Production technology of steel-copper bimetal composite material for bearing manufacture

A composite material and production process technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of low bulk density of copper powder, decrease of porosity of copper powder, high bulk density, etc., and achieve copper powder layer The effect of reducing the chance of shedding, improving physical properties, and stabilizing bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

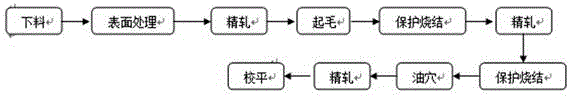

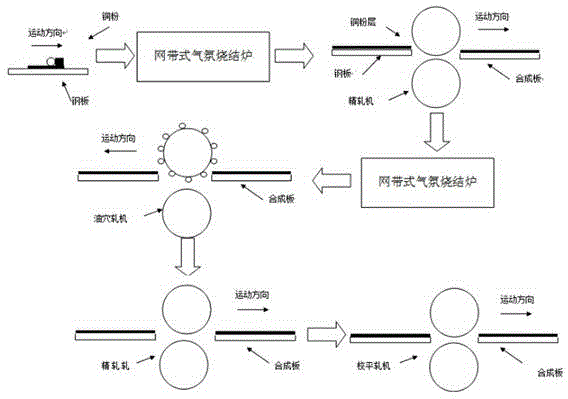

[0019] Example 1, such as figure 1 , 2 As shown, a production process for making bearing steel-copper bimetallic composite materials includes blanking, surface treatment, finish rolling before sintering, part of the cold plate does not fluff in the original production process, protection sintering, finish rolling, secondary protection sintering, The oil hole, finishing rolling and leveling steps are completed, and the specific implementation steps are as follows;

[0020] 1) Cutting: Cut the steel plate into specified length and width according to product requirements;

[0021] 2) Surface treatment: Different surface treatment methods have been formulated for the cold plate and the middle plate. The cold plate is degreasing, and the middle plate is pickled and passivated to remove the rust on the surface so that the copper powder and the steel plate can be firm. Sintered together, improving the bonding strength of the composite material;

[0022] 3) After finishing rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com