Hemostasis composite material based on chitosan and marine mussel mucin and preparation method of hemostasis composite material

A technology of mussel mucin and composite materials, applied in medical science, absorbent pads, bandages, etc., to achieve the effect of easy operation, soft texture and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Weigh 0.2g of chitosan powder and dissolve it in 10ml of 0.1M dilute hydrochloric acid. After stirring for 0.5 hours, the obtained chitosan solution was sterilized under high temperature and high pressure at 121° C., cooled to room temperature, and used. Weigh 1.12g sodium β-glycerophosphate, add it into 2ml double distilled water, and dissolve to form a 56% sodium β-glycerophosphate solution. Filter through a 0.22 μm filter membrane and store in a 4°C refrigerator for later use. After the two solutions were ice-bathed for 15 minutes, the syringe sucked 9ml of the chitosan solution into a new beaker, stirred rapidly while adding 1ml of β-glycerophosphate sodium (β-GP) solution dropwise, and continued to stir. The homogeneously mixed product is placed in a constant temperature water bath at 37°C, and a milky white hydrogel can be formed within 5 minutes.

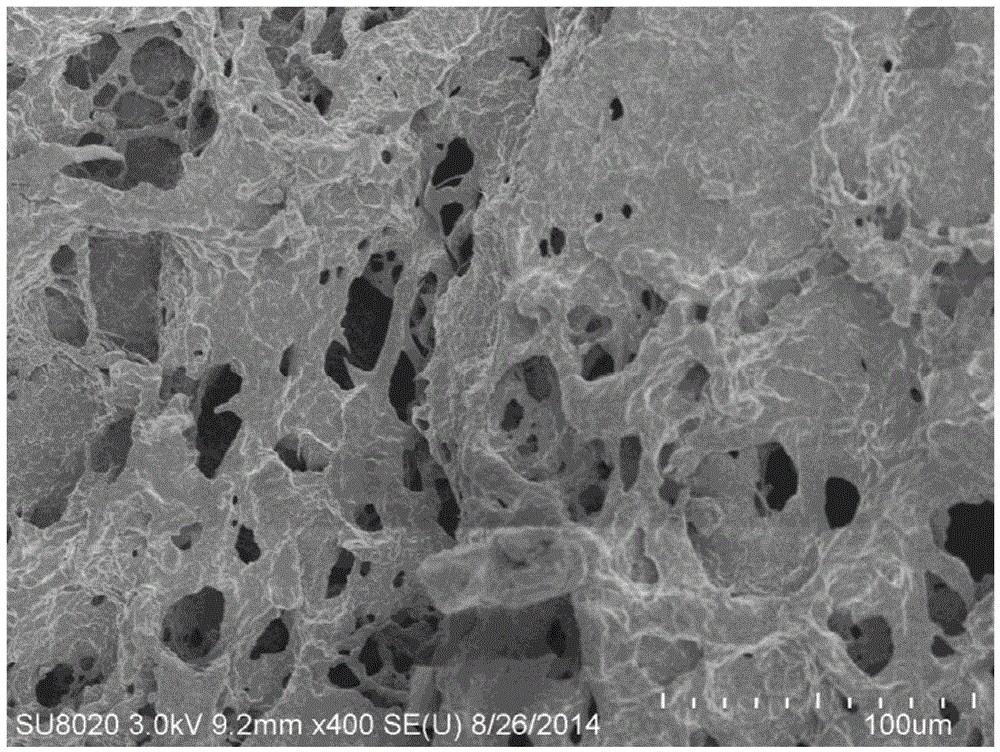

[0029] Cut chitosan hydrogel into 0.1cm 3 cubes were dehydrated in absolute ethanol for 5 min. The volume of ...

