SOI pressure-sensitive chip based on sacrificial layer technology, and manufacturing method thereof

A technology of sensitive chips and sacrificial layers, which is applied in the direction of microstructure technology, manufacturing microstructure devices, and techniques for producing decorative surface effects, etc. It can solve the problems of poor performance such as sensor repeatability and hysteresis, and achieve repeatability and stability. Good performance, high sensitivity, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below by accompanying drawing:

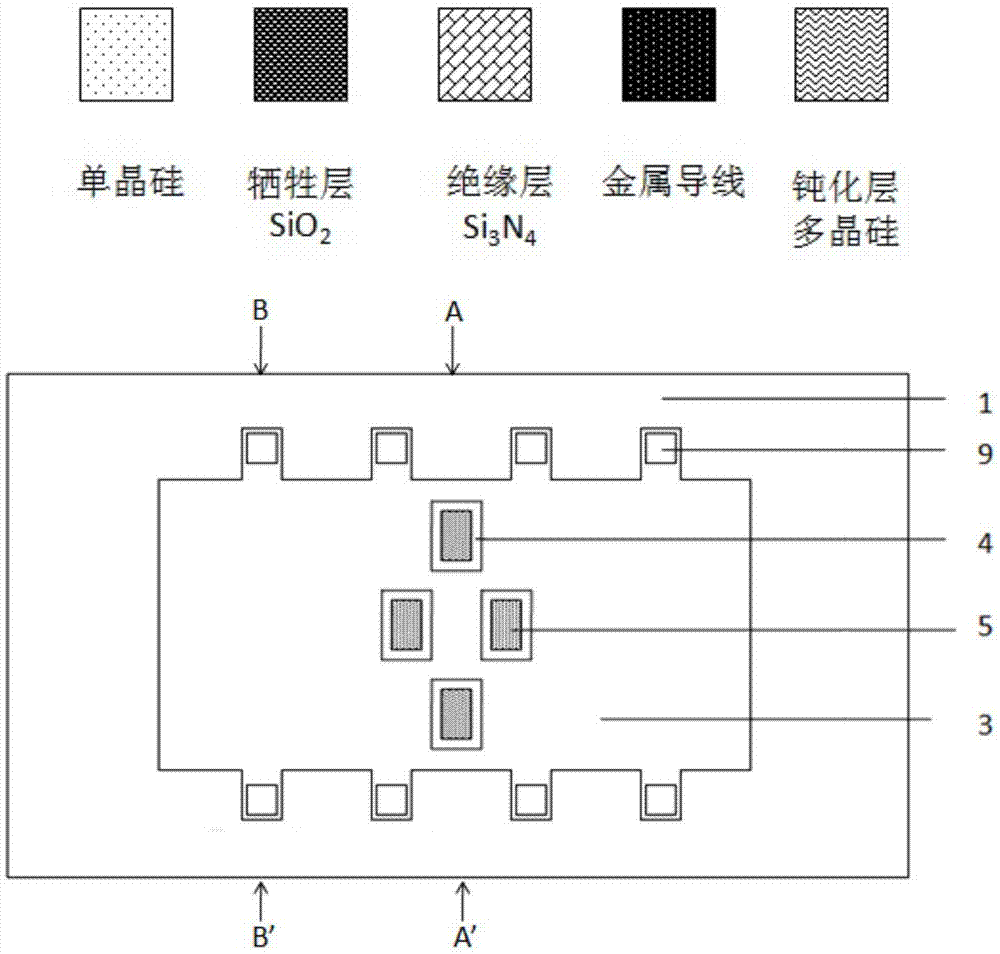

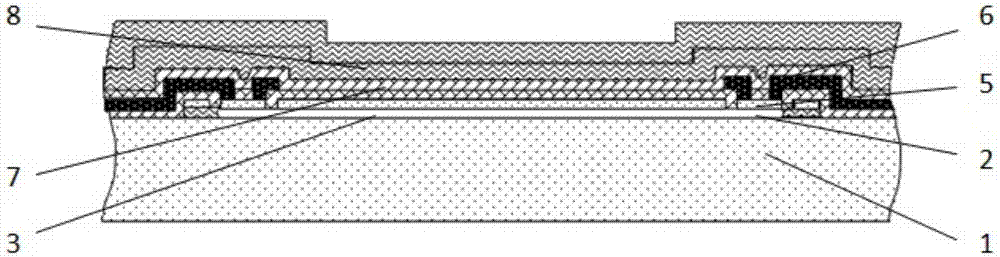

[0044] The invention provides a SOI pressure-sensitive chip based on sacrificial layer technology, such as figure 1 and figure 2 As shown, it is characterized in that: the chip is made of a single crystal silicon film (SOI) material on an insulating layer, including a single crystal silicon substrate 1 of SOI, and an SOI silicon dioxide insulating layer is used as a sacrificial layer above the single crystal silicon substrate 1 The cavity 2 is formed by layers, the top of the cavity 2 is a single crystal silicon film 3, and the isolation groove 4 is etched on the single crystal silicon film 3 to form four strain resistors 5 and their metal wires 6. The silicon nitride insulating protection layer 7 located above and below the metal wire 6 and the outermost polysilicon structure layer 8 and the single crystal silicon film 3 together form a sensitive chip pressure-sensitive film, and eight s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com