Acetal preparation method

A technology of acetal and acetaldehyde, which is applied in the field of synthesis of organic compounds, can solve the problems of acid instability, unfavorable large-scale production, low output, etc., achieve lower pressure resistance performance requirements, be conducive to sustainable development, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

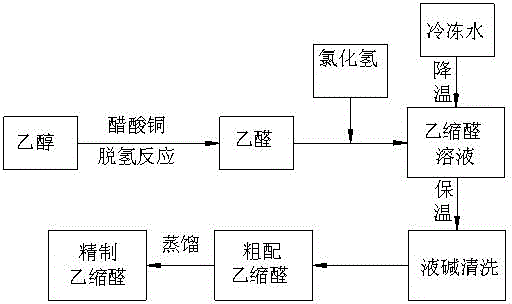

[0015] Such as figure 1 Shown, a kind of preparation method of acetal of the present invention comprises the following steps:

[0016] Step 1, adding a copper-based salt to ethanol, the copper-based salt being copper acetate, causing dehydrogenation of ethanol to produce acetaldehyde;

[0017] Step 2: Add the prepared acetaldehyde into the ceramic reaction pot, and add hydrogen chloride at the same time to make the acetaldehyde polymerize to form acetal, and the polymerization reaction is to keep the temperature at 30 The reaction takes place between four hours and thirty-five degrees Celsius.

[0018] The detailed steps are as follows:

[0019] One, the preparation of acetaldehyde

[0020] Weigh 1 kg of ethanol, add 500 g of fully ground copper acetate solid (the copper acetate powder is 20-40 mesh), and produce acetaldehyde through dehydrogenation reaction.

[0021] 2. Acetaldehyde undergoes polymerization reaction to produce acetal

[0022] Take the acetaldehyde prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com