Method for preparing monomers of different polymerization degrees of fully deacetylated chitosan oligosaccharide capable of being detected on line

A technology of acetylated chitosan oligosaccharide and degree of polymerization is applied in the field of preparation of monomers with different degrees of polymerization of fully deacetylated chitosan oligosaccharide, which can solve the problems such as inability to realize continuous production, inability to guarantee accuracy, and influence on the experimental process, etc. The effect of convenient and flexible time, reduction of manpower and material resources, and fast flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take 10 g of fully deacetylated chitosan oligosaccharide (molecular weight <1000) and dissolve it in 150 ml of deionized water, add 4 times the volume of ethanol for precipitation, filter after precipitation, and freeze-dry the filtrate to obtain a powder after concentration.

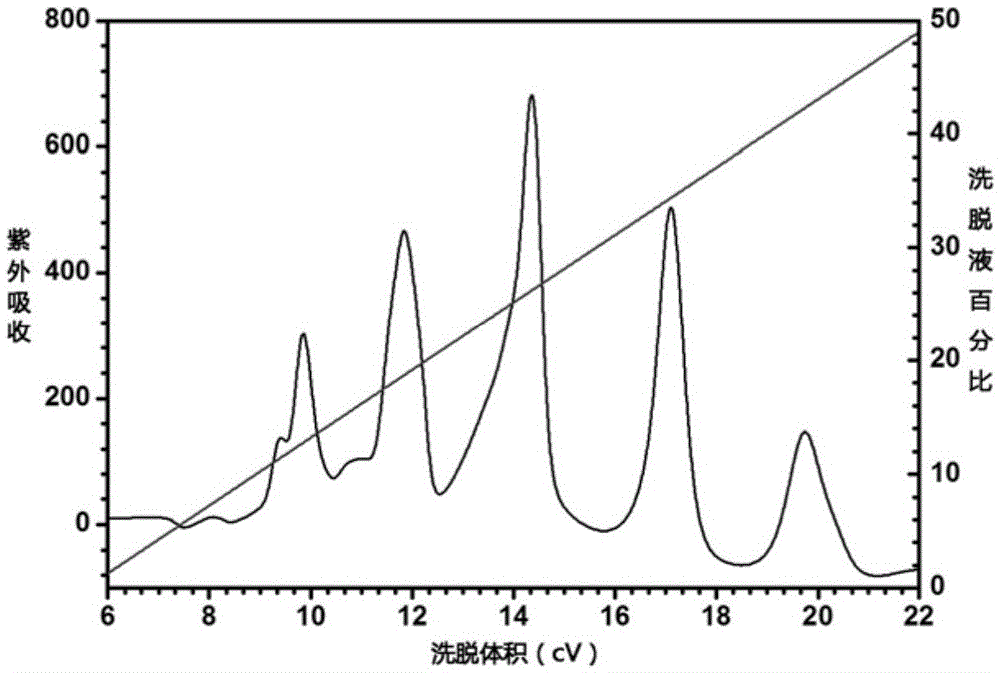

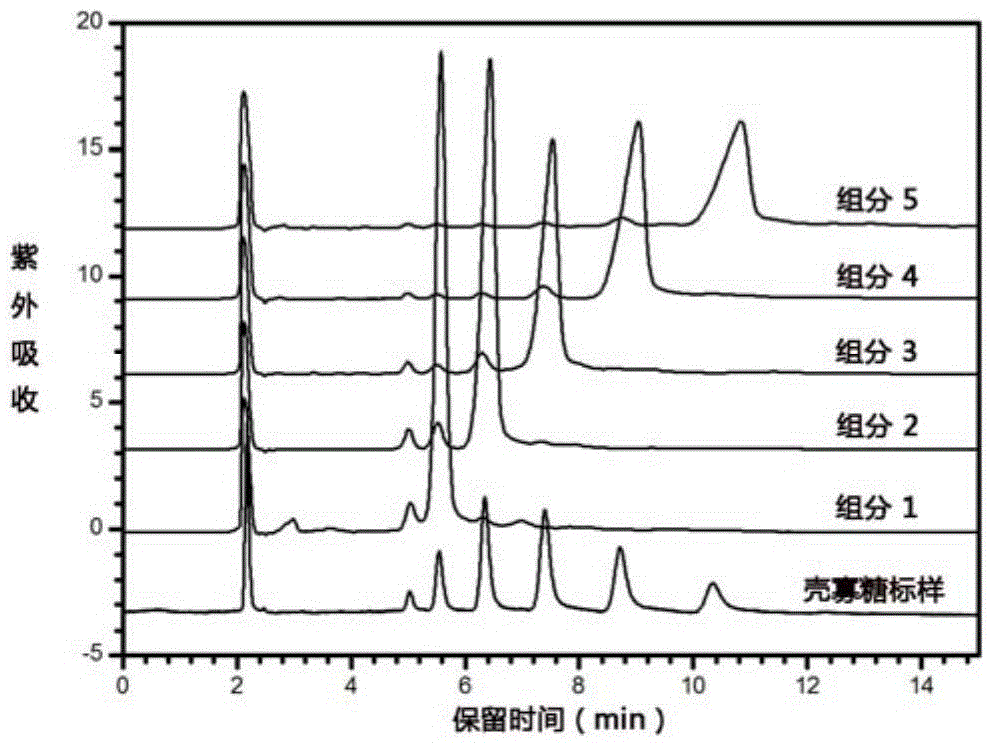

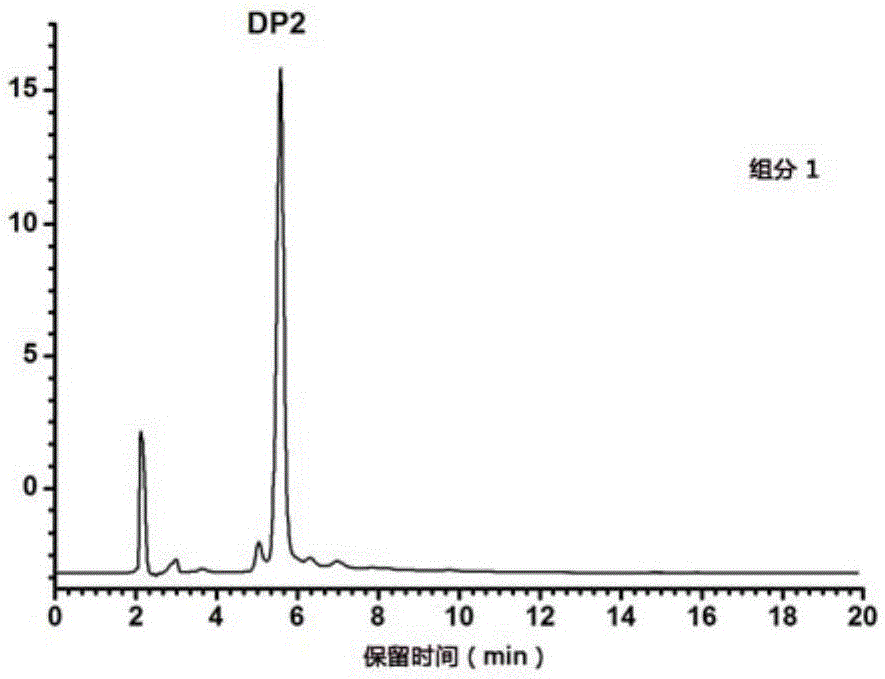

[0033] After dissolving the obtained powder with acetic acid buffer solution with a pH of 4, after filtering through a microporous membrane with a pore size of 0.45 μm, the cation exchange column SP Sepharose HP was used for separation on the AKTAavant150 protein separation system, with 1M concentration of NaCl The solution is eluted at a flow rate of 2mL / min, and the components are collected according to the peak by detecting the ultraviolet absorption at 190nm online: the peak value is >100mAU, and the collection volume of each collection tube is 2ml. The specific elution positions are 9.84cV, 11.83cV, 14.36cV, 17.10cV and 19.74cV according to the combination of the components near the peak tip ...

Embodiment 2

