Ornamental water grass cultivation medium and processing method thereof

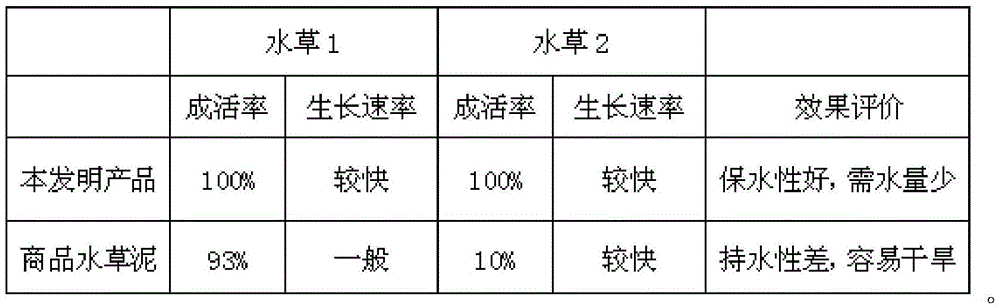

The technology of a cultivation medium and a processing method is applied in the directions of cultivation, soilless cultivation, planting substrate, etc., and can solve the problems that aquatic plants cannot be grown directly in aquarium, the cultivation substrate is difficult to choose, and the water quality requirements are high, and the production cost is low and convenient. The effect of cultivation management and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The cultivation medium for ornamental aquatic plants provided by the present invention is composed of the following components in parts by weight:

[0021] Peat, 20 parts; Granular controlled-release fertilizer, 1.5 parts; Starch, 0.5 parts; Arabic gum, 1 part; Carbendazim, 0.1 part;

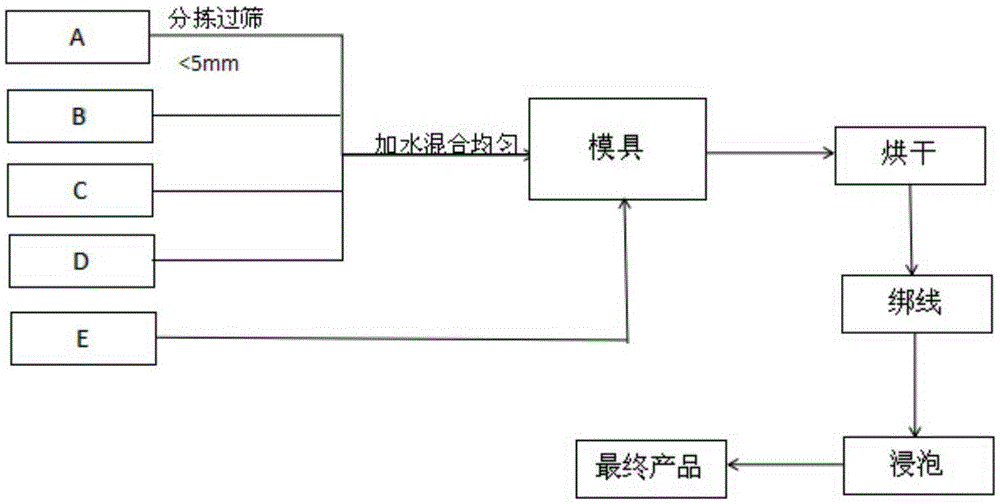

[0022] The above-mentioned ornamental aquatic plants production cultivation medium processing method, the specific steps are as follows:

[0023] 1. Calculated in parts by weight, take 20 parts of raw material A peat, sort and sieve, mix with 0.5 part of raw material B starch, 1 part of raw material C gum arabic, 0.1 part of raw material C carbendazim, and add water to reconcile;

[0024] 2. Pour the above mixture into a 7*7*2cm mold, add E1.5 parts of controlled-release fertilizer, and press it into cubes;

[0025] 3. Put the pressed media block into an oven at 105°C and dry for 12 hours;

[0026] 4. After drying, the medium block is tied up in a grid shape with thin wires, and soaked ...

Embodiment 2

[0028] The cultivation medium for ornamental aquatic plants provided by the present invention is composed of the following components in parts by weight:

[0029] Peat, 35 parts; Granular controlled-release fertilizer, 3 parts; Starch, 0.8 part; Arabic gum, 5 parts; Carbendazim, 0.2 part;

[0030] The above-mentioned ornamental aquatic plants production cultivation medium processing method, the specific steps are as follows:

[0031] 1. Calculated in parts by weight, take 35 parts of raw material A peat, sort and sieve, mix with 0.8 part of raw material B starch, 5 parts of raw material C gum arabic, 0.2 part of raw material C carbendazim, and add water to reconcile;

[0032] 2. Pour the above mixture into a 7*7*2cm mold, add E3 controlled-release fertilizer, and press it into cubes;

[0033] 3. Put the pressed media block into a 100°C oven and dry it for 12 hours;

[0034] 4. After drying, the medium block is tied up in a grid shape with thin wires, and soaked for 4 days to...

Embodiment 3

[0036] Product property evaluation of the present invention, evaluation content comprises:

[0037] 1. The stability of the medium block in water

[0038] 2. The effect of medium block on water quality

[0039] Specific steps are as follows:

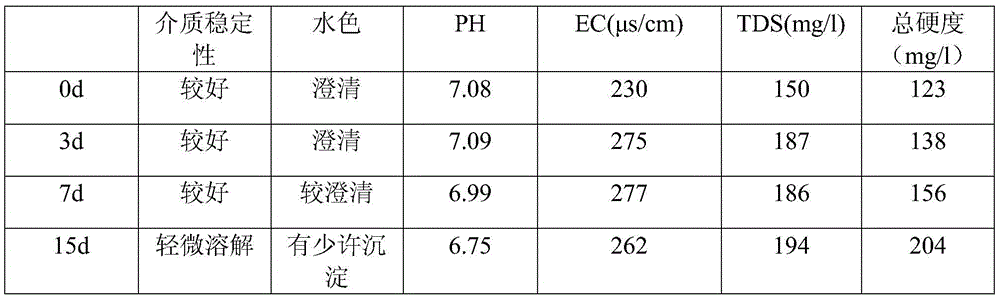

[0040] 1. Soak a certain number of media blocks with the same size and weight in the same container with 3L distilled water and the same specifications;

[0041] 2. According to the interval of days, observe the stability of the medium block respectively at 0d, 3d, 7d, and 15d, and measure the water quality indicators (water color, PH, DO, TDS, total hardness).

[0042] The test results are as follows (Table 1):

[0043] 1. The medium block has good stability during soaking in water, and no obvious decomposition occurs.

[0044] 2. During the test period, the water quality indicators were all within the normal range. Except for the slight acidification effect of the medium block on the water body, other indicators had little effect. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com