Photoreactor for wastewater treatment

A photoreactor and wastewater treatment technology, which is applied in the field of photoreactor preparation, can solve the problems of troublesome application, high cost, and difficult recovery of photocatalysts, and achieve the effect of low cost and adjustable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Select a glass mirror with a size of 100×30cm and a hollow glass bead with a diameter of 2.5cm and a through hole with a diameter of 2mm inside, wash and dry with acetone, ethanol, and deionized water in sequence; brush the surface of the dried glass mirror with a certain concentration of Hydrofluoric acid buffer solution and glass beads are soaked in hydrofluoric acid buffer solution for etching treatment. The etching time is 3 hours; the etched glass mirror surface and glass beads are washed repeatedly with deionized water until PH = 7. Let it dry naturally for later use.

[0028] Coat a layer of titanium dioxide transparent sol precursor on the treated glass mirror, place it vertically until it dries naturally, repeat the above-mentioned coating operation 5 times, put it into a calcining kiln after drying at 80 °C and slowly heat up to 500 °C Calcined at ℃ for 2h, cooled naturally and stored for later use.

[0029] Soak the treated glass spheres in the prepared tita...

Embodiment 2

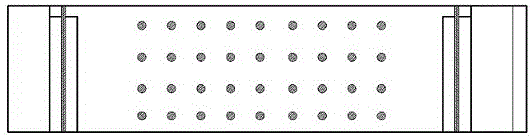

[0033] The arrangement of the glass beads in the photoreactor in Example 1 was changed to lay flat on the bottom of the reactor, the filling density was 4 per 10 cm, and the filling height was 2 layers. The specific arrangement is as Figure 4 shown.

Embodiment 3

[0035] Change the arrangement of the glass beads in the photoreactor in Example 1 to use a wooden stick with a diameter of 1mm to string the glass beads, with an interval of 1cm between the glass beads; They are arranged in a triangle with a distance of 1 cm from each other. The specific arrangement is as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com