Multifunctional probe and preparation method and application thereof

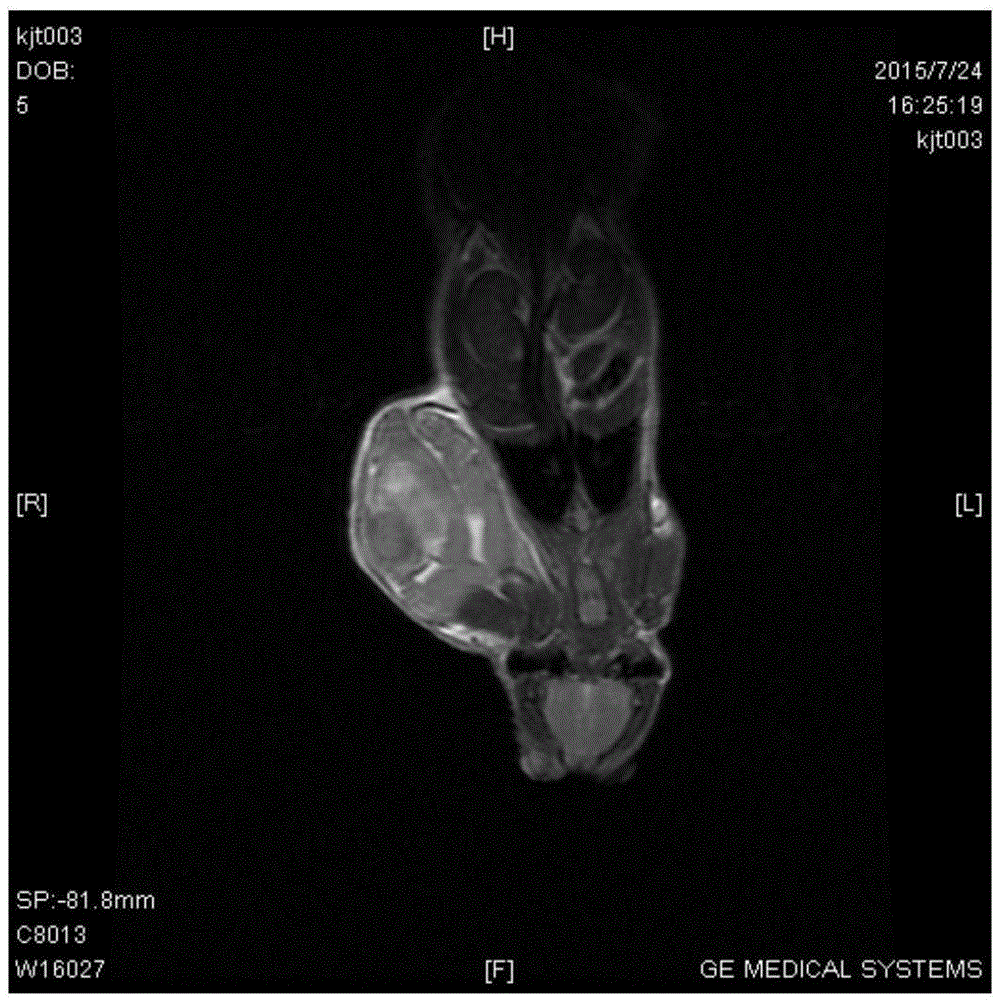

A multi-functional probe and probe technology, applied in the field of multi-functional probe and its preparation, nano-gold rod diagnosis and treatment probe, can solve the problems of low yield and cumbersome preparation process, and achieve simple preparation, easy metabolism, The effect of excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

