Metallized ferrite magnetic core and preparation method thereof

A ferrite core and metallization technology, applied in inductors with magnetic cores, metal material coating processes, transformer/inductor cores, etc. High consumption, poor performance and other problems, to achieve the effects of no economy, fast film formation by sputtering, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

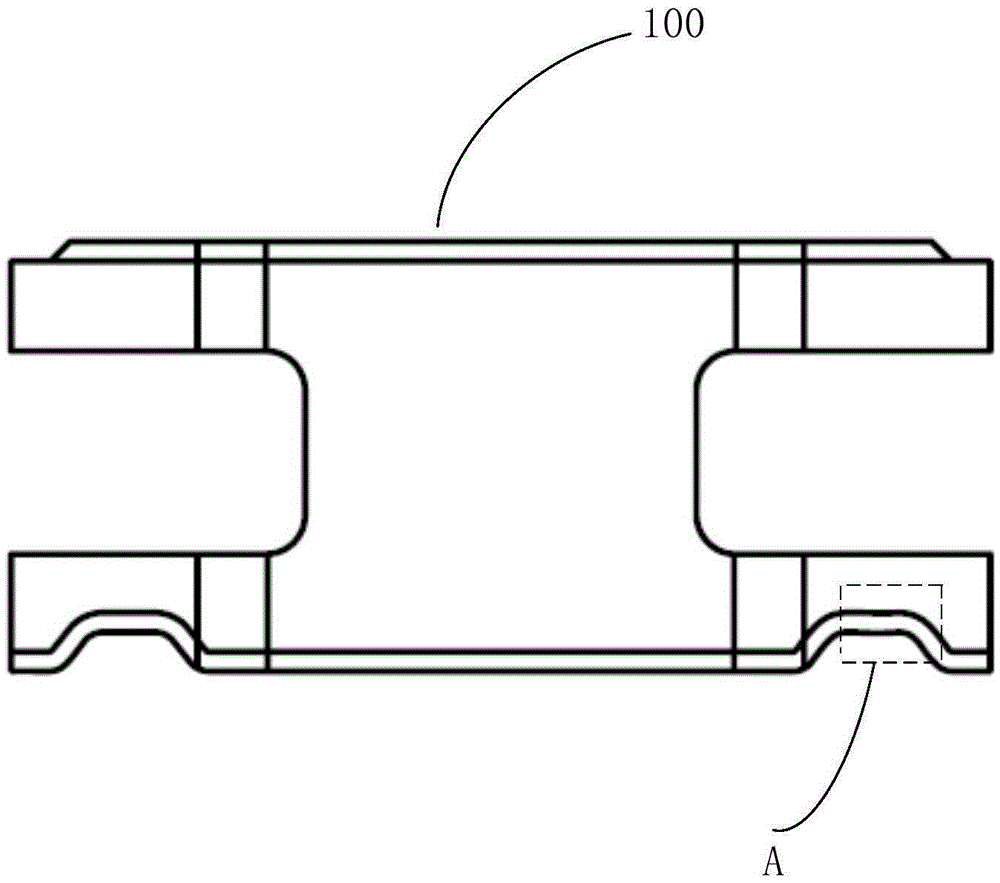

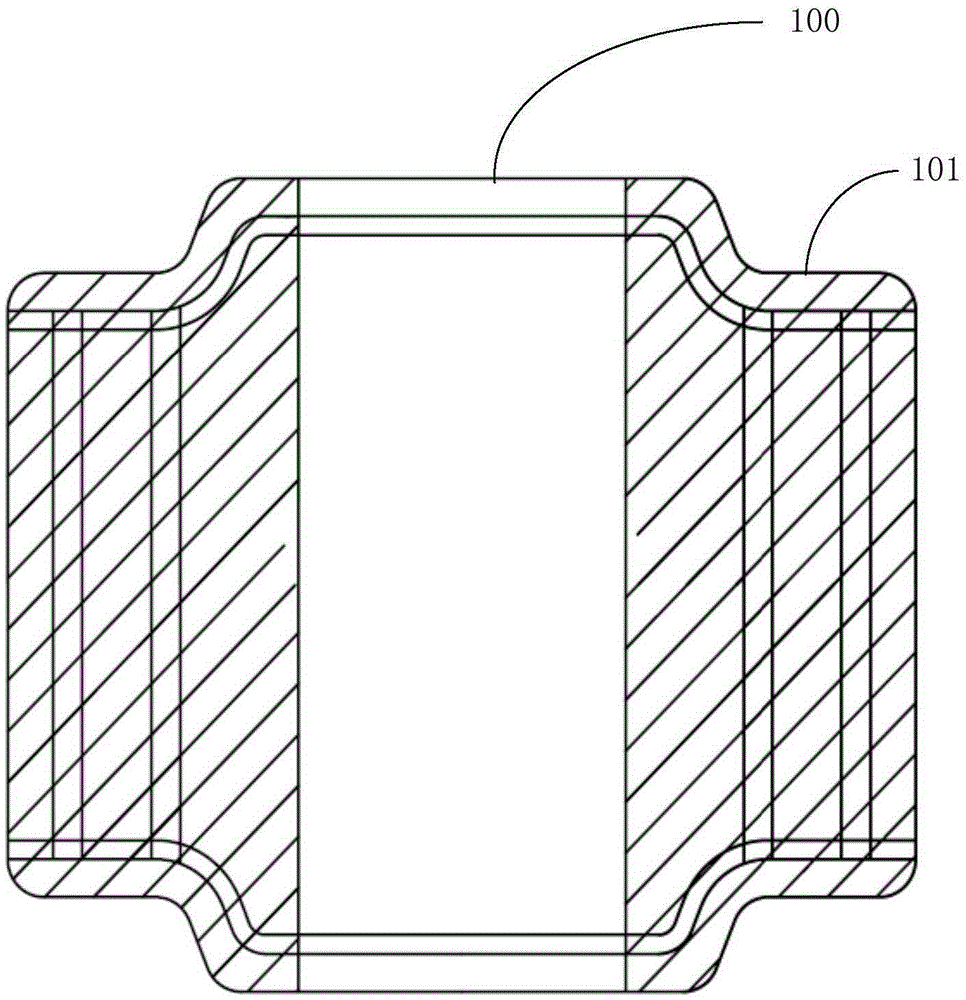

[0038] see Figure 4 , the embodiment of the present invention provides a method for preparing the metallized ferrite core, comprising the following steps:

[0039] (1) Take the ferrite core, clean and dry the ferrite core, the ferrite core is provided with an electrode region;

[0040] The cleaning operation is to remove powder and dirt on the surface of the magnetic core.

[0041] Preferably, the cleaning step specifically includes: soaking in alcohol for 5-10 minutes, then ultrasonically cleaning at 40-60°C for 10-20 minutes, then rinsing with water for 1-3 minutes, and then ultrasonically cleaning at room temperature for 10-20 minutes. 20 minutes, and finally rinse with 50-80 ℃ hot water for 1-3 minutes.

[0042] The drying operation is to remove moisture on the surface of the magnetic core, and can be performed in an oven. Preferably, the temperature of the oven is 130-170° C., and the time is 10-20 minutes.

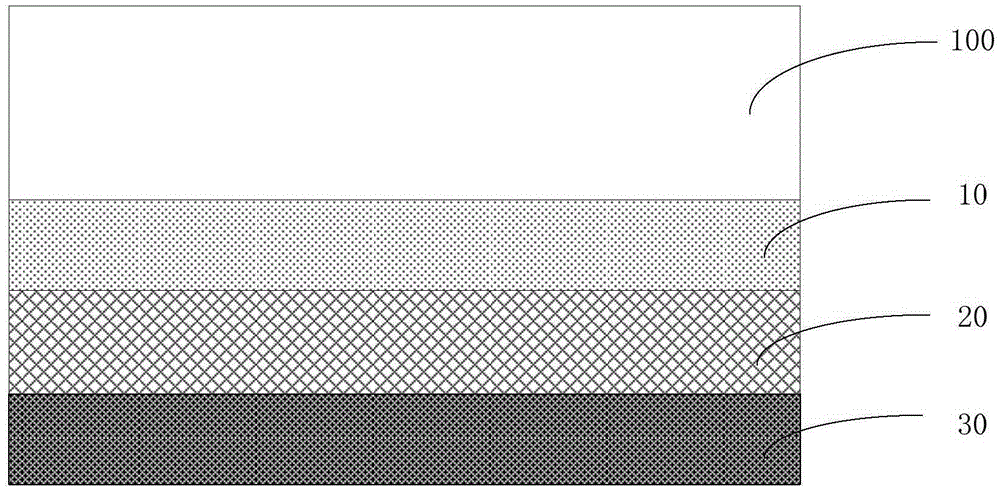

[0043] (2) Prepare a metal coating on the surface of the e...

Embodiment 1

[0053] A preparation method of the above metallized ferrite core, comprising the following steps:

[0054] (1) Take the ferrite core, clean and dry the ferrite core, the ferrite core is provided with an electrode region;

