Degradable silica-based hybrid polymer biomedical elastomer and preparation method thereof

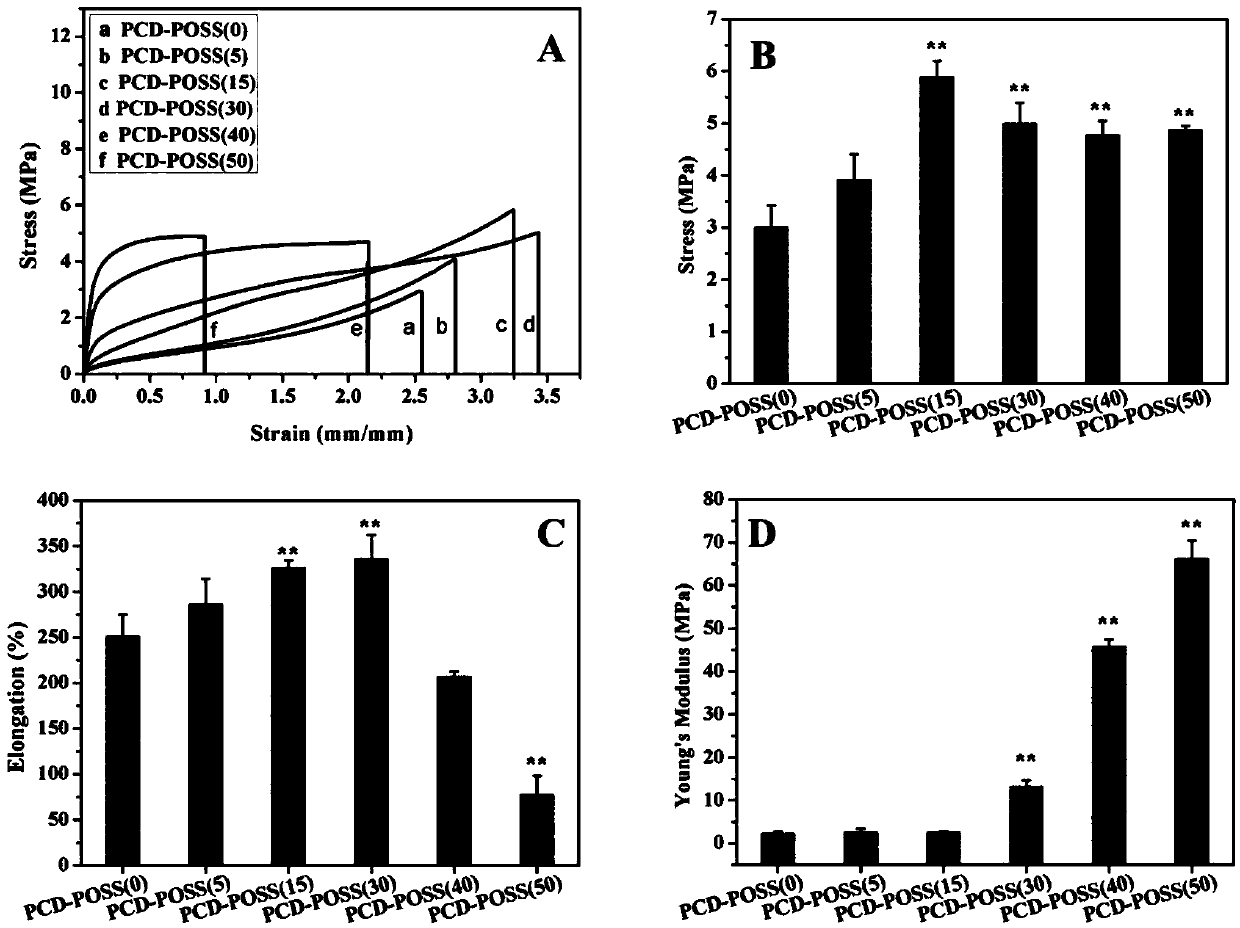

A biomedical and elastic body technology, which is applied in the field of degradable silicon-based hybrid polymer biomedical elastomer and its preparation, can solve problems such as hindering practical application, unfavorable tissue repair, and lack of biological activity, and achieve monomer biophase Good capacitive properties, enhanced mechanical properties and elastic behavior, high biological stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

