Ag/TiO2 flexible SERS substrate capable of being repeatedly utilized and preparation method thereof

A substrate and flexible technology, applied in the nano field, can solve the problems of weak silver nanoparticles on the surface of the film, complex SERS substrate process, poor reusability, etc., to achieve easy control of the reaction process, controllable amount of silver nanoparticles, and not easy to fall off. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

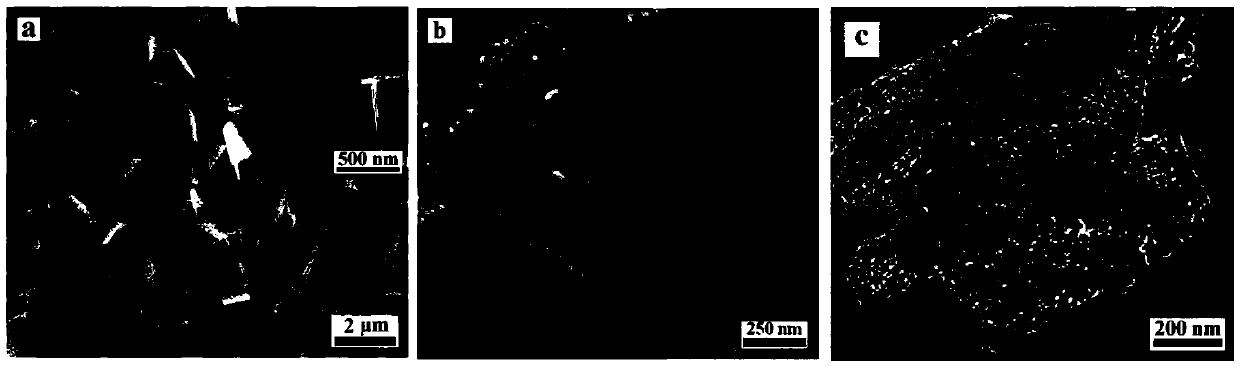

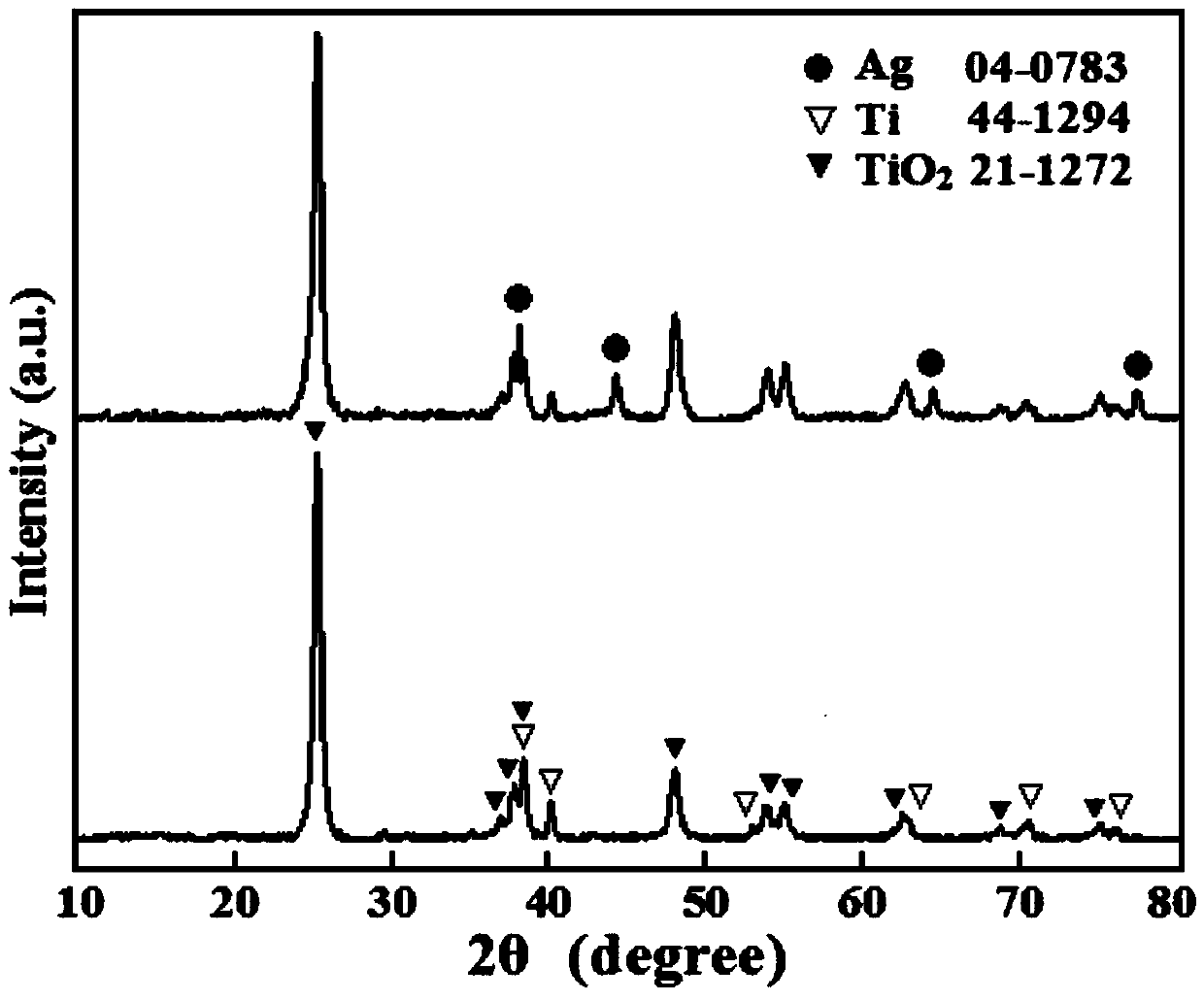

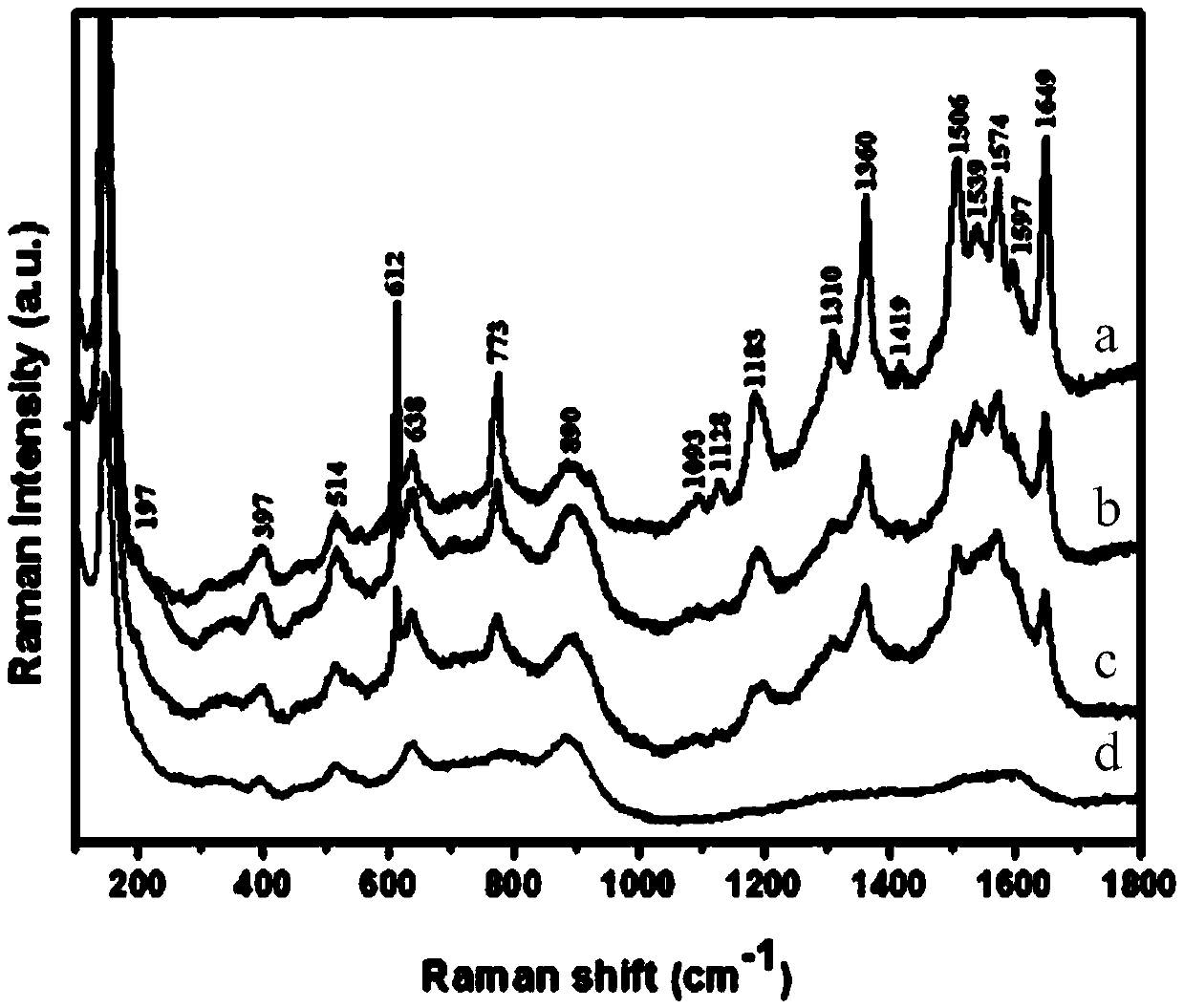

[0025] (1) Flatten a titanium sheet with a thickness of 0.2 mm and an area of 30 mm × 10 mm, and then use acetone and ethanol to ultrasonically clean it for 30 minutes, then use chemical polishing to polish the polished Ti sheet. Under the protection of nitrogen, blow dry with cold air for later use. Chemical polishing adopts impregnation method, and the volume ratio is HF:HNO 3 :H 2 O=1:1:4 in a mixed solution, and polish until the oxide layer on the surface of the titanium sheet is completely dissolved and turns bright silver; (2) Lean one side of the polished titanium sheet in a polytetrafluoroethylene with a