Salt recrystallization inhibitor for oil and gas well and preparation method of salt recrystallization inhibitor

An inhibitor and recrystallization technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as rock loss, stuck drilling, and reduced well diameter, and achieve increased solubility, prevention of salt sticking, and prevention of pump sticking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

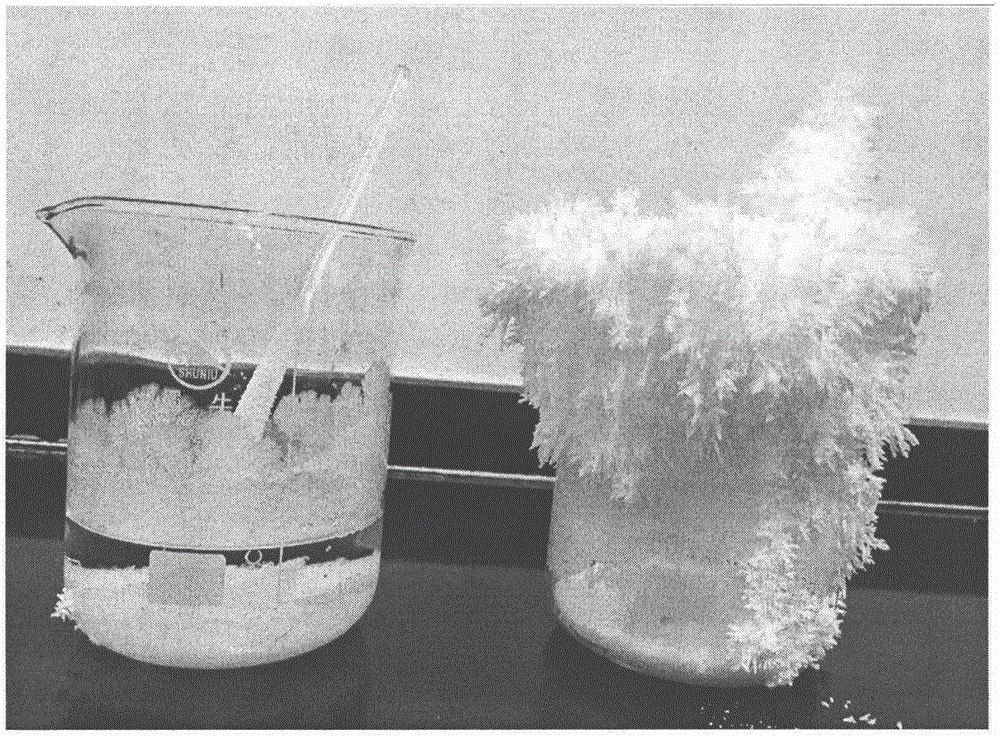

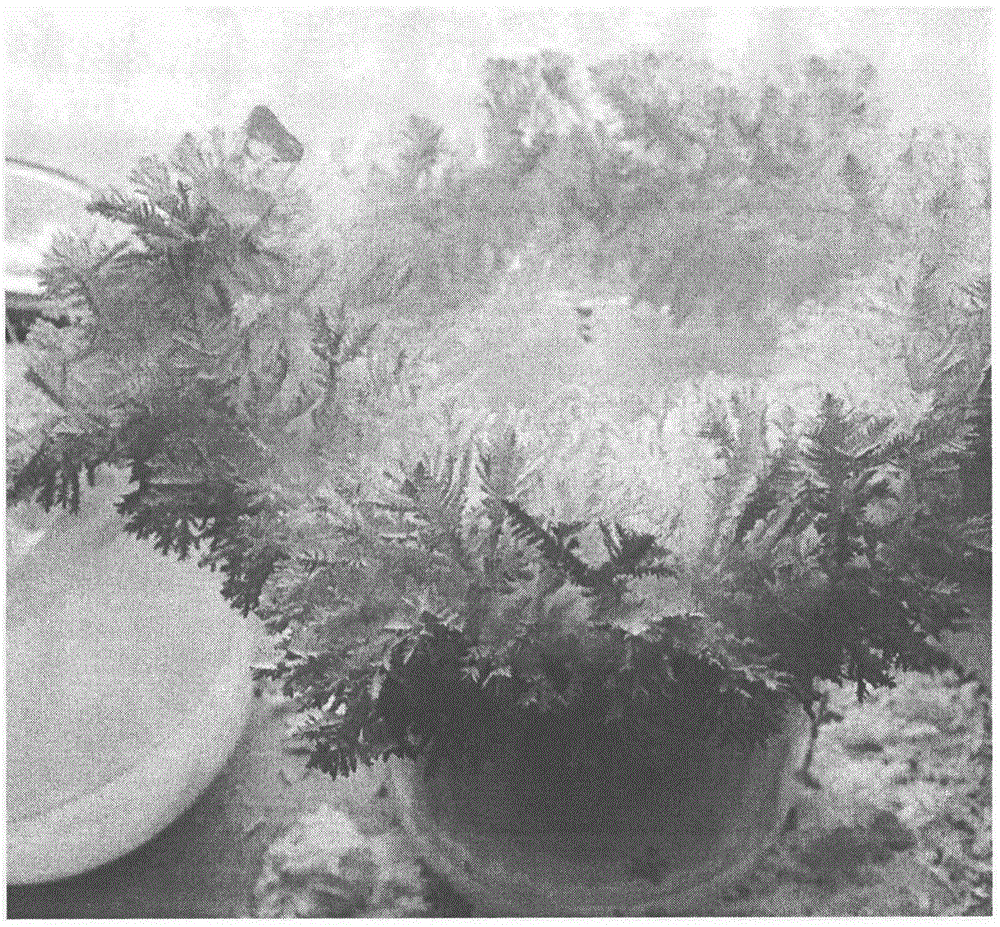

Image

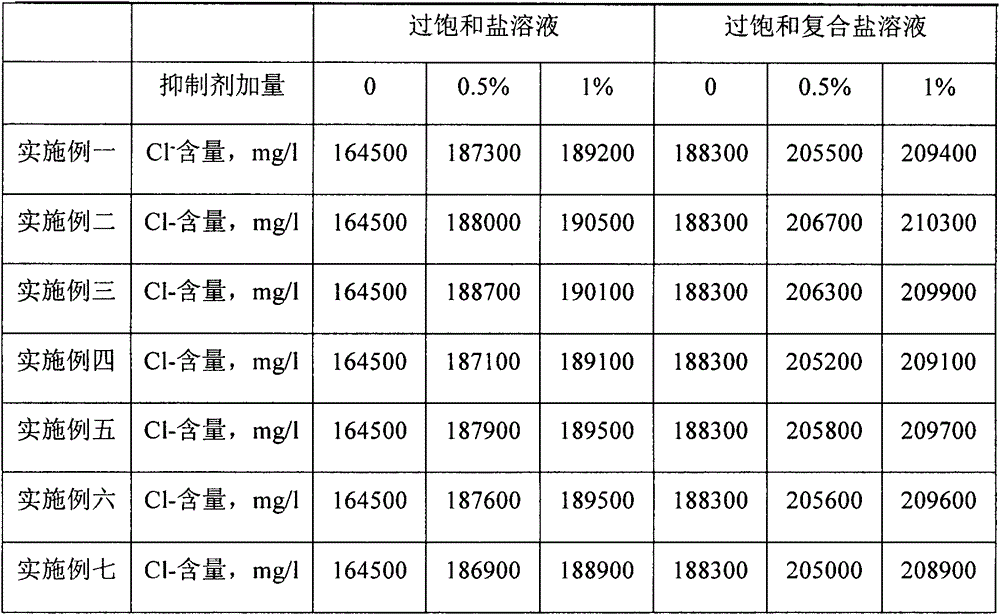

Examples

Embodiment 1

[0026] Take 100% of the total volume of each component: 60 parts of trisodium nitrilotriacetate, 35 parts of sodium sulfide, 2 parts of molybdate, and 3 parts of polyquaternary ammonium; add them to the reaction kettle in turn; react at 60 ° C ; The product obtained by the reaction synthesis is dried; the dried product is pulverized to obtain a light yellow powder, which is a salt recrystallization inhibitor for oil and gas wells.

Embodiment 2

[0028] Take 100% of the total volume of each component: 65 parts of sodium methylglycine diacetate, 27 parts of ammonium fluoride, 5 parts of tungstate, and 3 parts of sodium formate; add them to the reaction kettle in turn; react at 50 ° C; The product obtained by the reaction synthesis is dried; the dried product is pulverized to obtain a light yellow powder, which is a salt recrystallization inhibitor for oil and gas wells.

Embodiment 3

[0030] Take 100% of the total volume of each component: 70 parts of tetrasodium ethylenediaminetetraacetic acid, 23 parts of ammonium fluoride, 3 parts of polyphosphate, 4 parts of potassium formate; add them to the reaction kettle in sequence; carry out at 70 °C Reaction; drying the product obtained by the reaction synthesis; pulverizing the dried product to obtain a light yellow powder, which is a salt recrystallization inhibitor for oil and gas wells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com