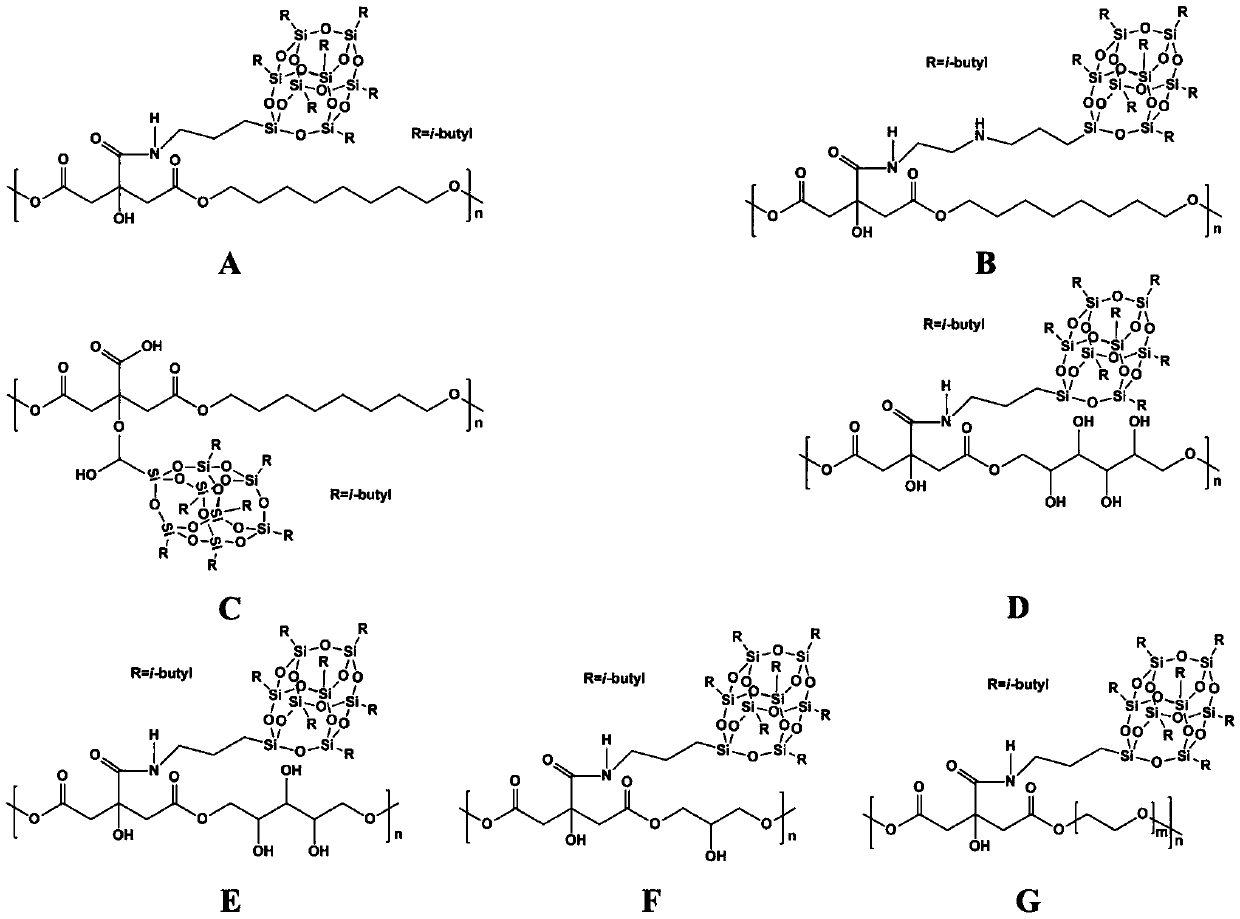

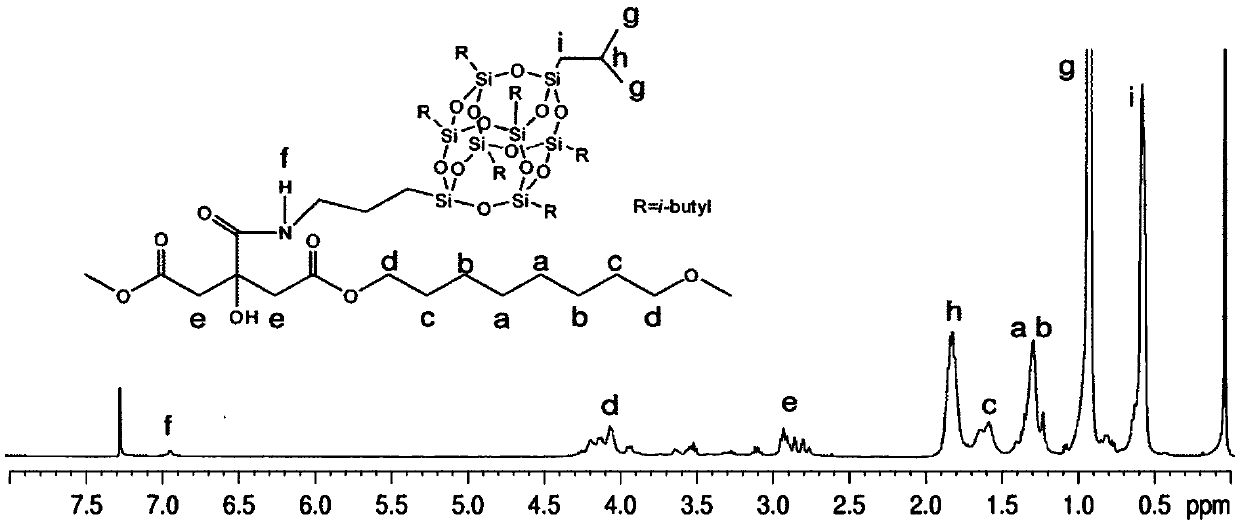

Method used

Image

Examples

Embodiment 1

[0037] 1) Preparation of PCD prepolymer: The molar ratio of citric acid: 1,8-octanediol is 1:1.1, and the total mass is 5.0 g. Add it to a 50 mL round-bottomed flask, stir it in a nitrogen environment and put it at 160 °C Melt in an oil bath; after the reaction monomers citric acid and 1,8-octanediol are all melted, the temperature is immediately lowered to 140° C., and the reaction is carried out in a nitrogen environment for 1 hour. The reaction product was washed three times with deionized water, centrifuged, and freeze-dried for later use;

[0038] 2) Preparation of PCD-g-POSS prepolymer: the molar ratio of citric acid: 1,8-octanediol: aminopropyl isobutyl POSS is 1: 1.1: 0.8, and the total mass is 5.0 g. In a 50mL round-bottomed flask, stir and dissolve in a 160°C oil bath under nitrogen atmosphere; after citric acid and 1,8-octanediol are all melted, the temperature immediately drops to 140°C, and the reaction is performed in a nitrogen atmosphere for 1 hour. The reacti...

Embodiment 2

[0042] 1) Preparation of PCD prepolymer: the molar ratio of citric acid: glycerin is 1:0.8, and the total mass is 5.0 g, added to a 50 mL round-bottomed flask, stirred in a nitrogen environment and put into a 160 ° C oil bath to melt; After the reaction monomers citric acid and glycerol were all melted, the temperature was immediately lowered to 142° C., and the reaction was carried out in an argon atmosphere for 1 hour. The reaction product was washed three times with deionized water, centrifuged, and freeze-dried for later use;

