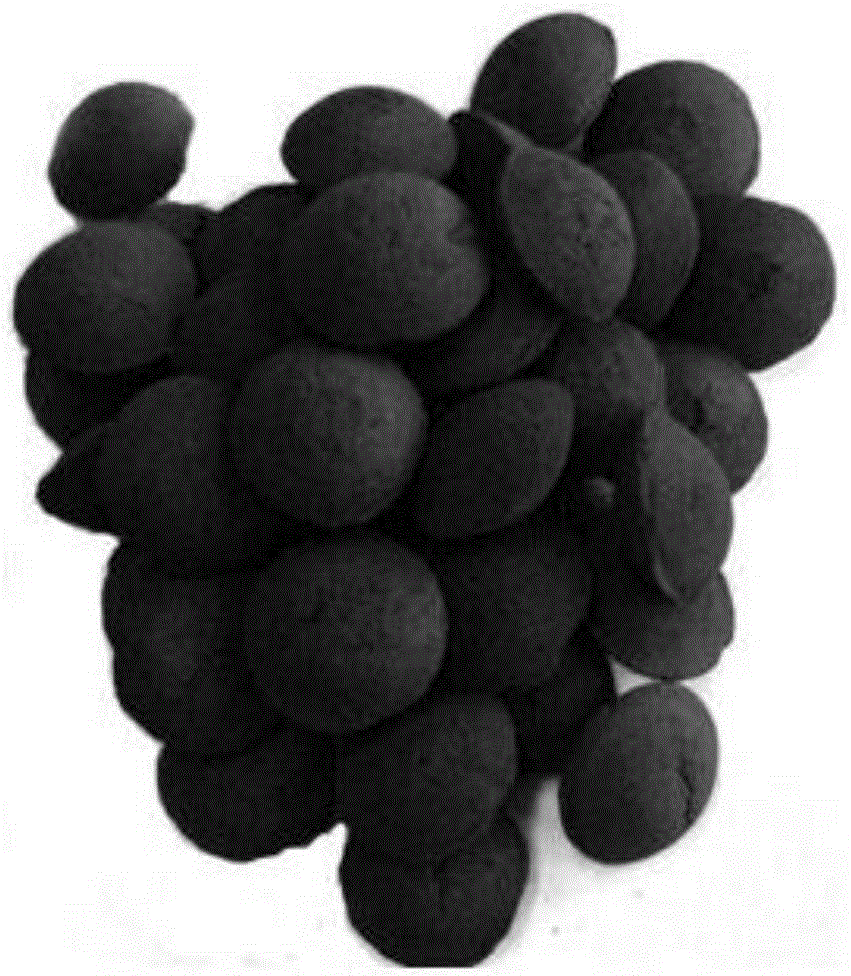

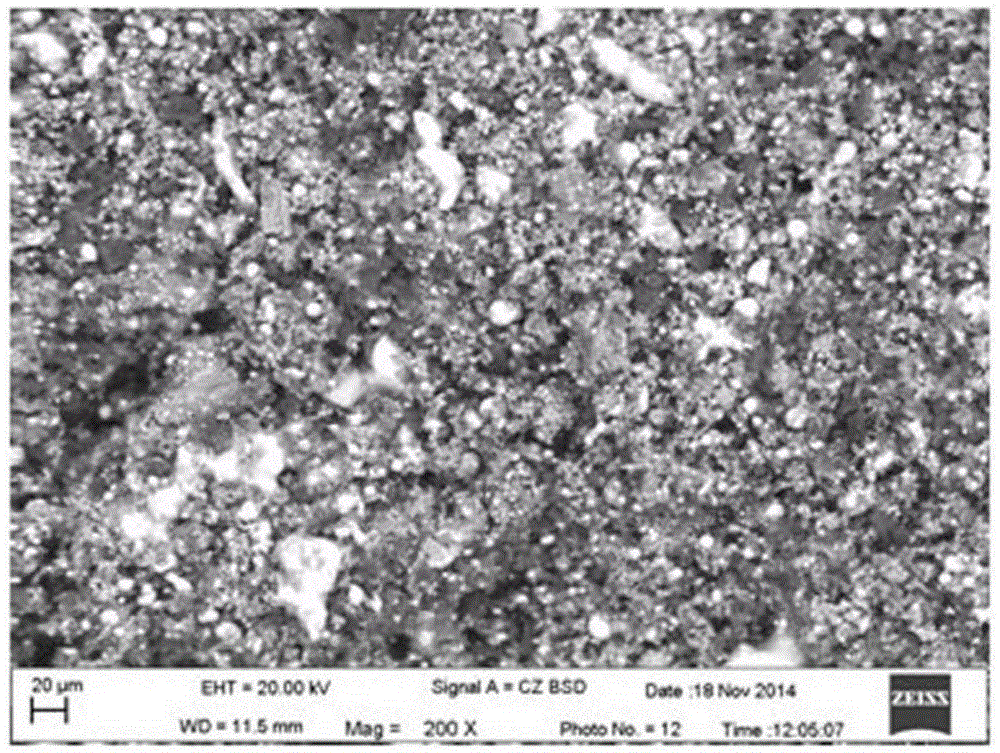

[0057] Mix iron concentrate powder, coal powder, papermaking sludge, copper powder and sodium silicate uniformly according to the mass ratio of 50:25:15:2:8, then adjust the moisture content of the mixture to 10%, and press it with high-pressure ball pressing equipment Form ellipsoidal wet filler balls with a diameter of 15mm, and dry them in a dryer at 80°C, place the dry filler balls in a high-temperature furnace isolated from air, bake them at 1230°C for 3 hours, and cool them down to below 400°C with air isolation , take out and cool naturally, and prepare regularized iron-carbon micro-electrolytic packing. The prepared filler has an iron-carbon integrated, porous honeycomb regular structure, the mass ratio of iron to carbon is 4.1:1, and the internal porosity is 54%.

[0058] Apply the regularized iron-carbon micro-electrolysis filler prepared in this example to treat simulated heavy metal wastewater containing lead and copper ions. The initial concentrations of lead and ...

Embodiment 3

[0060] The fine iron powder for ironmaking that has passed through a 200-mesh sieve, the bituminous coal powder that has passed through 200 mesh, the dried and pulverized papermaking sludge that has passed through 100 mesh, copper powder and bentonite that have passed through 200 mesh according to the mass ratio of 58:20:15:2: 5 Mix evenly to obtain the mixture, then adjust the moisture content of the mixture to 15%, press the mixture into an ellipsoidal wet ball filler with a diameter of 20mm, and dry the wet filler ball under a dryer Dry to obtain dry ball fillers, the drying temperature is 90°C, place the dry ball fillers in a high-temperature furnace isolated from air, and bake them at 1250°C for 2.5 hours, then cool them down to below 400°C with air isolation, take them out and cool them naturally, A regularized iron-carbon micro-electrolytic filler is prepared. The prepared iron-carbon micro-electrolytic filler has iron-carbon integrated, porous honeycomb regular structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com