volume of 100ml In the lined high-pressure reaction kettle, slowly add the prepared 4mol / L NaOH aqueous solution until the titanium sheet is completely submerged, cover it and place it in a blast drying oven at 200°C for 48 hours at a constant temperature; (3) use tweezers to Take out the sample carefully, rinse it repeatedly with deionized water, soak it in 0.1mol...

Embodiment 2

[0031] (1) Clean the titanium sheet sequentially with acetone and ethanol for 40 minutes, then chemically polish it, rinse it repeatedly with distilled water, and dry it with cold air under the protection of nitrogen for later use; (2) lean one side of the polished titanium sheet against high pressure In the reaction kettle, slowly add NaOH aqueous solution with a concentration of 4.5mol / L until the titanium sheet is completely submerged, cover the autoclave and place it in a blast drying oven for 40 hours at a constant temperature of 220°C; (3) Take out the titanium sheet and use a deionized After repeated washing with water, soak in 0.12mol / L HCl solution for 14 hours, then take out the titanium sheet, rinse it repeatedly with deionized water, dry it with cold air, and then anneal in a muffle furnace at 420°C for 3.5 hours and then cool it naturally to room temperature. TiO obtained in anatase phase 2 Nanobelt; (4) TiO 2 The nanoribbons were first soaked in 50mL of AgNO wit...

Embodiment 3

[0033] (1) Clean the titanium sheet sequentially with acetone and ethanol for 20 minutes, then chemically polish it, rinse it repeatedly with distilled water, and dry it with cold air under the protection of nitrogen for later use; (2) lean one side of the polished titanium sheet against a high pressure In the reaction kettle, slowly add NaOH aqueous solution with a concentration of 3.5mol / L until the titanium sheet is completely submerged, cover the autoclave and place it in a blast drying oven for 56 hours at a constant temperature of 180°C; (3) Take out the titanium sheet and use a deionized After repeated washing with water, soak in 0.08mol / L HCl solution for 10 hours, then take out the titanium sheet, rinse it repeatedly with deionized water, dry it with cold air, then anneal in a muffle furnace at 380°C for 2.5 hours and then cool it naturally to room temperature. TiO obtained in anatase phase 2 Nanobelt; (4) TiO 2 The nanoribbons were first soaked in 50mL of AgNO with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com