High-weatherability water-borne printing ink for PVC wallpaper and preparation method thereof

A water-based ink with high weather resistance technology, which is applied in ink, applications, household appliances, etc., can solve the problems of difficult to achieve ink weather resistance, easy yellowing and chalking of printed matter, and achieve superior performance, improved temperature and weather resistance, and easy to use The effect of life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

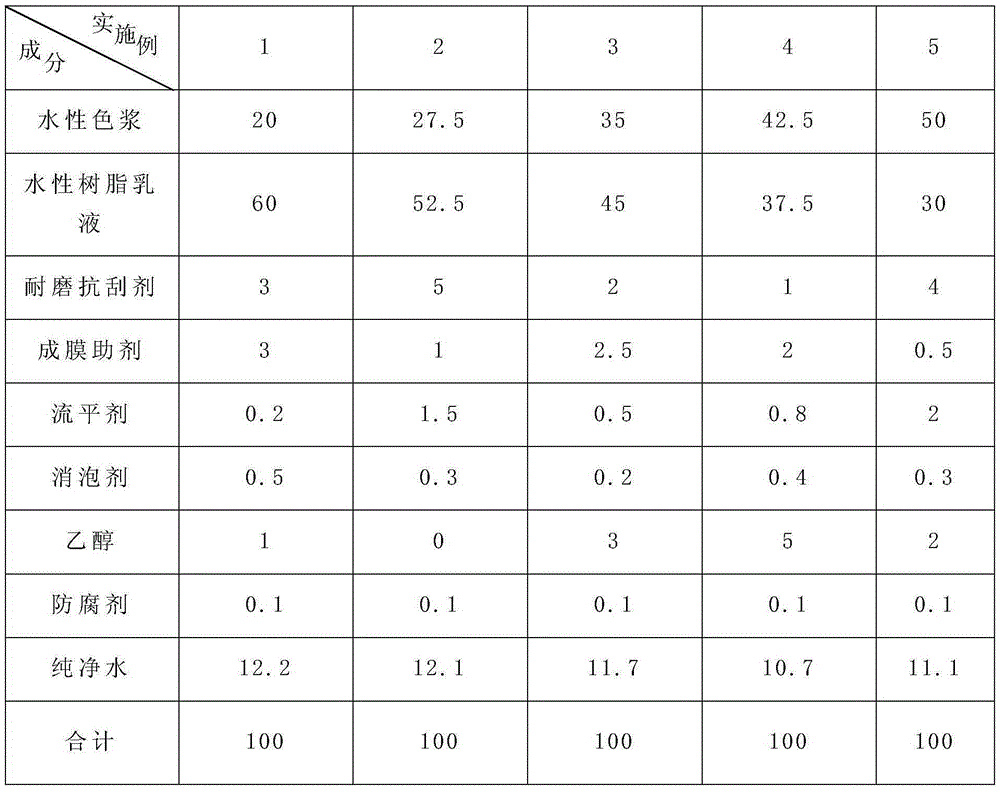

[0025] Table 1 shows the mass percentages of high weather resistance water-based inks for PVC paper in Examples 1-5.

[0026] Table 1

[0027]

[0028] Ethanol is a non-essential solvent that only provides quick drying and a little leveling effect, and is a non-toxic solvent that is allowed to be added by national regulations.

