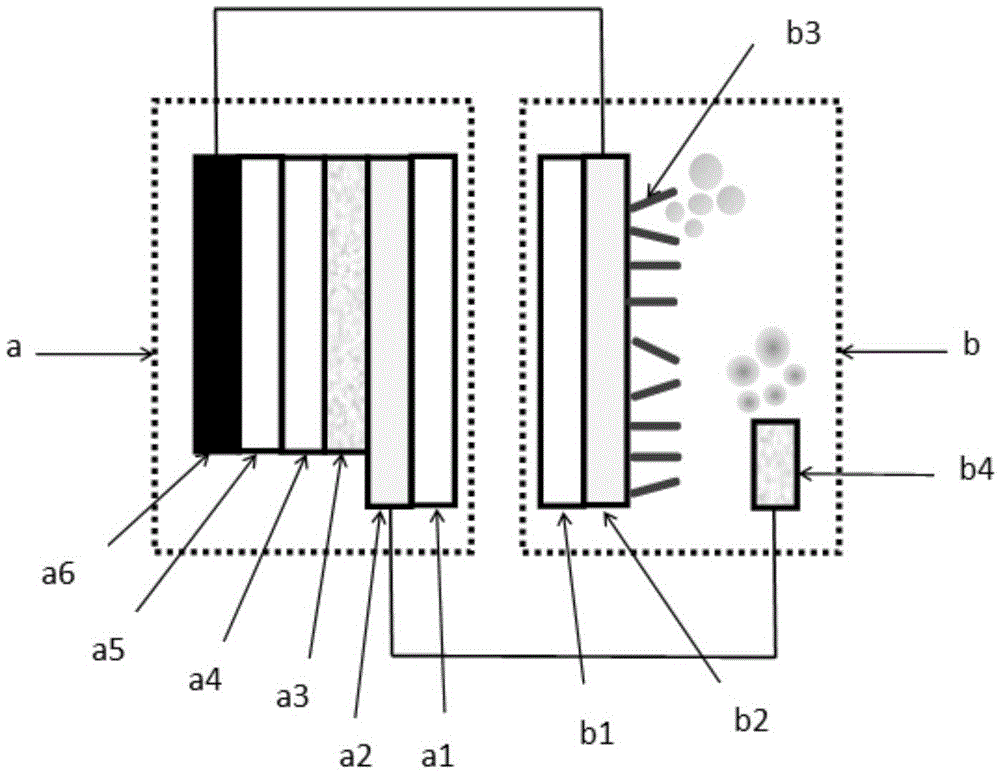

Water-electrolytic hydrogen making integrated device for perovskite solar cell and manufacturing method for integrated device

A perovskite solar energy and solar cell technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as low working voltage, complicated manufacturing, and lack of economical hydrogen production, so as to promote absorption , compact structure, good electron transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the preparation method of the perovskite solar cell water electrolysis hydrogen production integrated device comprises the following steps:

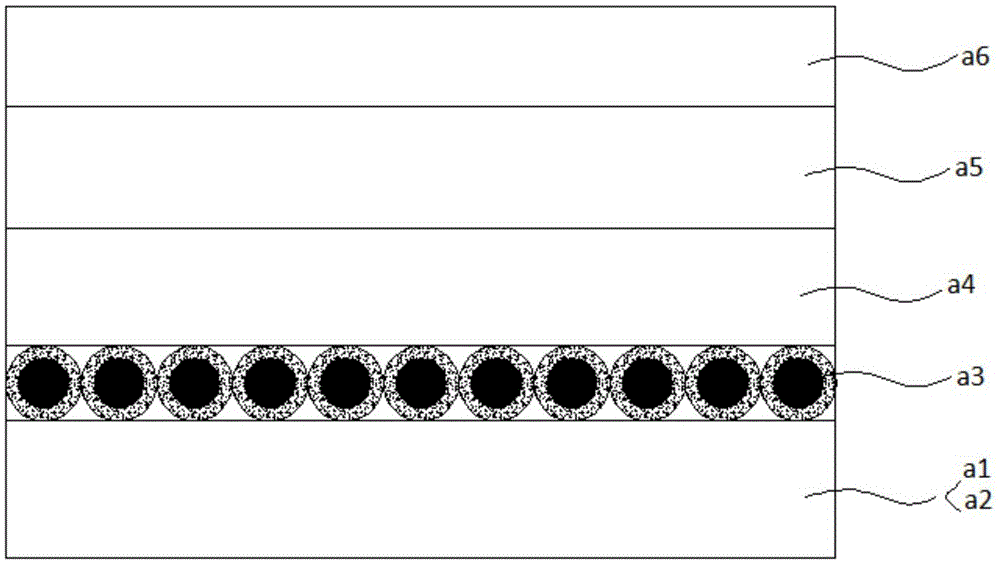

[0048] (1) Preparation of perovskite solar photovoltaic cell a:

[0049] a) Cleaning the FTO conductive glass substrate, first ultrasonically wash the FTO conductive glass substrate with a cleaning agent and deionized water to remove organics and grease, and then ultrasonically wash it with acetone, ethanol, and deionized water in turn; then the cleaned FTO conductive The glass substrate was immersed in an aqueous solution of polydiallyl dimethyl ammonium chloride with a volume concentration of 1% for 30 minutes; after the soaking, the FTO conductive glass substrate was taken out and repeatedly rinsed with deionized water to remove excess polydiallyl dimethyl ammonium chloride;

[0050] b) Under normal temperature, place the FTO conductive glass substrate obtained in step a) in AuTiO with a molar concentration...

Embodiment 2

[0061] In this embodiment, the preparation method of the perovskite solar cell water electrolysis hydrogen production integrated device comprises the following steps:

[0062] (1) Preparation of perovskite solar photovoltaic cell a:

[0063] a) Cleaning the ITO conductive glass substrate, first ultrasonically washing the ITO conductive glass substrate with cleaning agent and deionized water to remove organic matter and grease, and then ultrasonically washing the ITO conductive glass substrate with acetone, ethanol and deionized water in sequence; The glass substrate was immersed in an aqueous solution of polydiallyl dimethyl ammonium chloride with a volume concentration of 5% for 10 min; after immersion, the cathode transparent conductive substrate was taken out and repeatedly rinsed with deionized water to remove excess polydiallyl dimethyl ammonium chloride;

[0064] b) Under normal temperature, place the cathode transparent conductive substrate obtained in step a) in AgTiO...

Embodiment 3

[0075] In this embodiment, the preparation method of the perovskite solar cell water electrolysis hydrogen production integrated device comprises the following steps:

[0076] (1) Preparation of perovskite solar photovoltaic cell a:

[0077] a) Cleaning the ITO conductive glass substrate, first, the ITO conductive glass substrate is ultrasonically washed with a cleaning agent and deionized water to remove organics and grease, and then ultrasonically washed with acetone, ethanol, and deionized water in turn; then the cleaned ITO conductive glass substrate The glass substrate was immersed in an aqueous solution of polydiallyldimethylammonium chloride with a volume concentration of 2.5% for 20 minutes; after the soaking, the cathode transparent conductive substrate was taken out and repeatedly rinsed with deionized water to remove excess polydiallyl dimethyl ammonium chloride;

[0078] b) Under normal temperature, place the cathode transparent conductive substrate obtained in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com