Suspension-type vinasse fermented liquid fertilizer and preparation method thereof

A fermented liquid and suspension technology, applied in nitrogen fertilizer, potassium fertilizer, phosphate fertilizer, etc., can solve the problems of inconvenient transportation, unfavorable plant growth, stimulation, etc., and achieve the effect of good fluidity, convenient use, and reduced particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

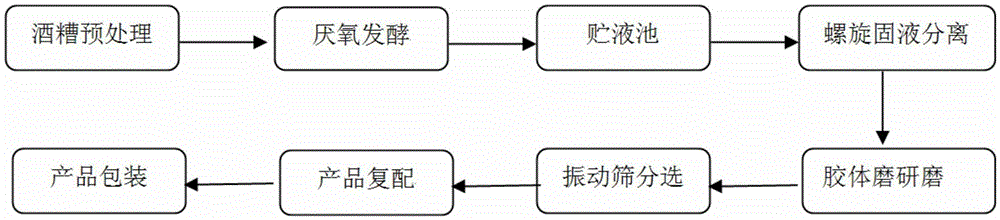

Method used

Image

Examples

Embodiment 1

[0026] The suspension-type distiller's grain fermented liquid fertilizer described in this embodiment includes the following ratio of raw materials: 89.2 parts of mother liquor after treatment of distiller's grains fermented liquid, 1 part of suspension stabilizer, 3 parts of urea, 1.2 parts of diammonium phosphate, and 5.6 parts of potassium sulfate.

Embodiment 2

[0028] The suspension-type distiller's grain fermented liquid fertilizer described in this embodiment includes the following ratio of raw materials: 89.5 parts of mother liquor after treatment of distiller's grains fermented liquid, 1 part of suspension stabilizer, 4.5 parts of urea, 2.5 parts of diammonium phosphate, and 2.5 parts of potassium sulfate.

Embodiment 3

[0030] The suspension-type distiller's grain fermented liquid fertilizer described in this embodiment includes the following ratio of raw materials: 90 parts of mother liquor after treatment of distiller's grains fermented liquid, 1 part of suspension stabilizer, 3 parts of urea, 3 parts of diammonium phosphate, and 3 parts of potassium sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com