[0043] 2) Preparation of PCD-g-POSS prepolymer: according to the molar ratio of citric acid: glycerol: aminopropyl isobutyl POSS of 1:0.8:0.4, the total mass is 5.0g, and added to a 50mL round bottom flask, Stir in a nitrogen environment and put it into a 160°C oil bath to melt; after the citric acid and glycerin are all melted, the temperature immediately drops to 142°C, and the reaction is performed in a nitrogen environment for 1 hour. The react...

Embodiment 3

[0047] 1) Preparation of PCD prepolymer: the molar ratio of citric acid: xylitol is 1:0.9, and the total mass is 5.0 g. Add it into a 50 mL round-bottomed flask, stir it in a 160°C oil bath under nitrogen atmosphere and melt it in an oil bath. ; After the reaction monomers citric acid and xylitol are all melted, the temperature is immediately reduced to 145 ° C, and the reaction is carried out in a helium atmosphere for 1 hour. The reaction product was washed three times with deionized water, centrifuged, and freeze-dried for later use;

[0048] 2) Preparation of PCD-g-POSS prepolymer: the molar ratio of citric acid: xylitol: aminopropyl isobutyl POSS is 1:0.9:0.5, the total mass is 5.0g, and it is added to a 50mL round bottom flask , stir in a nitrogen atmosphere and put it into a 160°C oil bath to melt; after all the citric acid and xylitol are melted, the temperature immediately drops to 145°C, and the reaction is performed in a nitrogen atmosphere for 1 hour. The reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com