A large-scale thin-walled cordierite honeycomb ceramic carrier mud and its preparation method

A cordierite honeycomb, ceramic carrier technology, applied in ceramic products, other household appliances, household appliances and other directions, can solve the problems of easy damage to equipment molds, poor mud fluidity, large extrusion resistance, etc., to reduce firing cracking, Low molding pressure and lower thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

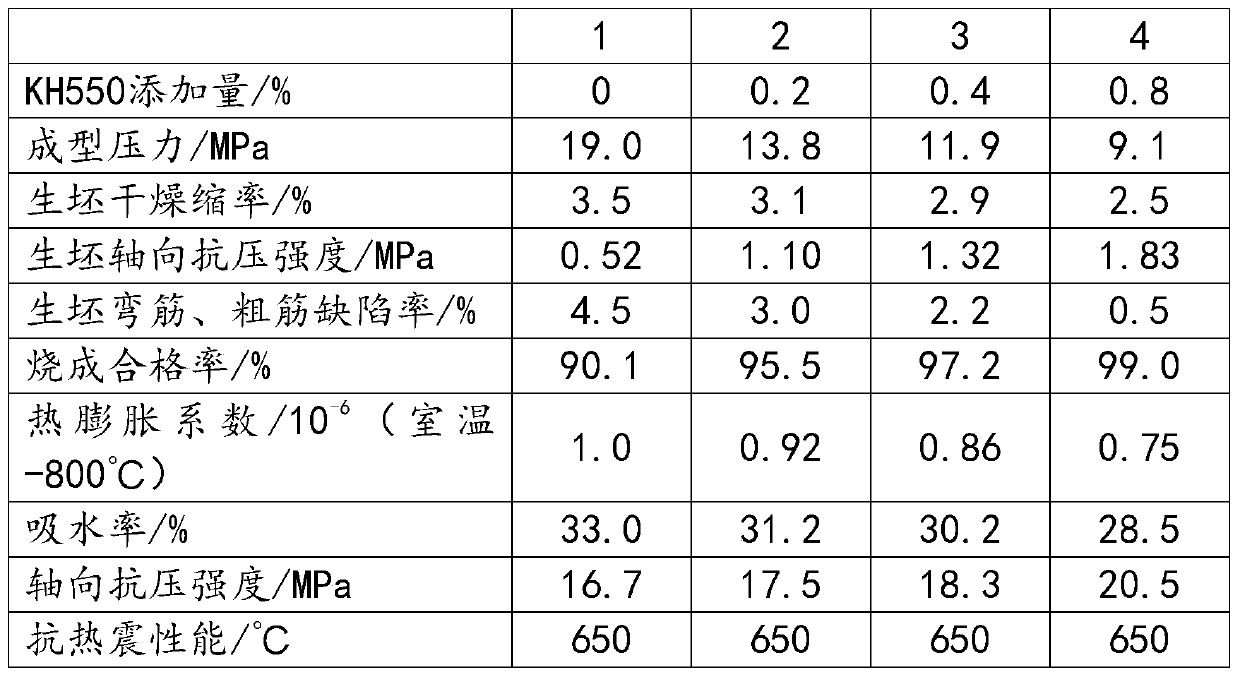

Embodiment 1

[0020] (1) Inorganic powder composition: D50=15 μm flake talc 40.0%, D50=6 μm raw kaolin 29.8%, D50=20 μm flake alumina 21.2%, D50=4.0 μm fused quartz 9.0%. After the inorganic powder is dry-mixed without gravity, add 4% methylcellulose, 0.5% silicone polyether copolymer, 1% soybean oil and 35% water for kneading and vacuum refining. The molding machine operates at 19.0 The pressure of MPa extrudes the mud material into a thin-walled honeycomb ceramic catalyst carrier green body with 300 holes / in2 of Φ13×6in. and a wall thickness of 5mil. After drying, the shrinkage rate of the green body is 3.5%, and the axial compressive strength is tested. : 0.52MPa, bending and thick rib defect rate: 4.5%.

[0021] (2) After firing at 1415° C. and holding the heat for 8 hours, the cordierite catalyst carrier is obtained, and the firing pass rate is 90.1%. Product performance: thermal expansion coefficient 1.0×10-6 / °C (room temperature -800°C), water absorption rate 33%, axial compressive ...

