Hot melt adhesive film for rubber and metal adhesion and preparation method of hot melt adhesive film

A hot-melt adhesive film, rubber metal technology, applied in adhesives, polymer adhesive additives, film/sheet adhesives, etc., can solve the problem of difficult breakthroughs in material bonding, complex processes, liquid adhesive solvents, etc. Solve problems such as volatility and toxicity, achieve good bonding strength, simple preparation process, and strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

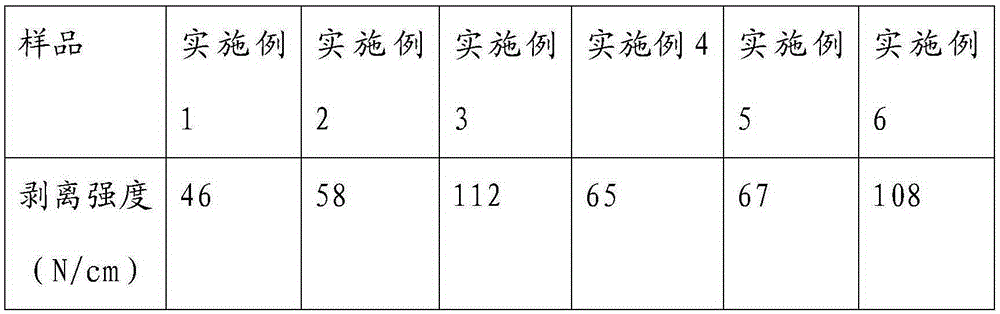

Embodiment 1

[0028] Step 1, get 100 parts by mass of EVA resin, wherein the melting point of EVA resin is 50°C, the melt index is 40g / 10min, add 0.01 parts by mass of 2,5-dimethyl-2,5-bis(tert-butyl peroxide Base) hexane and 5 mass parts number average molecular weight are 4500, maleic anhydride content is the polybutadiene of maleic anhydride modification of 3%, at 190 ℃ with twin-screw extrusion grafting and granulation oven dry; Step 2: Weigh 100 parts by mass of the particles produced in Step 1, add 0.5 parts by mass of DTDM and mix evenly, and prepare a film with a thickness of 0.3 mm by casting method. The specific test results are shown in Table 1.

Embodiment 2

[0030] Step 1, take 100 parts by mass of POE resin, wherein the melting point of POE resin is 60°C, the melt index is 15g / 10min, add 0.2 parts by mass of 2,5-dimethyl-2,5-bis(tert-butyl peroxide Base) hexane and 5 mass parts number average molecular weight are 7500, maleic anhydride content is the polybutadiene of maleic anhydride modification of 20%, at 190 ℃ with twin-screw extrusion grafting and granulation oven dry; Step 2: Weigh 100 parts by mass of the particles produced in Step 1, add 5 parts by mass of TMTD and mix evenly, and prepare a film with a thickness of 0.3 mm by casting method. The specific test results are shown in Table 1.

Embodiment 3

[0032] Step 1, get 100 parts by mass of EVA resin, wherein the melting point of EVA resin is 105 ° C, the melt index is 2g / 10min, add 0.05 parts by mass of dicumyl peroxide and 0.5 parts by mass of the number average molecular weight is 9900, Malay The acid anhydride content is the maleic anhydride modified polybutadiene of 6%, under 190 ℃, use twin-screw extrusion grafting and granulation drying; Step 2, weigh 100 mass parts step 1 made particles, add 0.5 Parts by mass of DTDM were uniformly mixed, and a film with a thickness of 0.3 mm was prepared by a casting method. The specific test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com