[0055] The cleaning operation is as follows: put the ferrite core in a stainless steel mesh basket, soak it in alcohol for 5 minutes, then ultrasonically clean it at 50°C for 10 minutes; then rinse it with water for 1 minute; then clean it ultrasonically at room temperature for 20 minutes; Finally, rinse with hot water for 2 minutes; blow dry with a hot blower, and then lay it flat on the grid tray to dry;

[0056] The drying operation is carried out in an oven. Specifically, spread the magnetic cores flat on the grid tray and put them into the oven. The temperature of the oven is set at 150°C for 15 minutes; it can be dried until there is no water vapor;

[0057] (2) Prepare a metal coating on the surface of the electrode region by magnetron sputtering to ...

Embodiment 2

[0063] A preparation method of the above metallized ferrite core, comprising the following steps:

[0064] (1) Take the ferrite core, clean and dry the ferrite core, the ferrite core is provided with an electrode region;

[0065] The cleaning operation is as follows: put the ferrite core in a stainless steel mesh basket, soak it in alcohol for 10 minutes, then ultrasonically clean it at 40°C for 20 minutes; then rinse it with water for 2 minutes; then clean it ultrasonically at room temperature for 15 minutes; Finally, rinse with hot water for 3 minutes; blow dry with a hot blower, and then lay it flat on the grid tray to dry;

[0066] The drying operation is carried out in an oven. Specifically, spread the magnetic cores flat on the grid tray and put them into the oven. The temperature of the oven is set at 170°C for 10 minutes; it can be dried until there is no water vapor;

[0067] (2) Prepare a metal coating on the surface of the electrode region by magnetron sputtering t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com