Embodiment 2

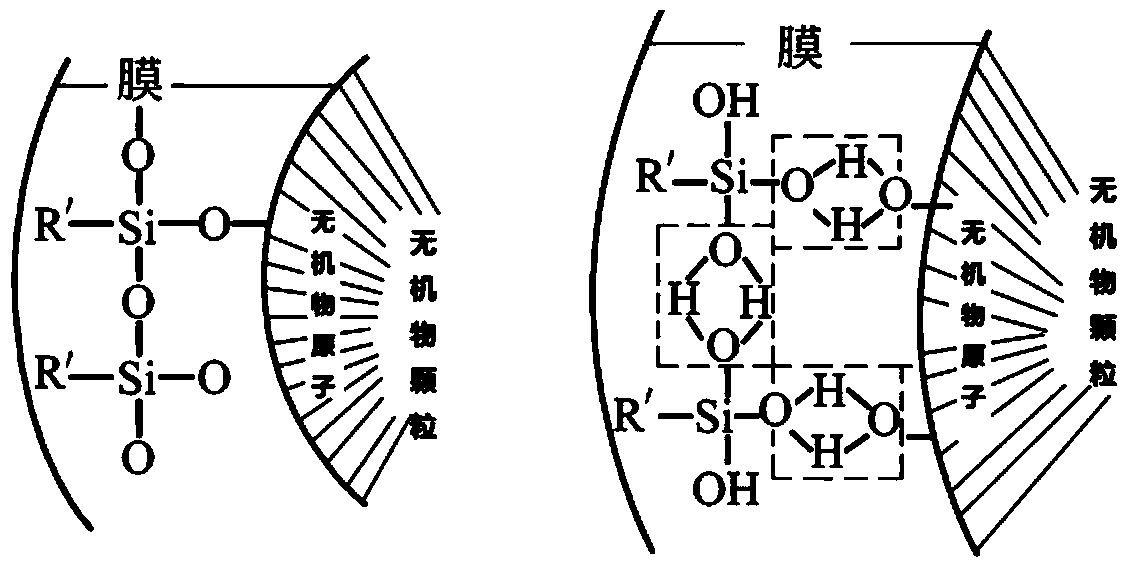

[0023] (1) Inorganic powder composition: D50=15 μm flake talc 40.0%, D50=6 μm raw kaolin 29.8%, D50=20 μm flake alumina 21.2%, D50=4.0 μm fused quartz 9.0%. Add 0.2% KH550 silane coupling agent and dry-mix synchronously with the powder to modify the powder.

[0024] (2) Add 5% methyl cellulose, 0.5% silicone polyether copolymer, 1% soybean oil and 25% water, knead and vacuum mud, and the molding machine squeezes the mud with a pressure of 13.8MPa The thin-walled honeycomb ceramic catalyst carrier green body with Φ13×6in. 300 holes / in2 and wall thickness 5mil was tested after drying. The drying shrinkage: 3.1%, the axial compressive strength: 1.10MPa, and the defects of bending ribs and thick ribs Rate: 3.0%.

[0025] (3) After firing at 1415°C and keeping it warm for 8 hours, the cordierite catalyst carrier was obtained with a firing pass rate of 95.5%. Product performance: thermal expansion coefficient 0.92×10-6 / °C (room temperature-800°C), water absorption rate 31.2%, The ...

Embodiment 3

[0027] (1) Inorganic powder composition: D50=15 μm flake talc 40.0%, D50=6 μm raw kaolin 29.8%, D50=20 μm flake alumina 21.2%, D50=4.0 μm fused quartz 9.0%. Add 0.4% of KH550 silane coupling agent and dry mix synchronously with the powder to modify the powder.

[0028] (2) Add 5% methyl cellulose, 0.5% silicone polyether copolymer, 1% soybean oil and 25% water, knead and vacuum mud, the molding machine squeezes the mud with a pressure of 11.9MPa The thin-walled honeycomb ceramic catalyst carrier green body with Φ13×6in. 300 holes / in2 and wall thickness 5mil was tested after drying. The drying shrinkage: 2.9%, the axial compressive strength: 1.32MPa, and the defects of bending ribs and thick ribs Rate: 2.2%.

[0029] (3) After firing at 1415°C and keeping it warm for 8 hours, the cordierite catalyst carrier was obtained with a firing pass rate of 97.2%. Product performance: thermal expansion coefficient 0.86×10-6 / °C (room temperature-800°C), water absorption rate 30.2%, The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com