Magnetooptical material, manufacturing method therefor, and magnetooptical device

A technology of magneto-optical materials and manufacturing methods, which is applied in the growth of polycrystalline materials, chemical instruments and methods, optics, etc., and can solve problems such as difficulty in utilizing optical isolators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

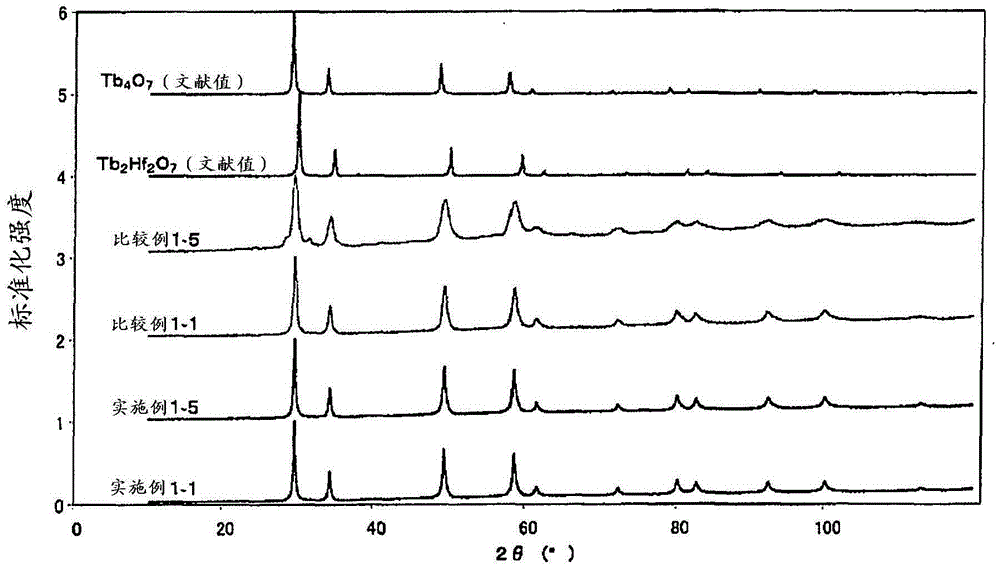

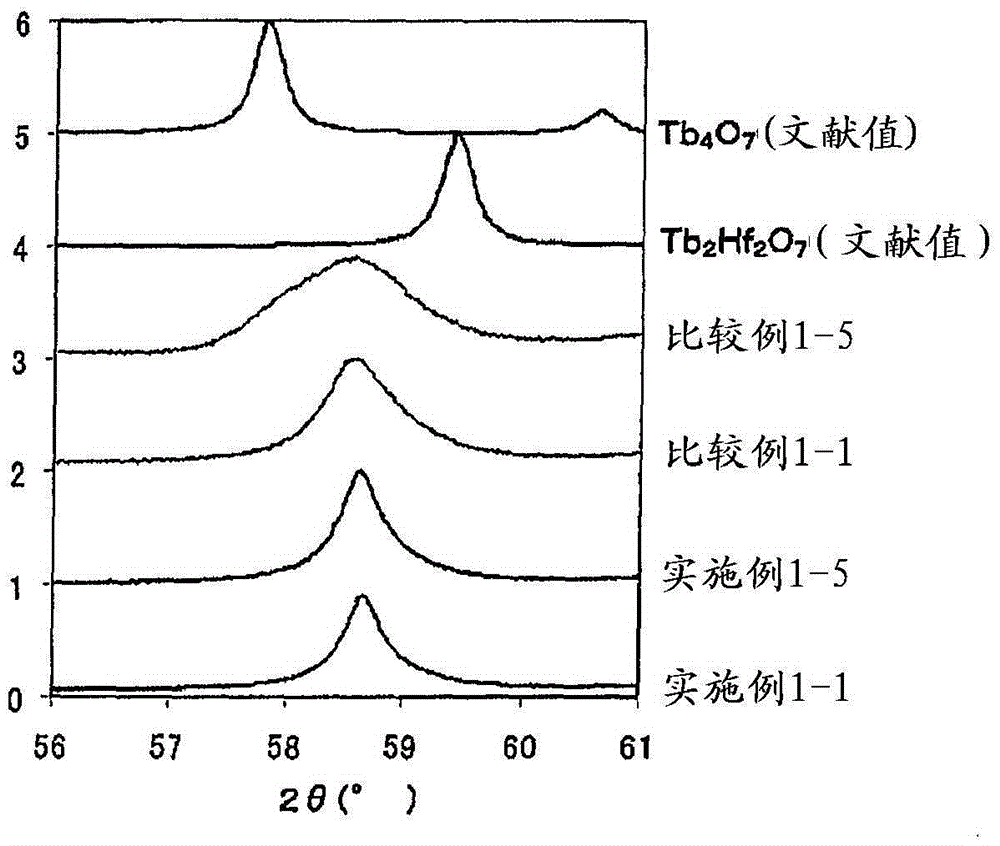

[0110] [Example 1, Comparative Example 1]

[0111] As an example in which a single element is filled at the B site (R in the above formula (1)) in the above formula (1), an example in which hafnium, tin, titanium, and zirconium are selected will be described.

[0112] Terbium oxide powder from Shin-Etsu Chemical Co., Ltd., hafnium oxide powder from American Elements Co., Ltd., tin oxide powder and titanium oxide powder from High Purity Chemical Research Institute Co., Ltd., and Nissan Chemical Industry Co., Ltd. Zirconia powder. All have a purity of 99.9% by mass or higher.

[0113] Using the above raw materials, Tb 2 f 2 o 7 , Tb 2 sn 2 o 7 , Tb 2 Ti 2 o 7 , Tb 2 Zr 2 o 7 4 kinds of pyrochlore-type oxide raw materials. That is, prepare a mixed powder in which terbium oxide and hafnium oxide are weighed so that terbium and hafnium become an equimolar ratio, a mixed powder in which terbium oxide and tin oxide are weighed so that terbium and tin become an equimolar...

Embodiment 2

[0175] [Example 2, Comparative Example 2]

[0176] An example in which at least one element selected from silicon, germanium, titanium, tantalum, and tin is filled at the B site in the above formula (1) so as to have a composition other than the composition of Example 1 will be described.

