Packaging material of high capacity film capacitor

A technology of packaging materials and film capacitors, applied in the direction of hybrid box/housing/packaging, etc., can solve the problems of low stress, high thermal conductivity, etc., achieve good flow performance, good heat and humidity resistance, and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

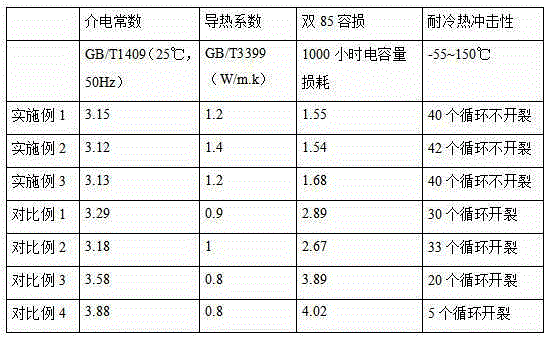

Examples

Embodiment 1

[0036] A packaging material for a large-capacity film capacitor, the packaging material is formed by mixing components A and B, and the weight ratio of component A to component B is 1:1~1.2;

[0037] The A component includes the following raw materials in parts by weight: 10 parts of bismaleimide modified phenolic resin; 2 parts of epoxy resin; 3 parts of ethyl acetate; 5 parts of butyl glycidyl ether;

[0038] The B component includes the following raw materials in parts by weight: 7 parts of modified amine curing agent; 6 parts of zinc N-ethyl-N-phenyldithiocarbamate; 3 parts of thermal conductivity reinforcing agent; tetrakis (4-hydroxy 1 part of pentaerythritol ester of -2,5-tert-butylphenylpropionate; 8 parts of anilinomethyltriethoxysilane; 1.5 parts of ethyl imidazole; 0.3 parts of anti-settling agent; 0.2 parts of defoaming agent.

Embodiment 2

[0040] A packaging material for a large-capacity film capacitor, the packaging material is formed by mixing two components, A and B, and the weight ratio of component A to component B is 1:1.1;

[0041] The A component includes the following raw materials in parts by weight: 15 parts of bismaleimide modified phenolic resin; 5 parts of epoxy resin; 8 parts of ethyl acetate; 15 parts of butyl glycidyl ether;

[0042] The B component includes the following raw materials in parts by weight: 9 parts of modified amine curing agent; 9 parts of zinc N-ethyl-N-phenyldithiocarbamate; 6 parts of thermal conductivity reinforcing agent; tetrakis (4-hydroxy 2 parts of -2,5-tert-butylphenylpropionic acid) pentaerythritol ester; 15 parts of anilinomethyltriethoxysilane; 2.5 parts of ethyl imidazole; 0.6 parts of anti-settling agent; 0..5 parts of defoaming agent.

Embodiment 3

[0044] A packaging material for large-capacity film capacitors, the packaging material is formed by mixing two components, A and B, and the weight ratio of component A to component B is 1:1.2;

[0045] The A component includes the following raw materials in parts by weight: 25 parts of bismaleimide modified phenolic resin; 9 parts of epoxy resin; 15 parts of ethyl acetate; 25 parts of butyl glycidyl ether;

[0046] The B component includes the following raw materials in parts by weight: 15 parts of modified amine curing agent; 15 parts of zinc N-ethyl-N-phenyldithiocarbamate; 12 parts of thermal conductivity reinforcing agent; tetrakis (4-hydroxy -2,5-tert-butylphenylpropionic acid) 3 parts of pentaerythritol ester; 25 parts of anilinomethyltriethoxysilane; 3.5 parts of ethyl imidazole; 1.6 parts of anti-settling agent; 1.5 parts of defoamer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com