Polishing liquid for metallographic analysis and preparation method and application method thereof

A technology of metallographic analysis and polishing liquid, which is applied in the field of polishing liquid, can solve the problems of sticky paste, expensive, difficult to disperse, etc., and achieve the effect of fine solid particles, low price and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The content of the present invention is further described below by way of examples.

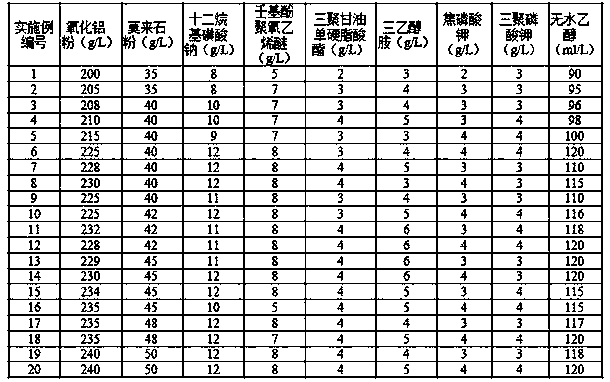

[0056] The composition and content of the stainless steel polishing paste in the examples are shown in the table below, and the remaining dispersion medium is deionized water.

[0057]

[0058] The average particle size of alumina powder and mullite powder in the raw materials is 30 μm, and the polishing paste preparation method is as follows:

[0059] (1) Dissolve sodium dodecyl sulfonate, nonylphenol polyoxyethylene ether, triglycerol monostearate, and triethanolamine in absolute ethanol;

[0060] (2) Dissolving potassium pyrophosphate and potassium tripolyphosphate in deionized water;

[0061] (3) Mix the ethanol solution and the aqueous solution and stir evenly;

[0062] (4) Put alumina powder and mullite powder into the above mixed solution;

[0063] (5) Put the above mixture into a high-speed disperser and disperse at a speed of 4500r / min for 4 hours;

[0064] (6) The disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com