Brain protein hydrolysate preparation method

A technology of cerebroprotein hydrolyzate and enzymatic hydrolysis, which is applied in the field of biochemical pharmacy, can solve the problems of high hygroscopicity, which is not conducive to the production of cerebroprotein hydrolyzate tablets, high viscosity of cerebroprotein extract powder, and large amount of organic solvent. Improve the function of brain cells, reduce the degree of emulsification and viscosity, and restore brain vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

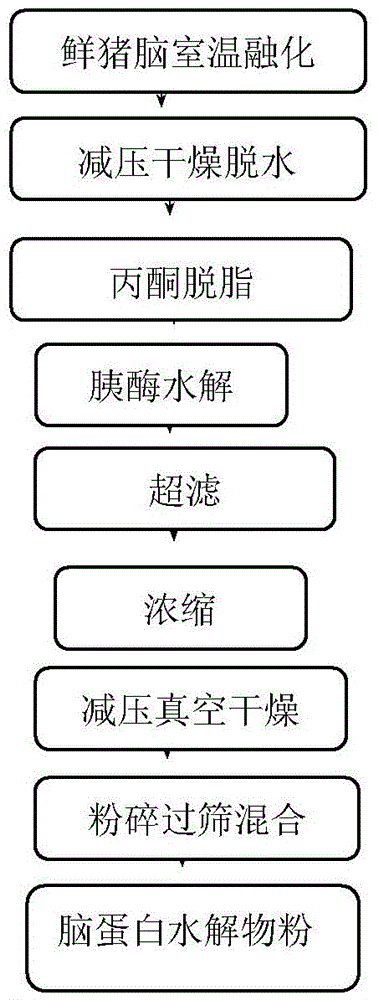

Image

Examples

Embodiment 1

[0022] 1. Raw material pretreatment dehydration and degreasing:

[0023] Take the pig brain, melt it at room temperature to remove the fascia and mince it, then dry it in a vacuum drying oven at 50°C and a vacuum degree below -0.085MPa, and grab a plate immediately after drying (strictly control the drying temperature not to exceed 60°C) to obtain brain dry powder .

[0024] Take the dry brain powder and soak it in acetone with 3 times the mass of the dry powder for 18 hours, then change the acetone to soak, repeat the treatment 3 times, then filter, press the filter residue, and vacuum dry the filter residue at 50 °C for 12 hours; Stir every hour.

[0025] 2. Trypsin hydrolysis:

[0026] Add the dried filter residue to 10 times (w / w) water of the filter residue, stir evenly, adjust the pH of the system with ammonia to 8.0, heat it in a water bath to 52°C, add 4% (w / w) of the above-mentioned dried filter residue / W) trypsinogen powder, under 52 DEG C, keep stirring and hydr...

Embodiment 2

[0032] 1. Raw material pretreatment dehydration and degreasing:

[0033] Take the pig brain, melt it at room temperature to remove the fascia, shred it, and dry it in a vacuum drying oven at 60°C with a vacuum degree below -0.085MPa. After drying, grab a plate immediately (strictly control the drying temperature not to exceed 60°C) to obtain brain dry powder .

[0034] Take the dry brain powder and soak it in acetone with 2 times the mass of the dry powder for 20 hours, then change the acetone to soak, repeat the treatment twice, then filter, press the filter residue, and vacuum dry the filter residue at 50°C for 12 hours; Stir every hour.

[0035] 2. Trypsin hydrolysis:

[0036] Add the dried filter residue to 12 times (w / w) water of the filter residue, stir evenly, use ammonia to adjust the pH of the system to 8.5, heat it in a water bath to 48°C, and add 5% (W / w) of the above-mentioned dried filter residue W) trypsinogen powder, heat-preserved and stirred at 48°C for 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com