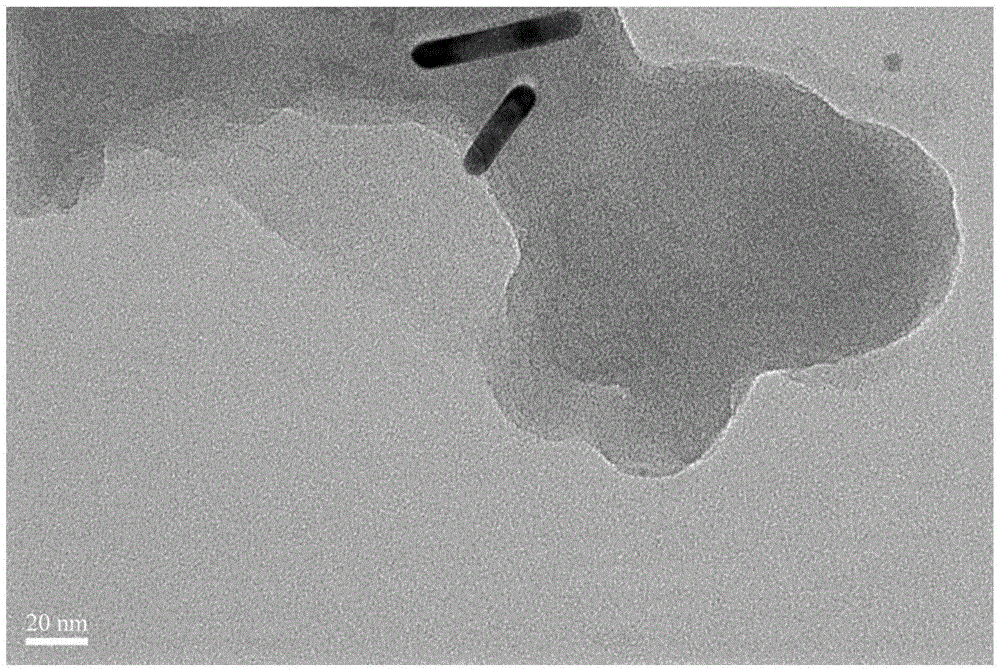

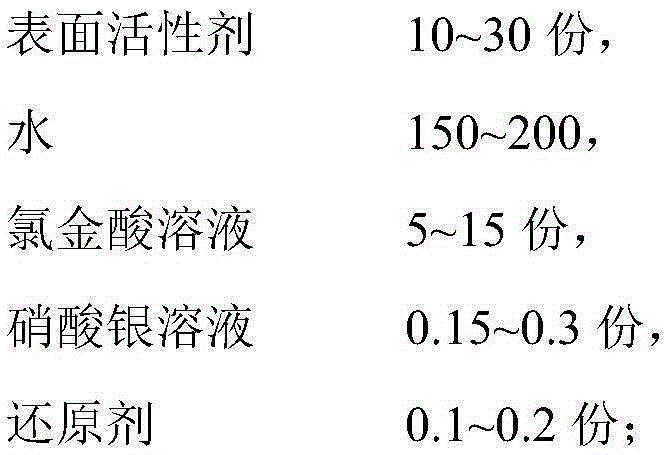

[0068] a. Add 10 parts of cetyltrimethylammonium bromide to 150 parts of deionized water, stir at 50°C for 1 hour, after the surfactant is completely dissolved, add 10 parts of chloroauric acid solution with a mole fraction of 10 μM After a little stirring, 0.15 parts of a silver nitrate solution with a mole fraction of 0.25 mM was added. After stirring evenly, 0.1 part of sodium borohydride was added and then a sol mixture was generated, followed by incubating at 37° C. for 10 hours, and centrifuging and washing with deionized water at 9000 rpm to obtain a concentrated solution of gold nanorods from which the surfactant was removed.

[0069] b. Add 200 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide sodium hydrochloride to 10 parts of deionized water. After the cross-linking agent is dissolved, add 400 parts of sodium hyaluronate powder Add and stir for 3 hours to obtain a sodium hyaluronate solution with activated carboxyl groups.

[0070] c. Disperse 5 parts of the ...

Embodiment 2

[0075] a. Add 20 parts of cetyltrimethylammonium bromide to 200 parts of deionized water, stir at 60°C for 1 hour, after the surfactant is completely dissolved, add 15 parts of chloroauric acid solution with a mole fraction of 10 μM After a little stirring, 0.3 parts of a silver nitrate solution with a mole fraction of 0.25 mM was added. After stirring evenly, 0.1 part of sodium borohydride was added to generate a sol mixture, followed by incubating at 37°C for 12 hours, and centrifuging and washing with deionized water at 9000 rpm to obtain a concentrated solution of gold nanorods from which the surfactant was removed.

[0076] b. Add 200 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide potassium hydrochloride to 10 parts of deionized water. After the cross-linking agent is dissolved, add 300 parts of sodium hyaluronate powder Add and stir for 3 hours to obtain a sodium hyaluronate solution with activated carboxyl groups.

[0077] c. Disperse 10 parts of gold nanorod c...

Embodiment 3

[0082] a. Add 30 parts of cetyltrimethylammonium bromide to 200 parts of deionized water, stir for 1 hour above 80 ° C, and after the surfactant is completely dissolved, add 15 parts of chloroauric acid with a mole fraction of 10 μM After the solution was stirred for a while, 0.2 parts of silver nitrate solution with a mole fraction of 0.25 mM was added. After stirring evenly, 0.2 parts of sodium borohydride was added to form a sol mixture, followed by incubating at 40°C for 14 hours, and centrifuging and washing with deionized water at 9500 rpm to obtain a concentrated solution of gold nanorods from which the surfactant was removed.

[0083] b. Add 100 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide potassium hydrochloride to 10 parts of deionized water. After the cross-linking agent is dissolved, add 500 parts of sodium hyaluronate powder Add and stir for 3 hours to obtain a sodium hyaluronate solution with activated carboxyl groups.

[0084] c. Disperse 10 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com