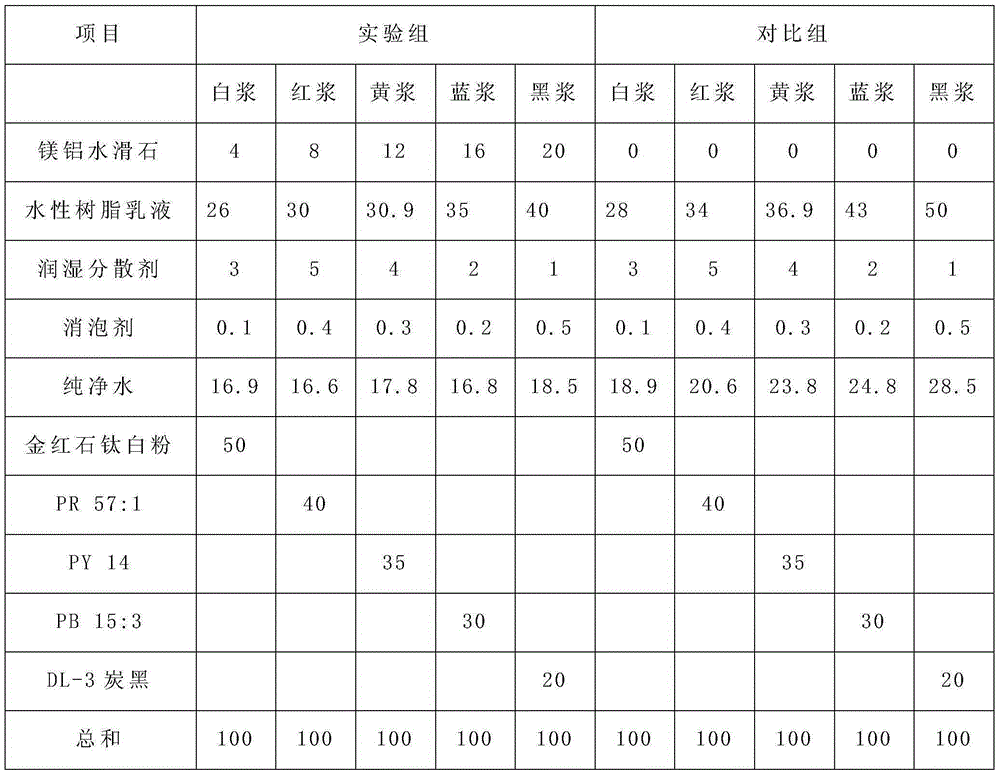

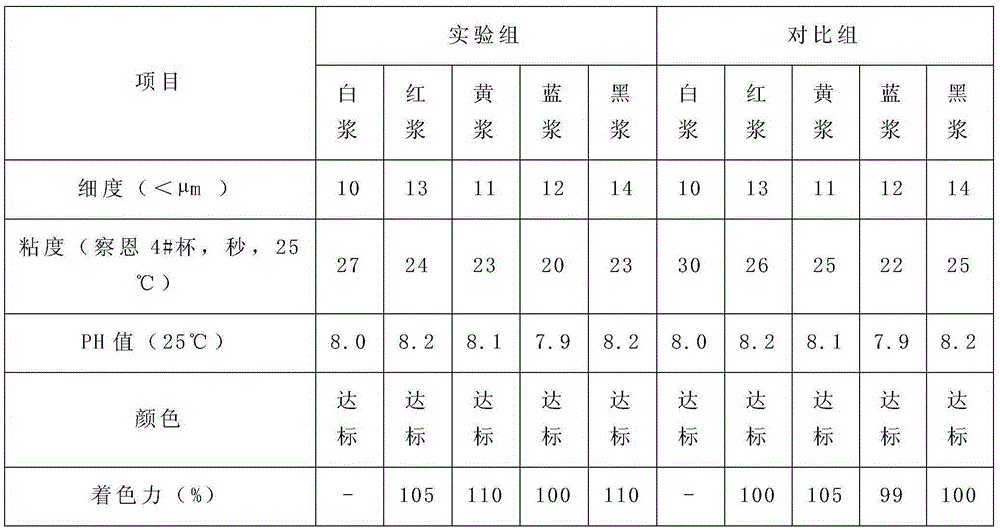

[0029] In the foregoing embodiments, the water-based color paste is composed of 20-50% pigment by mass percentage, 15-60% water-based resin emulsion, 1-20% magnesium aluminum hydrotalcite, 0-5% wetting and dispersing agent, 0.1 ~0.5% defoamer, 10~40% pure water are ground in a sand mill, and the pigment is one of rutile titanium dioxide, PR57:1, PY14, PB15:3 or DL-3 carbon black Specific values are shown in Table 2.

[0030] Table 2

[0031]

[0032] The magnesium-aluminum hydrotalcite is a surface-modified magnesium-aluminum hydrotalcite with special properties, has good infrared absorption and ultraviolet blocking functions, and can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com