Lithium ion battery cathode material of which nano particles embedded into carbon nanosheet and preparation method of lithium ion battery cathode material

A lithium-ion battery and carbon nanosheet technology, applied in the field of electrochemistry, can solve the problems of poor cycle performance of nanoparticles, and achieve the effects of good cycle ability, high capacity and good cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

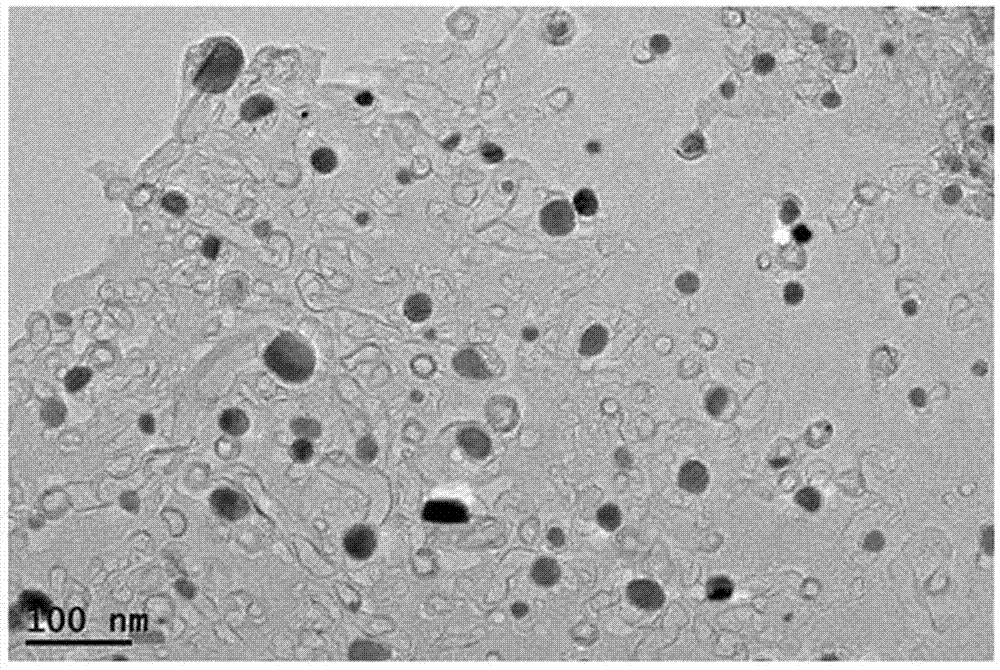

[0026] The preparation method of nano-metal tin particles embedded in carbon nano-sheet lithium ion battery anode material includes the following steps:

[0027] (1) Precursor preparation: Take citric acid as the carbon source, commercial micron metal tin as the particle source, and sodium chloride as the template, weigh 0.6 g commercial micron metal tin, 3 g citric acid and 30 g sodium chloride , Put into a ball mill tank, add 10 mL of distilled water, ball mill at a speed of 500 rpm for 20 hours, put the obtained mixture in an oven, dry at 80°C, and put it in a tube furnace.

[0028] (2) Precursor pyrolysis treatment: The prepared precursor samples are evenly spread on the bottom of the burning boat, and the burning boat is placed in the constant temperature zone of the tube furnace. Nitrogen gas is first introduced for 30 minutes to remove the air in the tube furnace, and then The mixed gas of argon and hydrogen is programmed to heat up to 750°C at 2°C / min for carbonization, kep...

Embodiment 2

[0031] Similar to Example 1, the difference is that the method for preparing the precursor in step (1) of this example is: using sodium citrate as a carbon source, commercial micron-sized metal tin as a particle source, and sodium chloride as a template. Take 0.6g of commercial micron metal tin, 3g of sodium citrate and 30g of sodium chloride, put them into a ball mill tank, add 10mL of distilled water, ball mill at 500rpm for 20h, put the resulting mixture in an oven, and dry at 80°C Put it in a tube furnace.

Embodiment 3

[0033] Similar to Example 1, the difference is that the method for preparing the precursor in step (1) of this example is as follows: sodium citrate is used as a carbon source, commercial micron-sized silicon powder is used as a particle source, and sodium chloride is used as a template. Take 0.6g of commercial micron silicon powder, 3g of sodium citrate and 30g of sodium chloride, put them in a ball milling tank, add 10mL of distilled water, and ball mill at 500rpm for 20h. Put the resulting mixture in an oven and dry at 80°C. Put it in a tube furnace.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com