Preparation process for injection ceftiofur sodium with unqualified products convenient to eliminate

A technology of ceftiofur sodium and preparation process, applied in the field of medicine, can solve problems such as unqualified finished products of ceftiofur sodium, and achieve the effects of avoiding unlabeled, suitable for industrial production and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

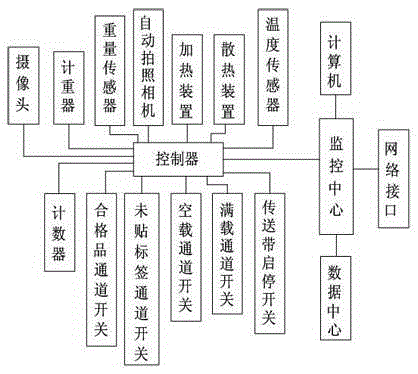

[0024] Such as figure 1 Shown, the preparation technology of the ceftiofur sodium for injection that is convenient to reject unqualified product comprises the following steps:

[0025] 1) Synthesis of ceftiofur sodium: use 7-aminocephalosporanic acid as the raw material, use tetrahydrofuran and purified water as the solvent in a ratio of 1:3, and obtain the triethylamine salt of ceftiofur after reaction, and then in tetrahydrofuran After reacting with sodium isooctanoate, the precipitate of ceftiofur sodium is obtained, the ratio of tetrahydrofuran to sodium isooctanoate is 2:1, the precipitate is washed with ethanol, and the wet product of ceftiofur sodium is obtained after filtration under reduced pressure;

[0026] 2), drying and grinding the prepared ceftiofur sodium wet product into powder;

[0027] 3) The preparation process of ceftiofur sodium: first clean the reagent bottle used to hold the ceftiofur sodium powder, then quantitatively fill the ceftiofur sodium powder ...

Embodiment 2

[0029] Such as figure 1 Shown, the preparation technology of the ceftiofur sodium for injection that is convenient to reject unqualified product comprises the following steps:

[0030] 1) Synthesis of ceftiofur sodium: 7-aminocephalosporanic acid is used as raw material, tetrahydrofuran and purified water are used as solvents in a ratio of 1:4, and the triethylamine salt of ceftiofur is obtained through reaction, and then in tetrahydrofuran After reacting with sodium isooctanoate, the precipitate of ceftiofur sodium is obtained, the ratio of tetrahydrofuran to sodium isooctanoate is 3:1, the precipitate is washed with n-propanol, and the wet product of ceftiofur sodium is obtained after filtration under reduced pressure;

[0031] 2), drying and grinding the prepared ceftiofur sodium wet product into powder;

[0032] 3) The preparation process of ceftiofur sodium: first clean the reagent bottle used to hold the ceftiofur sodium powder, then quantitatively fill the ceftiofur sodi...

Embodiment 3

[0034] Such as figure 1 Shown, the preparation technology of the ceftiofur sodium for injection that is convenient to reject unqualified product comprises the following steps:

[0035] 1) Synthesis of ceftiofur sodium: use 7-aminocephalosporanic acid as the raw material, use tetrahydrofuran and purified water as the solvent in a ratio of 1:5, react to obtain the triethylamine salt of ceftiofur, and then dissolve it in methanol After reacting with sodium 2-ethylhexanoate, the precipitate of ceftiofur sodium is obtained, the ratio of methanol to sodium isooctanoate is 2:1, the precipitate is washed with ethylene glycol, and then filtered under reduced pressure to obtain the wet product of ceftiofur sodium;

[0036] 2), drying and grinding the prepared ceftiofur sodium wet product into powder;

[0037] 3) The preparation process of ceftiofur sodium: first clean the reagent bottle used to hold the ceftiofur sodium powder, then quantitatively fill the ceftiofur sodium powder into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com