[0037] Take 15g of fully deacetylated chitosan oligosaccharide (molecular weight<1000) and dissolve it in 150ml of deionized water, add 5 times the volume of ethanol for precipitation, filter after precipitation, and freeze-dry the filtrate to obtain a powder after concentration.

[0038] After dissolving the obtained powder with an acetic acid buffer solution with a pH of 5, and filtering through a microporous membrane with a pore size of 0.45 μm, the cation-exchange chromatography column SP Sepharose HP was used for separation on the AKTAavant150 protein separation system. The solution was eluted at a flow rate of 5mL / min, and the components were collected according to the peak by detecting the ultraviolet absorption at 200nm online: the peak value was >120mAU, and the collection volume of each collection tube was 1.5ml. According to the graph, the components near the peak tip were combined, and the specific elution positions were 10.12cV, 12.77cV, 15.41cV, 18.36cV and 21.55c...

Embodiment 3

[0042] Take 20 g of fully deacetylated chitosan oligosaccharide (molecular weight <1000) and dissolve it in 200 ml of deionized water, add 3 times the volume of ethanol for precipitation, filter after precipitation, and freeze-dry the filtrate to obtain a powder after concentration.

[0043] After the obtained powder was dissolved in acetic acid buffer solution with a pH of 6, filtered through a microporous membrane with a pore size of 0.45 μm, and separated on the AKTAavant150 protein separation system with a cation-exchange column SP SepharoseHP, with 3M concentration of NaCl The solution was eluted at a flow rate of 8mL / min, and the components were collected according to the peak by detecting the ultraviolet absorption at 220nm online: the peak value was >140mAU, and the collection volume of each collection tube was 1.0ml. The specific elution positions are 9.57cV, 11.93cV, 14.17cV, 16.32cV and 19.03cV respectively according to the components near the peak tip combined in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com