Embodiment 2

[0032] Weigh 0.3g of chitosan powder and dissolve it in 10ml of 0.1M dilute acetic acid. After stirring for 1 hour, add 1ml of mussel mucin solution of 10mg / ml to the chitosan solution, stir evenly, sterilize the obtained mixed solution at 121°C with high temperature and high pressure, cool to room temperature and use it. Weigh 1.2g of β-sodium glycerophosphate, add it into 2ml of double-distilled water, and dissolve to form a 60% sodium β-glycerophosphate solution. Filter through a 0.22 μm filter membrane and store in a 4°C refrigerator for later use. After the two solutions were ice-bathed for 15 minutes, the syringe sucked 7ml of the chitosan solution into a new beaker, stirred rapidly and added 1ml of the β-GP solution drop by drop, and continued to stir. The homogeneously mixed product is placed in a constant temperature water bath at 37°C, and a milky white hydrogel can be formed within 5 minutes.

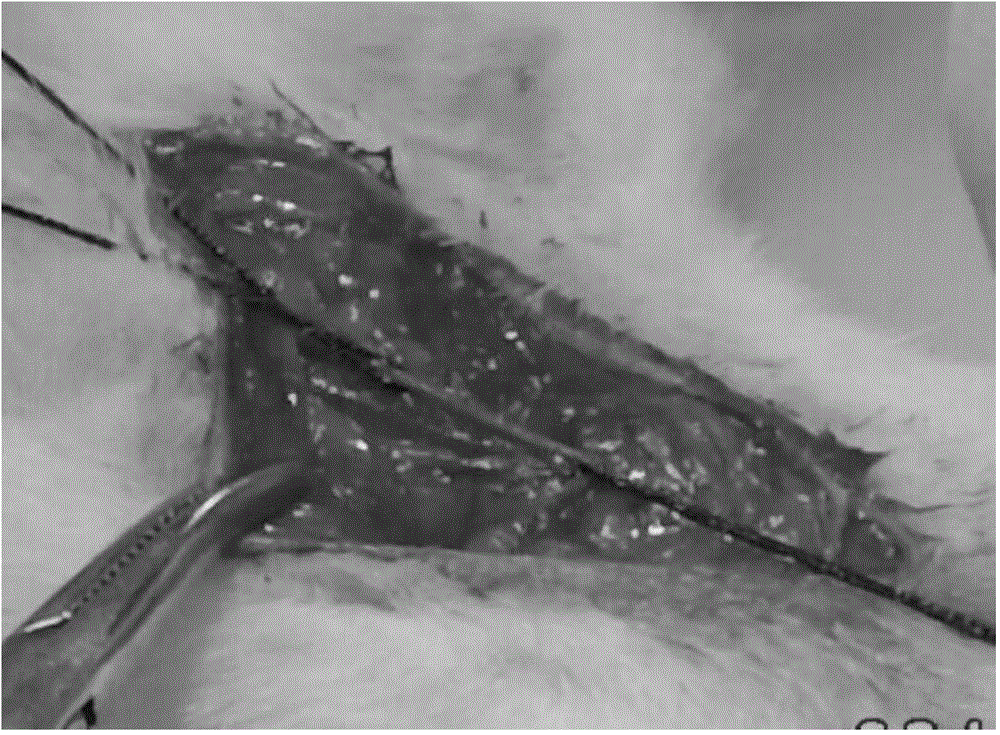

[0033] Anesthetized adult rats were fixed for the test, and a 0.5 mm i...

Embodiment 3

[0034] Weigh 10 g of polyethylene glycol 5000 grafted chitosan (grafting rate 45%, chitosan viscosity average molecular weight 200,000) powder, and dissolve it in 100 ml of 0.1 M dilute hydrochloric acid. After stirring for 1 hour, a gel was formed after cooling and standing.

[0035] Cut chitosan hydrogel into 1cm 3 cubes were dehydrated in absolute ethanol for 5 min. The volume of the gel after partial dehydration is 1 / 2 of the original volume. Put the dehydrated gel into the mussel mucin solution with a concentration of 1 mg / ml, and when the gel absorbs water, the mussel mucin also enters the hydrogel system. The morphology and properties of the chitosan hydrogel system after reabsorbing water did not change compared with those before dehydration. The obtained finished product is the target product chitosan hydrogel and marine mussel mucin hemostatic composite material.

[0036] An anesthetized adult rat was fixed for the test, and a 0.5 mm incision was made on the caro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com