Drag-reduction agent slurry and preparation method thereof

A technology of drag reducer and slurry, applied in mechanical equipment, gas/liquid distribution and storage, pipeline system, etc., can solve problems such as suffocation, cumbersome operation, and large liquid nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

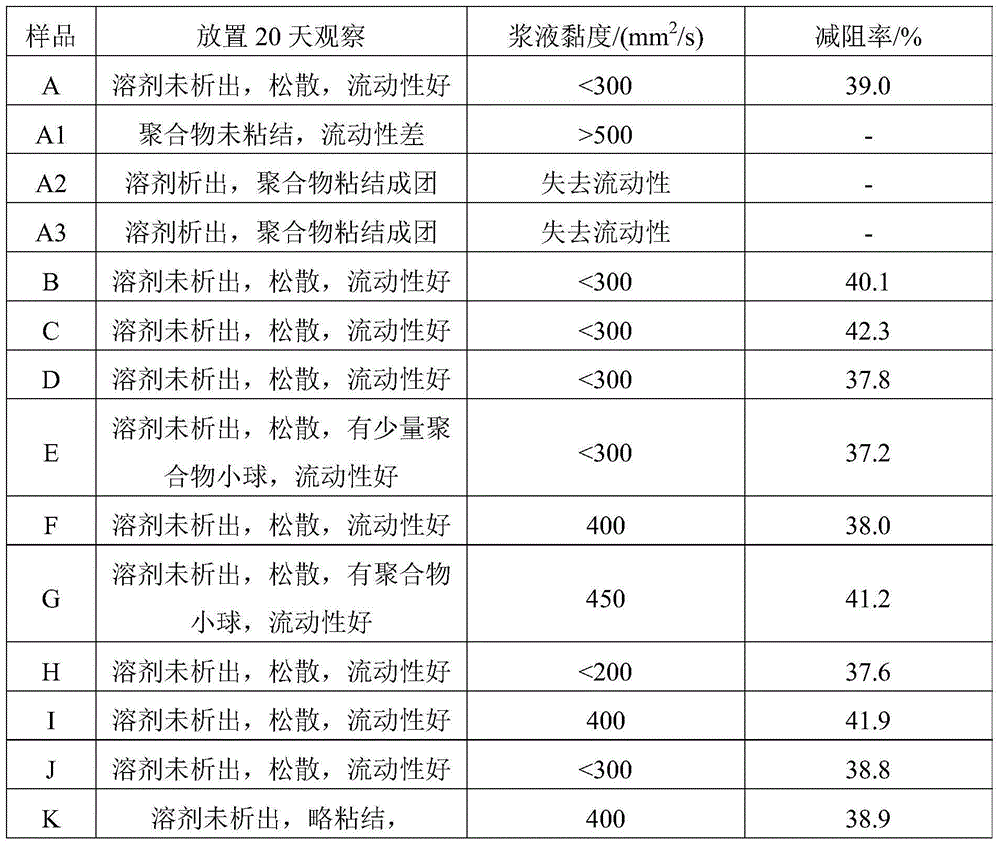

[0013] According to the present invention, the preparation method of the drag reducer slurry includes performing slurry polymerization on α-olefin monomers in silicone oil to obtain a drag reducer polymer suspension, wherein the method also includes: the obtained drag reducer Carry out solid-liquid separation of the agent polymer suspension, separate the lower silicone oil phase, and mix the upper solid elastomer phase with the release agent, surfactant and alcohol solvent evenly, and the surfactant is an anionic-nonionic surfactant .

[0014] Preferably, the anionic-nonionic surfactant is selected from the group consisting of alkylphenol polyoxyethylene ether phosphate, alkylphenol polyoxyethylene ether sulfonate, fatty alcohol polyoxyethylene phosphate, fatty alcohol polyoxyethylene One or more of sulfonate and fatty alcohol polyoxyethylene sulfate. Wherein, the number of carbon atoms of the alkyl group in the alkylphenol polyoxyethylene ether phosphate and the alkylphenol ...

Embodiment 1

[0051] This example is used to illustrate the preparation of the drag reducer slurry provided by the present invention.

[0052] The polymerization catalyst used is prepared by the following method: 2.0 grams of ethoxymagnesium microparticle carrier (particle diameter is 40-50 microns), toluene 30ml are added in the reaction bottle and dispersed evenly, the temperature is reduced to -10 ℃, add 10ml (6.0mol )TiCl 4 , stay for 0.5 hours, warm up to 80°C, add 0.6ml (0.39mol) diisobutyl phthalate, heat up to 110°C for 2 hours, settle, filter, heat wash twice with toluene (20ml each time), twice Load titanium, add 5ml (3.0mmol) TiCl 4 React with 30ml of toluene for 1 hour, settle, filter, wash with hexane four times, and dry at 72°C to obtain a catalyst solid component. The mass percent content of titanium in the catalyst is 2.87%.

[0053] Mix 35 g of 1-octene refined with molecular sieves (purchased from ACROS Reagent Company) with 65 g of simethicone oil refined with molecula...

Embodiment 2

[0055] This example is used to illustrate the preparation of the drag reducer slurry provided by the present invention.

[0056] The drag reducer slurry was prepared according to the method of Example 1, the difference was that after the polymerization reaction, 3.0 g of zinc stearate was added to the upper solid elastomer phase, and the emulsifier was mixed evenly, and the surfactant nonylphenol was added 2.0 g of oxyethylene ether (21) sulfonate, 30 g of n-octanol, mix well, pour into a stoppered jar and let stand for observation. Get sample B. The storage stability, fluidity and drag reduction rate are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com