Method for manufacturing nanoflower film based on manganese cobalt oxide hierarchy structure

A graded structure, manganese cobalt oxide technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of difficult three-dimensional materials, affecting the performance of synthetic materials, and difficult to remove templates, which is easy to batch. Production, strong practicability, mild and controllable experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Add 2mmol of cobalt chloride, 1mmol of manganese chloride, 4mmol of hexamethylenetetramine, and 2mmol of ammonium fluoride powder into 80ml of distilled water, put it in a 100ml beaker, put it into an ultrasonic instrument for 5 minutes, and use a magnetic stirrer Stir for 30 minutes to combine well.

[0031] Pour the above solution into a 100ml polytetrafluoroethylene-lined reaction kettle, take out a piece of activated nickel foam and add it to the above reaction kettle, seal it, place it in an oven, control the temperature of the oven to 100°C, and react for 12 hours , cooled to room temperature, washed and dried in vacuum to obtain the manganese cobaltate precursor.

[0032] The manganese cobaltate precursor grown on the surface of nickel foam was put into a tube furnace for calcination at 500°C, the heating rate was 1 degree per minute, and the temperature was kept for 2 hours to obtain a manganese cobaltate hierarchical structure nanoflower film.

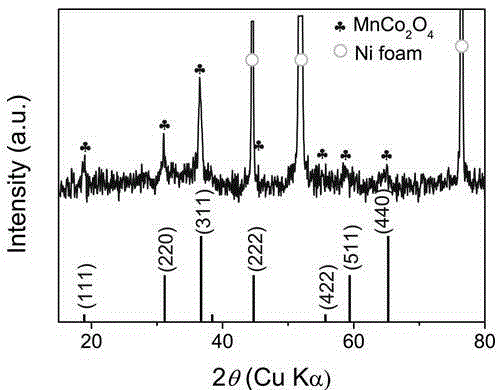

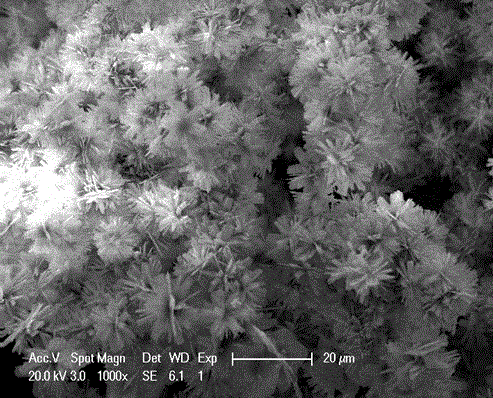

[0033] figure...

Embodiment 2

[0036] Add 2mmol of cobalt chloride, 1mmol of manganese chloride, 6mmol of hexamethylenetetramine, and 5mmol of ammonium fluoride powder into 80ml of distilled water, put it in a 100ml beaker, put it into an ultrasonic instrument for 5 minutes, and use a magnetic stirrer Stir for 30 minutes to combine well.

[0037] Pour the above solution into a reaction kettle with a PTFE substrate of 100 milliliters, take out a piece of activated nickel foam and add it to the above reaction kettle, seal it, place it in an oven, control the temperature of the oven to 120°C, and react for 10 hours, cooled to room temperature, washed, and vacuum-dried to obtain the manganese cobaltate precursor.

[0038] The manganese cobaltate precursor grown on the surface of nickel foam was put into a tube furnace for calcination at 400°C, the heating rate was 2 degrees per minute, and the temperature was kept for 6 hours to obtain a manganese cobaltate hierarchical structure nanoflower film.

[0039] The ...

Embodiment 3

[0041] Add 2mmol of cobalt chloride, 1mmol of manganese chloride, 10mmol of hexamethylenetetramine, and 5mmol of ammonium fluoride powder into 80ml of distilled water, put it in a 100ml beaker, put it into an ultrasonic instrument for 5 minutes, and use a magnetic stirrer Stir for 30 minutes to combine well.

[0042] Pour the above solution into a 100ml polytetrafluoroethylene-lined reaction kettle, take out a piece of activated nickel foam and add it to the above reaction kettle, seal it, place it in an oven, control the temperature of the oven to 150°C, and react for 8 hours , cooled to room temperature, washed and dried in vacuum to obtain the manganese cobaltate precursor.

[0043] The manganese cobaltate precursor grown on the surface of nickel foam was put into a tube furnace for calcination at 300°C, the heating rate was 5 degrees per minute, and the temperature was kept for 9 hours to obtain a manganese cobaltate hierarchical structure nanoflower film.

[0044] The X-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com