Composite mesoporous molecular sieve solid superacid and preparation method thereof

A mesoporous molecular sieve and solid superacid technology, which is applied in the preparation of carboxylate esters, molecular sieve catalysts, and organic compounds, can solve the problems of low density of solid superacid acid centers, short service life of catalysts, and low catalytic activity. Achieve uniform distribution of active centers, mild preparation conditions, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

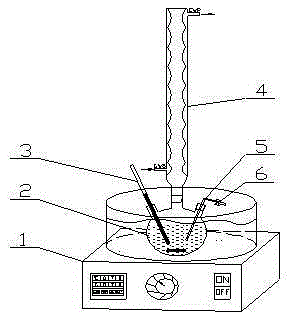

Method used

Image

Examples

Embodiment 1

[0042] TiO 2 The effect of loading rate on the catalytic activity of solid super acid:

[0043] At room temperature, add 1g of each MAS-5 mesoporous molecular sieve into a beaker containing 5-20ml of sol, magnetically stir for 30 minutes, and then sonicate for 40 minutes; ensure that the inner surface of the MAS-5 mesoporous molecular sieve is in full contact with the sol; Pressure distillation, evaporate the solvent, and vacuum-dry at 70℃ and 0.09MPa vacuum degree for 4h; take it out and grind it into powder with agate, and calcinate in a muffle furnace at 500℃ for 3h;

[0044] Take 1g of loaded TiO 2 MAS-5 molecular sieve is placed in a watch glass, and 2mol / L H 2 SO 4 Add 3.8g of the solution dropwise to the watch glass where the molecular sieve is placed. Stir slowly with a glass rod, and it is creamy. After stirring, put it in a vacuum drying oven at 70℃ and dry for 4h; after grinding it into powder, place it in a muffle furnace Calcined at 450°C for 4 hours to obtain a solid ...

Embodiment 2

[0054] TiO 2 Calcination temperature for doped 37.5%TiO 2 The effect of solid super acid on catalytic activity:

[0055] Same operation as in Example 1, but its TiO 2 The calcination temperatures were 475°C, 500°C, and 530°C, respectively, and the activity evaluation results of the obtained new composite mesoporous molecular sieve solid superacid are shown in Table 2.

[0056] Table 2TiO 2 Effect of calcination temperature on catalytic activity of catalyst

[0057]

[0058] It can be seen from Table 2 that TiO 2 When the calcination temperature is 500℃, the catalyst activity is ideal.

Embodiment 3

[0060] Impregnated H 2 SO 4 The influence of solution concentration on the catalytic activity of solid super acid:

[0061] Same operation as in Example 1, but the impregnated H 2 SO 4 The solution concentrations were 1 mol / L, 2 mol / L, and 3 mol / L, and the activity evaluation results of the obtained composite mesoporous molecular sieve solid super acid are shown in Table 3.

[0062] Table 3 The influence of impregnated sulfuric acid concentration on the catalytic activity of the catalyst

[0063]

[0064] It can be seen from Table 3 that H 2 SO 4 Solution immersion concentration 2mol / L, SO 4 2- When the loading rate is 35.23%, the catalytic activity of the obtained catalyst is ideal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com