Preparation method and application of vegetable oil polyol

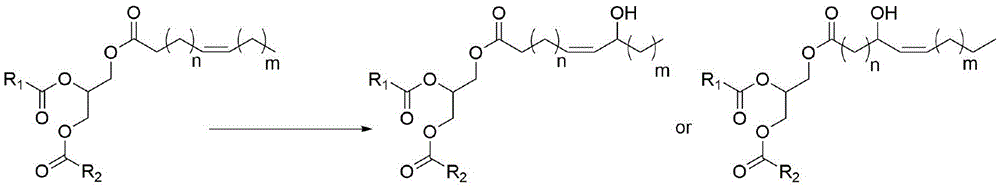

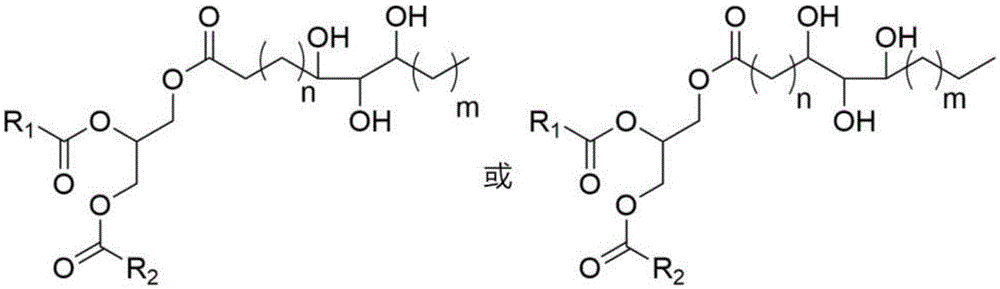

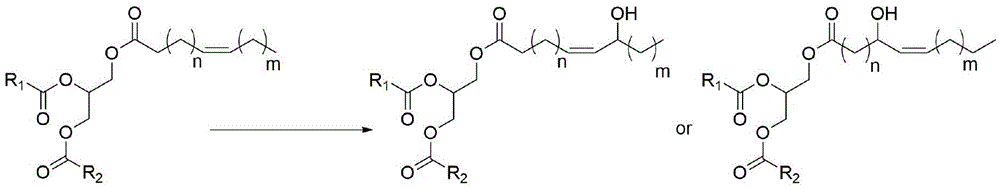

A vegetable oil polyol and vegetable oil technology, which is applied in the preparation of organic compounds, carboxylic acid ester preparation, chemical instruments and methods, etc., can solve the problems of low hydroxyl value and low quality, achieve high hydroxyl value, reduce the occurrence of side reactions, The effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Dissolve 100g soybean oil in 670mL ethyl acetate, add 18.9g selenium dioxide, mix well, stir and react at 40℃ for 30h, then add 335mLNa 2 CO 3 Cool the saturated aqueous solution to cool down, then add appropriate amount of Na 2 SO 3 Remove excess oxidant, then separate the organic phase, wash with saturated sodium chloride aqueous solution three times, and dry with anhydrous magnesium sulfate to obtain allyl oxidized vegetable oil; then combine the oxidized vegetable oil with epoxy-hydroxylation reagent (98 % Formic acid 186.8g, 30% hydrogen peroxide 450.9g, 98% sulfuric acid 1.7g, ethylenediaminetetraacetic acid disodium 4.2g) were simultaneously pumped into the microchannel modular reaction device (the microstructure reactor model is sandwichreactorHC), and the flow rates were respectively 0.8mL / min, 4.9mL / min, keep at 70℃ and normal pressure for 6.5min, finally collect the organic phase in the product, wash with 5% sodium carbonate aqueous solution to neutrality, and d...

Embodiment 2

[0045] Dissolve 100g of peanut oil in 670mL of tetrahydrofuran, add 17.5g of selenium dioxide, mix well, stir and react at 45℃ for 35h, then add 335mL of Na 2 CO 3 Cool the saturated aqueous solution to cool down, then add appropriate amount of Na 2 SO 3 Remove excess oxidant, then separate the organic phase, wash with saturated sodium chloride aqueous solution three times, and dry with anhydrous magnesium sulfate to obtain allyl oxidized vegetable oil; then combine the oxidized vegetable oil with epoxy-hydroxylation reagent (98 169.0g of% formic acid, 407.9g of 30% hydrogen peroxide, 1.8g of 98% sulfuric acid, 6.7g of disodium ethylenediaminetetraacetic acid) were pumped into the microchannel modular reaction device at the same time (the microstructure reactor used homemade Hastelloy microchannel reaction The flow rate is 0.3mL / min, 1.9mL / min, and kept at 60℃ and normal pressure for 9min. Finally, the organic phase in the product is collected, and the 5% sodium carbonate aqueous...

Embodiment 3

[0047] Dissolve 100g cottonseed oil in 670mL ethyl acetate, add 89.6g tert-butanol peroxide, mix well, stir and react at 50℃ for 40h, then add 335mLNa 2 CO 3 Cool the saturated aqueous solution to cool down, then add appropriate amount of Na 2 SO 3 Remove excess oxidant, then separate the organic phase, wash with saturated sodium chloride aqueous solution three times, and dry with anhydrous magnesium sulfate to obtain allyl oxidized vegetable oil; then combine the oxidized vegetable oil with epoxy-hydroxylation reagent (98 % Formic acid 210.2g, 30% hydrogen peroxide 507.3g, 98% sulfuric acid 4.0g, ethylenediaminetetraacetic acid disodium 18.5g) were simultaneously pumped into the microchannel modular reaction device (the microstructure reactor model is sandwichreactorHC), and the flow rates were respectively 0.5mL / min, 3.2mL / min, keep at 90℃ and normal pressure for 10min, finally collect the organic phase in the product, wash with 5% sodium carbonate aqueous solution to neutralit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com