Modified filling for waste gas bio-trickling filter and preparation method of modified filling

A bio-trickling filter tower and exhaust gas technology, applied in the direction of separation methods, air quality improvement, chemical instruments and methods, etc., can solve the problems of slow biofilm formation process, increased reactor start-up time, difficulty in stabilizing treatment efficiency, etc., and achieve raw material Low cost, improved biological treatment efficiency, and the effect of improving waste gas treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

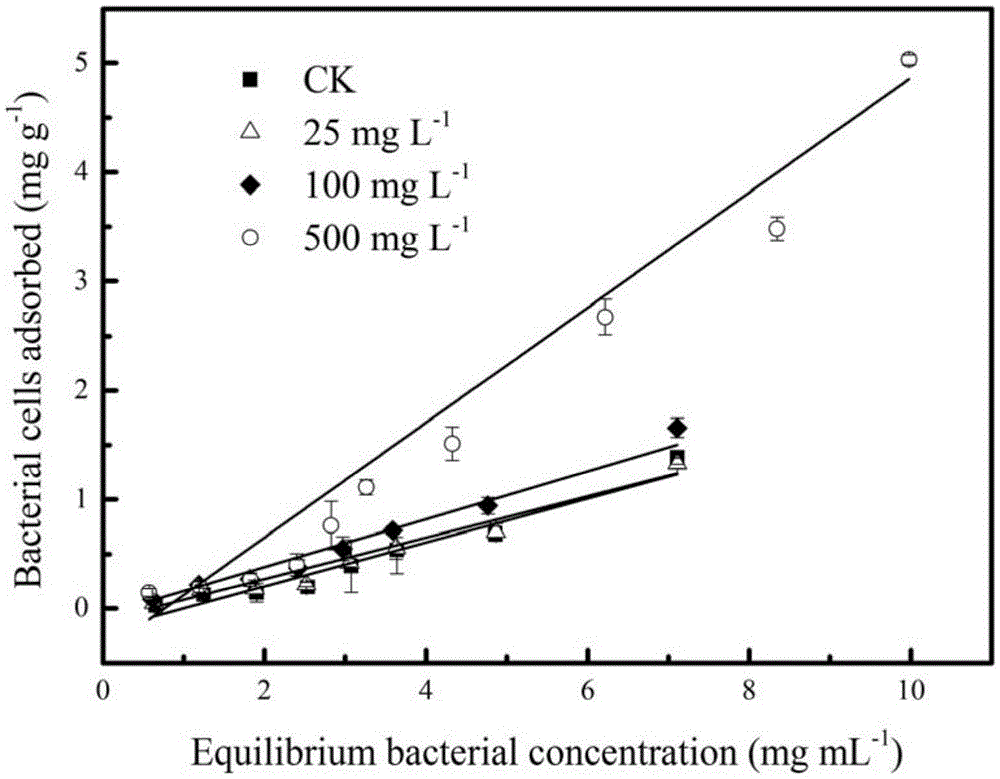

[0026] The ceramsite is screened to obtain raw materials with a particle size of 5-100mm. After washing with water, put the washed ceramsite in 1.0molL -1 After soaking in aqueous hydrochloric acid for 24 hours, rinse thoroughly, and then use a concentration of 1.0molL -1 Soak in NaOH aqueous solution for 24 hours, take out the ceramsite and wash it with water until neutral. Then the ceramsite was dried at 110°C and placed in 25mgL -1 , 100, 500mgL -1 Immerse in polyethyleneimine (molecular weight: 1800) aqueous solution for 10 minutes, drain and dry at 90°C to become the modified filler for waste gas biological trickling filter tower.

[0027] Adsorption of degrading bacteria on the filler surface before and after modification: Weigh a certain amount of filler (modified filler for waste gas biological trickling filter tower or unmodified ceramsite with a particle size of 5-100mm) in a series of glass conical flasks, add Appropriate amount of mineral salt medium (medium for...

Embodiment 2

[0030] The ceramsite is screened to obtain raw materials with a particle size of 5-100mm. After washing with water, put the washed ceramsite in 3.0molL -1 After soaking in aqueous hydrochloric acid solution for 4 hours, rinse thoroughly, and then use a concentration of 2.0molL -1 Soak in NaOH aqueous solution for 4 hours, take out the ceramsite and wash it with water until neutral. Then the ceramsite was dried at 90°C and placed in 200mgL -1 Immerse in polyethyleneimine (molecular weight: 70,000) aqueous solution for 10 minutes, drain and dry at 90°C to become a modified filler for waste gas biological trickling filter tower.

[0031] According to the method of Example 1, the modified packing used in the exhaust gas bio-trickling filter tower of this example was tested for the adsorption capacity of degrading bacteria. The modified packing of the bio-trickling filter tower has significantly enhanced the load capacity of the degrading bacteria, and its distribution coefficien...

Embodiment 3

[0033] The ceramsite is screened to obtain raw materials with a particle size of 5-100mm. After washing with water, put the washed ceramsite in 1.0molL -1 After soaking in aqueous hydrochloric acid solution for 12 hours, rinse thoroughly, and then use a concentration of 1.0molL -1 Soak in NaOH aqueous solution for 12 hours, take out the ceramsite and wash with water until neutral. Then the ceramsite was dried at 100°C and placed in 100mgL -1 Immerse in D-polylysine aqueous solution for 10 minutes, drain and dry at 90°C, and then it becomes the modified filler for waste gas biological trickling filter tower.

[0034] According to the method of Example 1, the modified packing used in the exhaust gas bio-trickling filter tower of this example was tested for the adsorption capacity of degrading bacteria. The modified packing of the bio-trickling filter tower has significantly enhanced the load capacity of the degrading bacteria, and its distribution coefficient Kd value of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com