Hyperbranched anti-crease finishing agent as well as preparation method and application thereof

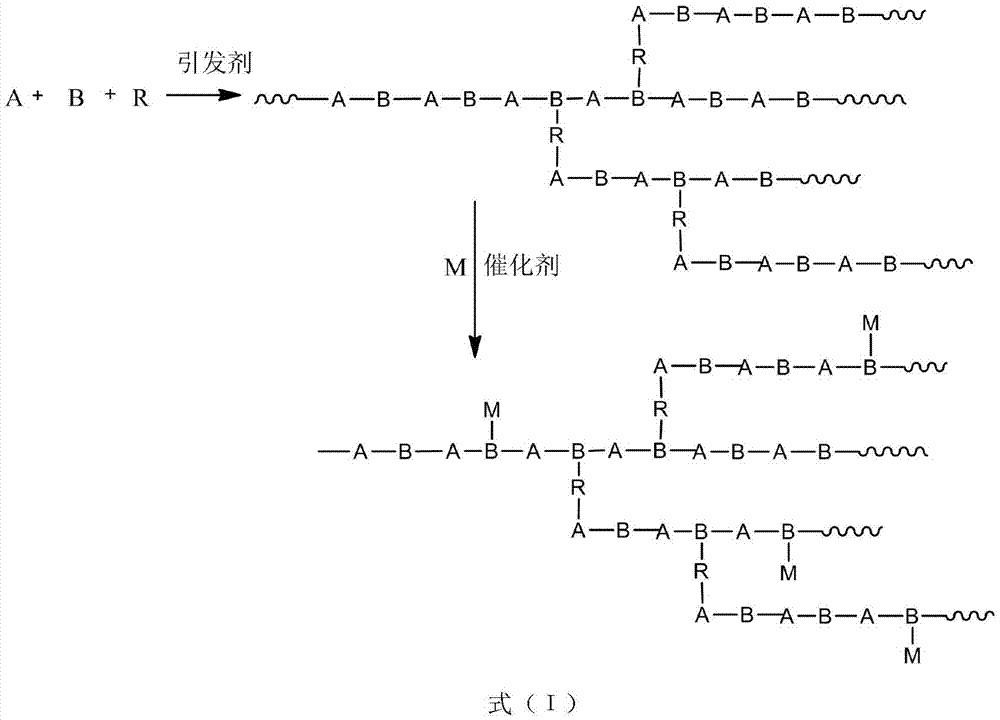

A technology of anti-wrinkle finishing agent and catalyst, which is applied in fiber treatment, textiles and papermaking, and fibers that affect crease behavior. It can solve the problems of fabric strength loss, release of formaldehyde, complex synthesis process, etc., and achieve product composition and structure controllable, Increased deformation recovery ability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Dissolve 10.4g of styrene, 9.81g of maleic anhydride and 0.6g of p-vinylbenzylmercaptan in 132g of acetone, under the trigger of 0.2g of azobisisobutyronitrile, keep the reaction at 70°C for 4h, and prepare a content of 15 % polymer solution; 0.86g p-toluenesulfonic acid is added to the polymer solution obtained in the first step, and the temperature is controlled at 80° C., and the aqueous solution of 4-ethyl sulfate sulfone aniline (14.42 g) is added dropwise Put into the reactor, keep the reaction temperature for 8 hours, cool to room temperature, distill the obtained solution under reduced pressure, and remove the organic solvent to obtain the wrinkle-resistant finishing agent.

Embodiment 2

[0036] Dissolve 10.42g of styrene, 17.41g of aconitic acid and 1.4g of p-vinylbenzylmercaptan in 140g of acetone, and under the trigger of 0.28g of azobisisobutyronitrile, keep the reaction at 80°C for 6h, and prepare a content of 20 % polymer solution; 0.87g p-toluenesulfonic acid is added to the polymer solution obtained in the first step, and the temperature is controlled at 80°C, and N-methylolacrylamide (5.05g) solution is added dropwise to In the reactor, keep the reaction temperature for 8 hours, cool to room temperature, distill the obtained solution under reduced pressure, and remove the organic solvent to obtain the anti-wrinkle finishing agent.

Embodiment 3

[0038] Dissolve 10.25g of n-butyl acrylate, 13.01g of itaconic acid and 2.33g of p-chloromethylstyrene in 116g of DMF, and under the trigger of 0.2g of benzoyl peroxide, keep warm at 70°C for 6h to prepare a content of 20 % polymer solution; 0.65g p-toluenesulfonic acid is added to the polymer solution obtained in the first step, the temperature is controlled at 90°C, and the m-sulfone ethylsulfone aniline (7.21g) solution is added dropwise Put into the reactor, keep the reaction temperature for 8 hours, cool to room temperature, distill the obtained solution under reduced pressure, and remove the organic solvent to obtain the wrinkle-resistant finishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com