High-strength dialdehyde microfibrillar cellulose/chitosan composite membrane and preparation method and application thereof

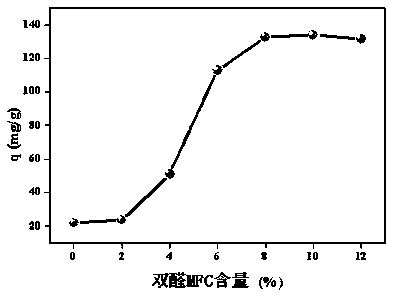

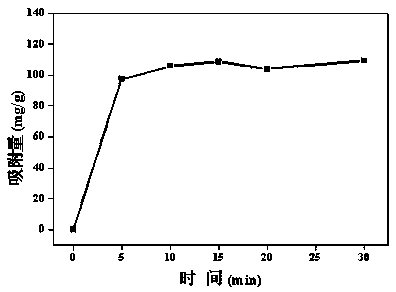

A technology of microcrystalline cellulose and chitosan, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problem of poor mechanical properties and low stability of pure chitosan membranes problems, achieve high strength, improved mechanical strength, and increased adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of pure chitosan film: (1) Add 1 g of chitosan to 100 mL of 1 wt% acetic acid solution, stir in a constant temperature water bath at 55 °C for 2 h to obtain chitosan solution; (2) cast chitosan The sugar solution was spread on a polytetrafluoroethylene plate and dried at 40°C to form a film.

Embodiment 2

[0035] A preparation method of high-strength dialdehyde microfibrillated cellulose / chitosan composite film, comprising the steps of:

[0036] (1) Soak microcrystalline cellulose in 10% NaOH aqueous solution, stir at 60°C for 2 hours, and filter. The treated microcrystalline cellulose was washed with deionized water to neutrality; mixed with deionized water and transferred to a high-pressure homogenizer, homogenized 20 times under a pressure of 1000 bar to obtain an MFC suspension with a MFC content of 0.5wt%;

[0037] (2) Add 1.6g of sodium periodate to 400g of 0.5wt% MFC suspension, stir in a constant temperature water bath at 25°C in the dark for 48 hours, then dialyze with deionized water for 2 days, let it stand, and remove part of the supernatant Afterwards, obtain the dialdehyde MFC suspension of solid content 1.93wt%;

[0038] (3) 4g chitosan is dissolved in the acetic acid solution of 400mL1wt%, obtains chitosan acetic acid solution;

[0039] (4) 4.14g of 1.93wt% dia...

Embodiment 3

[0041] A preparation method of high-strength dialdehyde microfibrillated cellulose / chitosan composite film, comprising the steps of:

[0042] (1) Soak microcrystalline cellulose in 10% NaOH aqueous solution, stir at 60°C for 2 hours, and filter. The processed microcrystalline cellulose was washed to neutrality with deionized water; mixed with deionized water and then transferred to a high-pressure homogenizer, homogenized 20 times under a pressure of 1000 bar to obtain an MFC suspension with an MFC content of 1.5wt%;

[0043] (2) Add 4.8g of sodium periodate to 400g of 1.5wt% MFC suspension, stir in a constant temperature water bath at 25°C in the dark for 48h, then dialyze with deionized water for 2 days, let it stand, and remove part of the supernatant Afterwards, obtain the dialdehyde MFC suspension of solid content 1.93wt%;

[0044] (3) 4g chitosan is dissolved in the acetic acid solution of 400mL1wt%, obtains chitosan acetic acid solution;

[0045](4) 12.4g of 1.93wt% d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com