[0177] Terbium oxide powder manufactured by Shin-Etsu Chemical Co., Ltd., silicon dioxide powder, germanium dioxide powder, titanium oxide powder, tin oxide powder manufactured by Shin-Etsu Chemical Co., Ltd. of tantalum pentoxide. All have a purity of 99.9% by mass or more.

[0178] Using the above raw materials, various composite oxide raw materials were produced. That is, prepare to weigh terbium oxide, silicon dioxide, and zirconia so that the molar ratio of terbium, silicon, and zirconium becomes a mixed powder of 2:1:1, and weigh terbium oxide, germanium dioxide, and zirconia so that terbium, germanium, and The molar ratio of zirconium and zirconium is 2:1:1 mixed powder, weigh ter...

Embodiment 3

[0190] Another example in which hafnium and zirconium are selected as the B site in the above formula (1) will be described.

[0191] Terbium oxide powder manufactured by Shin-Etsu Chemical Co., Ltd., hafnium oxide powder manufactured by American Elements Corporation, and zirconia powder manufactured by Nissan Chemical Industry Co., Ltd. were obtained. All have a purity of 99.9% by mass or more.

[0192] Using the above raw materials, Tb 2 f 2 o 7 , Tb 2 Zr 2 o 7 2 kinds of pyrochlore-type oxide raw materials. That is, two kinds of mixed powders were prepared, namely, a mixed powder in which terbium oxide and hafnium oxide were weighed so that terbium and hafnium had an equimolar ratio, and a mixed powder in which terbium oxide and zirconia were weighed so that terbium and zirconium had an equimolar ratio. Next, dispersion / mixing treatment was carried out in ethanol using a zirconia ball mill apparatus while being careful not to mix with each other. Processing time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com