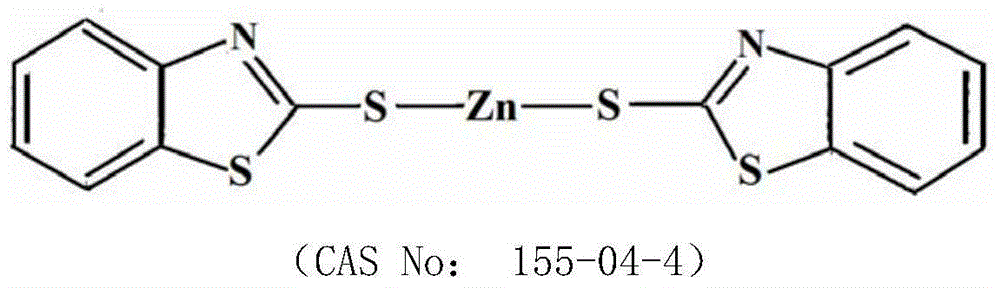

Composition containing zinc 2-mercaptobenzothiazole and sterol demethylation inhibitors (DMIs) bactericide, and preparation and application thereof

A technology of composition and fungicide, applied in the field of agriculture, can solve problems such as side effects and achieve good fungicidal activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

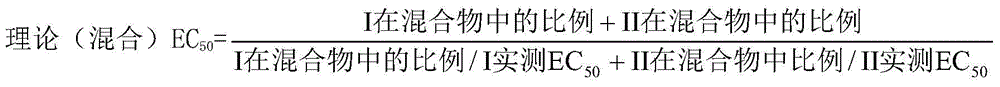

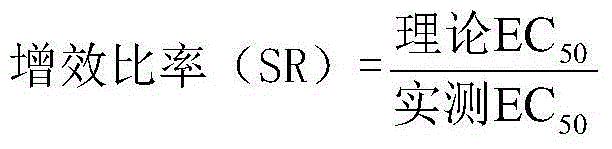

Method used

Image

Examples

Embodiment 1

[0097] 45% active compound (40.0% 2-mercaptobenzothiazole zinc and 5.0% difenoconazole composition), fatty alcohol polyoxyethylene ether sulfate 2.0%, phenolsulfonic acid condensate sodium salt 2.0%, methyl Sodium naphthalenesulfonate formaldehyde condensate 3.0%, sodium starch octenyl succinate 1.0%, glycerol 2.0%, butyl p-hydroxybenzoate 0.2%, silicone defoamer 0.1%, deionized water to 100% , put it into a high-shear homogeneous emulsifier for high-speed shearing for 25 minutes, then pump it into a sand mill for sanding for 90 minutes, and filter to obtain a 45% active compound suspension.

Embodiment 2

[0099] 32% active compound (30.0% zinc 2-mercaptobenzothiazole and 2.0% diniconazole combination), tallow ethoxylated ammonium salt 2.0%, sodium methylnaphthalenesulfonate formaldehyde condensate 4.0%, xanthan gum 0.2%, glycerin 2.0%, butyl p-hydroxybenzoate 0.2%, silicone defoamer 0.2%, deionized water to make up to 100%, put it into a high-shear homogeneous emulsifier for 25 minutes at high speed, Then pump it into a sand mill for sand grinding for 90 minutes, and filter to obtain a 32% active compound suspension.

Embodiment 3

[0101]30% active compound (10.0% 2-mercaptobenzothiazole zinc and 20.0% epoxiconazole composition), 2.0% alkylnaphthalene sulfonate, 1.0% fatty alcohol polyoxyethylene ether sulfate, polymer polycarboxylic acid Salt 2.0%, sodium lignosulfonate 2.0%, sodium starch octenyl succinate 2.0%, triphenyl phosphite 0.5%, ethylene glycol 2.0%, silicone defoamer 0.1%, deionized water to 100 %, put it into a high-shear homogeneous emulsifier for high-speed shearing for 25 minutes, then pump it into a sand mill for sanding for 90 minutes, and filter to obtain a 30% active compound suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com