Edible fungus culture medium

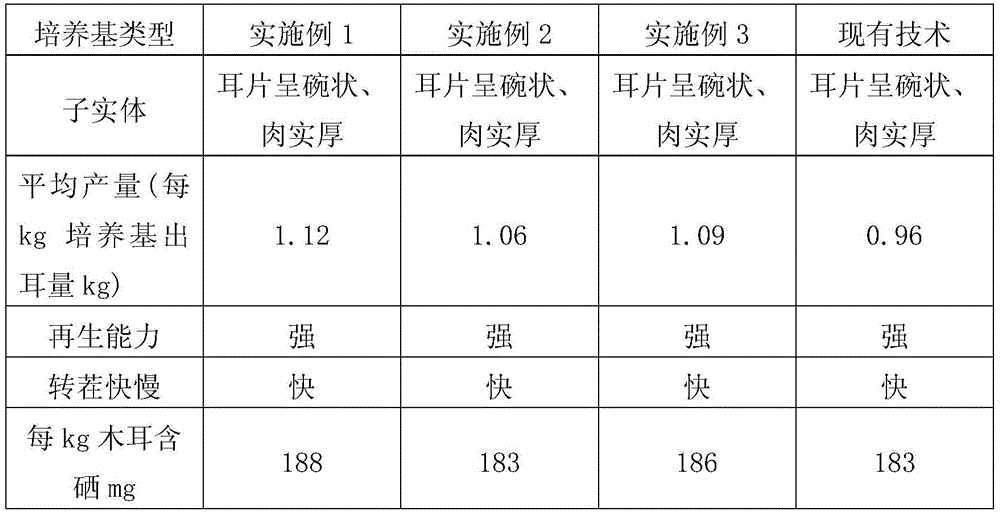

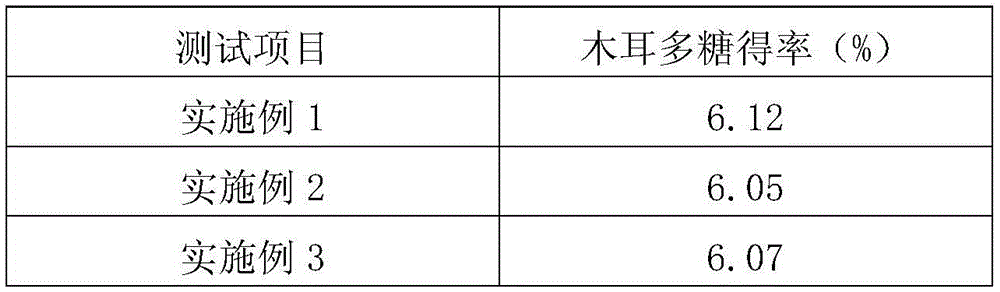

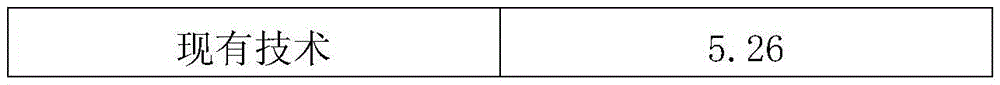

A technology for cultivating substrates and fungus, applied in calcium fertilizers, fertilizer mixtures, inorganic fertilizers, etc., can solve the problems of low yield of fungus, unsatisfactory effects, low polysaccharide content, etc., to protect fungus species and reduce production costs , the effect of inhibiting the growth of miscellaneous bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation of described fungus extract comprises the following steps:

[0029] S 1 1. Wash the fungus, crush it into powder, and pass through a 60-80 mesh sieve; S 2 , add 20 times the weight of distilled water, soak for 30 to 40 minutes; S 3 , adding a compound enzyme with a mass fraction of 0.1 to 0.3% in the solution, wherein the compound enzyme is formed by mixing cellulase: protease in a weight ratio of 1:1, adjusting the pH to 5.0 to 6.0, at 40 to 50 ° C Under enzymatic hydrolysis for 50-60 minutes; S 4 1. Warm up the enzymolysis solution to 90-100°C and keep it for 10-15min to sterilize; S 5 1. Add 10 times the weight of 40-50% ethanol, conduct ultrasonic extraction at an ultrasonic frequency of 30-40kHz, and a temperature of 50-60°C, extract for 40-50min, centrifuge, filter, and collect the fungus extract and fungus residue;

[0030] The preparation of described oat extract comprises the following steps:

[0031] S 1 1. Clean and screen the oats, then...

Embodiment 1

[0039] A fungus culture substrate, made from the following components in proportion by weight: 55 parts of mulberry twigs, 35 parts of walnut shells, 25 parts of peanut shells, 15 parts of fungus dregs, 18 parts of oat dregs, 12 parts of Luo Han Guo dregs, 25 parts of bamboo leaf residue, 3 parts of lime, 2 parts of gypsum, 12 parts of additives. Wherein, the additive is made of the following components in proportion by weight: 22 parts of fungus extract, 15 parts of oat extract, 12 parts of Luo Han Guo extract, 6 parts of bamboo leaf extract, 7 parts of chrysanthemum extract , 2 parts of sodium bentonite, 0.4 part of talcum powder, 0.2 part of magnesium sulfate, 0.3 part of calcium sulfate, 0.2 part of zinc sulfate, 0.02 part of sodium selenite, and 0.3 part of potassium dihydrogen phosphate.

Embodiment 2

[0041] A fungus culture substrate, made of the following components in proportion by weight: 50 parts of mulberry twigs, 30 parts of walnut shells, 20 parts of peanut shells, 10 parts of fungus dregs, 15 parts of oat dregs, 10 parts of Luo Han Guo dregs, 20 parts of bamboo leaf residue, 2 parts of lime, 1 part of gypsum, and 10 parts of additives. Wherein, the additive is made of the following components in proportion by weight: 20 parts of fungus extract, 10 parts of oat extract, 10 parts of Luo Han Guo extract, 5 parts of bamboo leaf extract, 6 parts of chrysanthemum extract 1 part of sodium bentonite, 0.3 part of talcum powder, 0.1 part of magnesium sulfate, 0.2 part of calcium sulfate, 0.1 part of zinc sulfate, 0.01 part of sodium selenite, and 0.2 part of potassium dihydrogen phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com