Method for preparing synthesis gas from organic dissolvant and biomass residue

A biomass residue and organic solvent technology, applied in gasification process, manufacturing of combustible gas, petroleum industry, etc., can solve the problems of low-quality biomass energy waste, inability to remove harmful substances, low energy utilization rate, etc., to increase profits , Significant environmental protection benefits, the effect of reducing equipment investment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

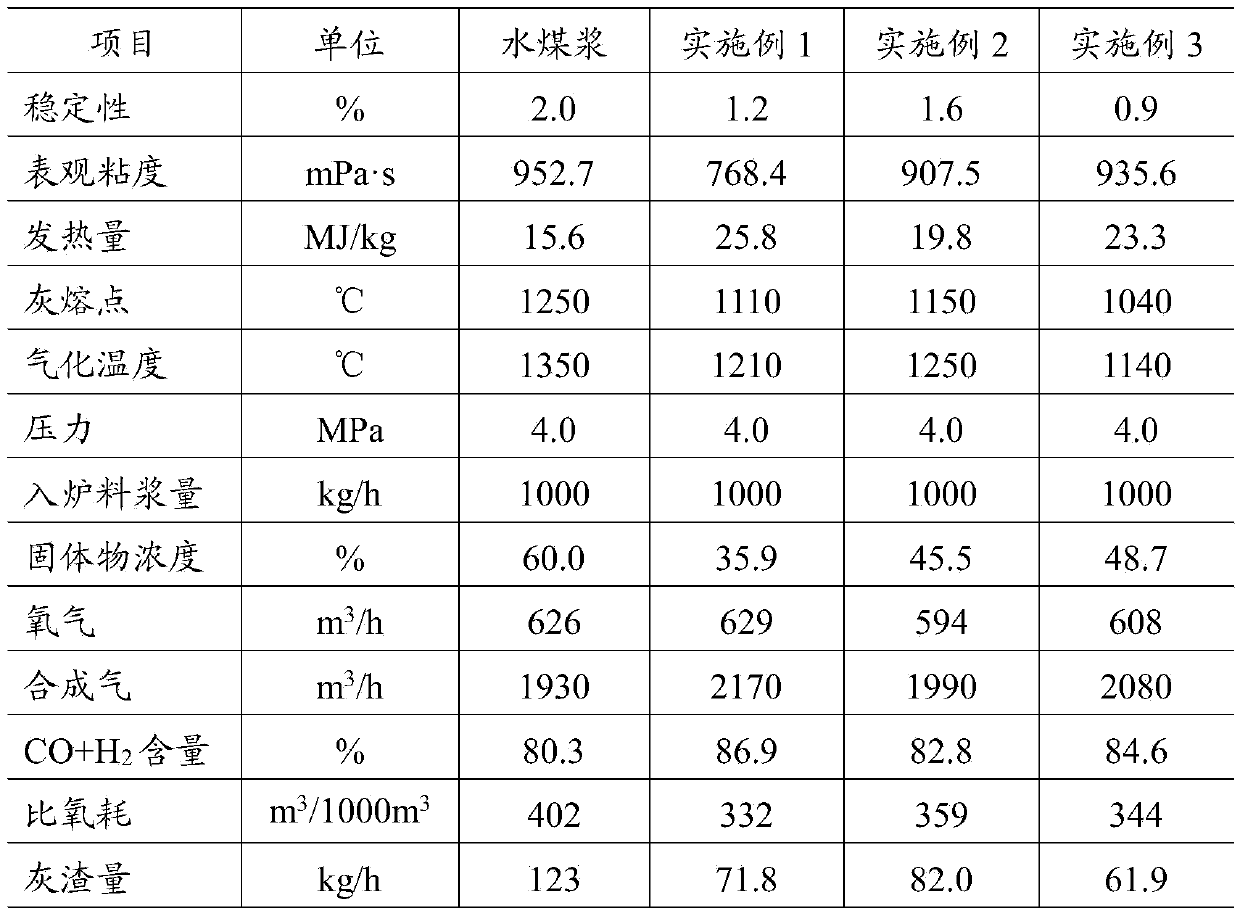

Embodiment 1

[0070] Example 1: Production of Syngas from Organic Solvents and Biomass Residues

[0071] The implementation steps of this embodiment are as follows:

[0072] A. Pretreatment

[0073] In this example, organic solvent waste butanol produced by a chemical company and oxytetracycline residue produced by a pharmaceutical company were used as raw materials for slurry preparation.

[0074] Use 1% hydrochloric acid solution by weight, sulfuric acid solution, phosphoric acid solution or 2% acetic acid solution pH value adjuster to adjust the pH value of organic solvent waste butanol to 7.0; obtaining a biomass residue powder whose particle size is 100% by weight less than 13 mm;

[0075] B. Slurry preparation

[0076] Add 60 parts by weight of waste butanol organic solvent obtained in step A, 40 parts by weight of biomass residue powder obtained in step A, and 0.4 parts by weight of auxiliary fatty alcohol polyoxyethylene ether dispersant into a mill and grind into a material pul...

Embodiment 2

[0083] Example 2: Preparation of Syngas from Organic Solvents and Biomass Residues

[0084] The implementation steps of this embodiment are as follows:

[0085] A. Pretreatment

[0086] In this example, organic solvent waste acetone produced by a pharmaceutical company and distiller's grains produced by a brewery company were used as raw materials for slurry preparation.

[0087] Use 1% aqueous sodium hydroxide solution, 2% aqueous ammonia solution or 5% aqueous sodium carbonate pH value regulator to adjust the pH value of the waste acetone organic solvent to 9.0; simultaneously use a crusher to crush the biomass residue distiller's grains to obtain a particle size by weight 100% biomass residue powder less than 13mm;

[0088] B. Slurry preparation

[0089] Add 50 parts by weight of the organic solvent obtained in step A, 50 parts by weight of the biomass residue powder obtained in step A and 0.05 parts by weight of auxiliary alkylphenol polyoxyethylene ether dispersant int...

Embodiment 3

[0095] Example 3: Preparation of Syngas from Organic Solvents and Biomass Residues

[0096] The implementation steps of this embodiment are as follows:

[0097] A. Pretreatment

[0098] In this example, organic solvent waste butanol produced by a pharmaceutical company and penicillin residue produced by a pharmaceutical company were used as raw materials for slurry preparation.

[0099] Use 1% aqueous sodium hydroxide solution, 2% aqueous ammonia solution or 5% aqueous sodium carbonate pH value regulator to adjust the pH value of the waste butanol organic solvent to 8.0; simultaneously use a crusher to crush the biomass residue penicillin scum to obtain a particle size of more than Biomass residue powder with 100% by weight less than 13mm;

[0100] B. Slurry preparation

[0101] Add 80 parts by weight of the organic solvent obtained in step A, 20 parts by weight of the biomass residue powder obtained in step A and 0.8 parts by weight of auxiliary fatty alcohol polyoxyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com